Introduction

Computer Numerical Control (CNC) machines have revolutionized modern manufacturing by providing precise, automated control of machine tools. Understanding the functions and operations of CNC machines is essential for anyone working in manufacturing, engineering, or related fields. This comprehensive guide covers the core functions, operational procedures, safety protocols, and maintenance requirements of CNC machines.

1. Core Functions of CNC Machines

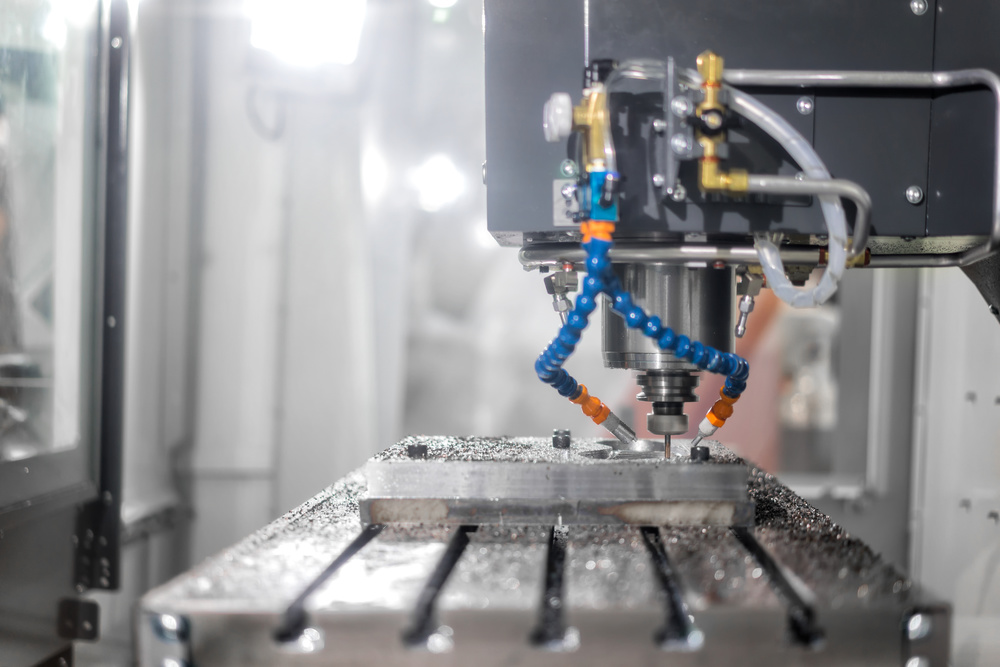

1.1 Material Removal Capabilities

CNC machines perform various material removal operations with high precision and repeatability:

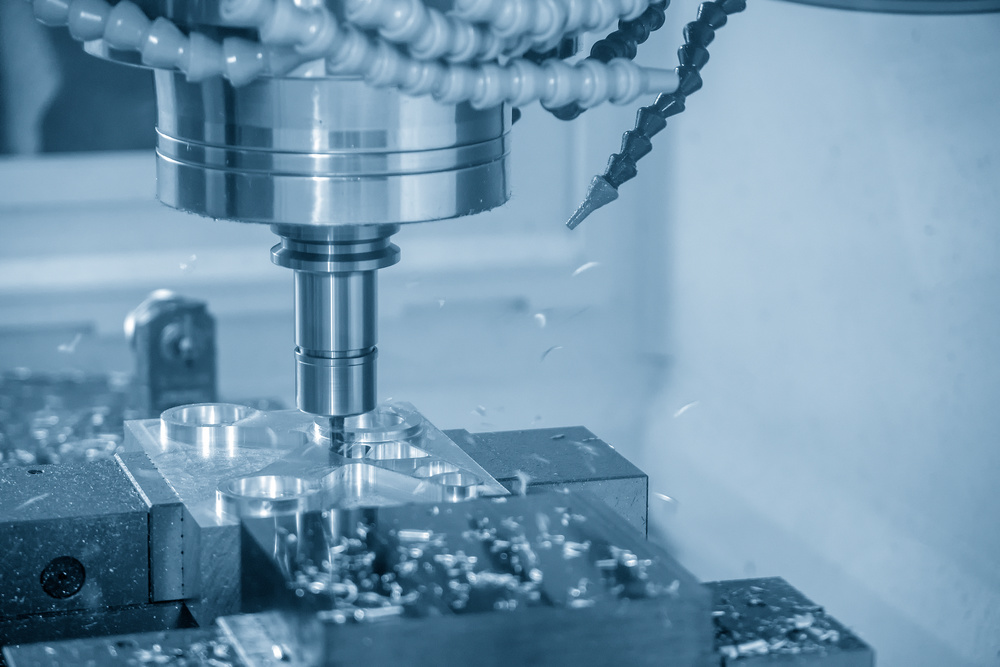

Milling Operations:

- Face Milling: Creating flat surfaces on the workpiece

- Peripheral Milling: Cutting along the edges of the workpiece

- End Milling: Creating slots, pockets, and contours

- Drilling and Tapping: Creating holes and threads

- Boring: Enlarging existing holes to precise dimensions

Turning Operations:

- Facing: Creating flat surfaces on rotational parts

- Turning: Reducing the diameter of cylindrical parts

- Threading: Creating external and internal threads

- Grooving: Cutting grooves and recesses

- Knurling: Creating textured surfaces for grip

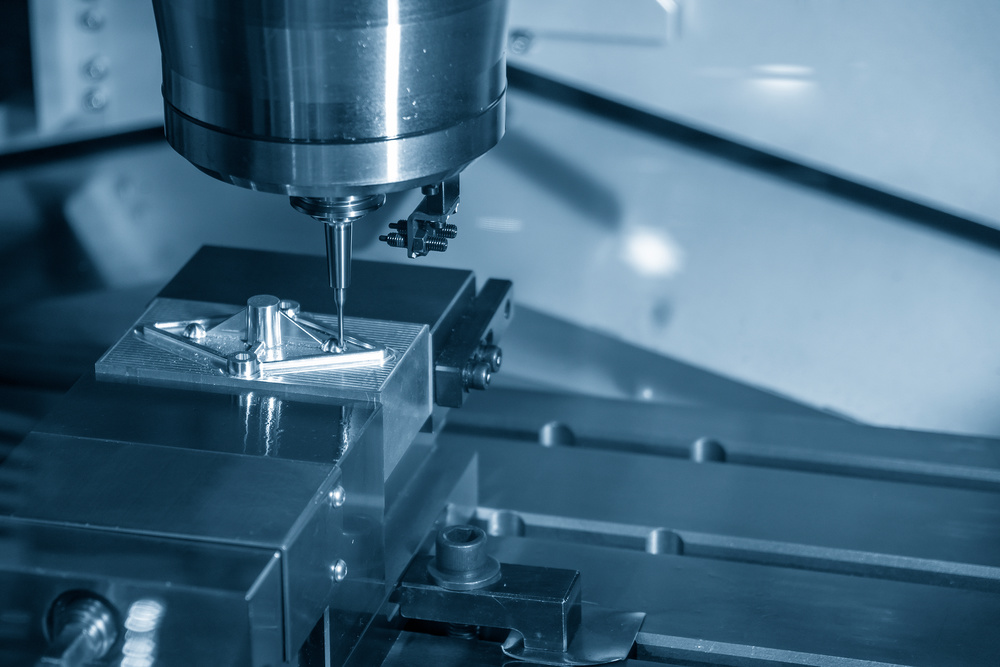

Advanced Machining Functions:

- 5-Axis Machining: Complex contouring and multi-sided machining

- High-Speed Machining: Rapid material removal with reduced heat

- Micro-Machining: Precision machining of small components

- Deep Hole Drilling: Creating deep, straight holes with high accuracy

1.2 Precision Control Features

CNC machines incorporate advanced control features to ensure precision:

Closed-Loop Feedback Systems:

- Real-time position monitoring using encoders and sensors

- Automatic error correction for accurate positioning

- Constant velocity control for smooth motion

- Adaptive feed rate adjustment based on cutting conditions

Tool Management Systems:

- Automatic tool changing capabilities

- Tool length and diameter compensation

- Tool wear monitoring and compensation

- Tool life management and optimization

Workpiece Handling:

- Automatic workpiece clamping and unclamping

- Multiple workpiece fixturing capabilities

- Pallet changing systems for continuous production

- Robotic integration for unattended operation

1.3 Automation and Integration Functions

Programmable Automation:

- Computer-aided programming (CAM) integration

- Offline programming and simulation

- Program storage and retrieval

- Batch processing capabilities

Manufacturing Integration:

- Network connectivity for production monitoring

- Data collection for process optimization

- Integration with manufacturing execution systems (MES)

- Industry 4.0 compatibility for smart manufacturing

2. CNC Control Panel Operation

2.1 Control Panel Components

The CNC control panel is the primary interface between the operator and the machine:

Display Unit:

- LCD/CRT Screen: Shows program status, coordinates, and diagnostics

- Graphical Display: Visual representation of toolpaths and machining processes

- Status Indicators: Machine state, alarms, and operational modes

Input Devices:

- MDI Keyboard: Manual data input for program editing

- Function Keys: Quick access to common functions

- Axis Control Buttons: Manual movement of machine axes

- Knobs and Dials: Speed, feed rate, and spindle speed adjustment

Control Buttons:

- Emergency Stop: Immediate shutdown in emergency situations

- Cycle Start/Stop: Begin and pause machining operations

- Reset: Reset the CNC system and clear alarms

- Mode Selection: Auto, Manual, MDI, and Jog modes

2.2 Key Operational Modes

CNC machines offer different operational modes to accommodate various tasks:

Automatic Mode (AUTO):

- Full automatic execution of pre-programmed part programs

- Continuous operation without manual intervention

- Ideal for production runs and batch processing

- Real-time monitoring of machining parameters

Manual Data Input (MDI):

- Manual entry of G-code commands for single operations

- Useful for testing specific machining functions

- Quick adjustments and modifications

- Small production runs and prototyping

Jog Mode:

- Manual movement of machine axes using buttons or handwheel

- Controlled positioning for setup and alignment

- Adjustable feed rates for precise movements

- Tool setup and workpiece alignment

Handwheel Mode:

- Precise manual positioning using a handheld pulse generator

- Micro-adjustments for critical alignments

- Variable increment settings (0.001mm to 1mm)

- Ideal for tool setting and workpiece alignment

2.3 Essential Control Functions

Coordinate System Management:

- Machine Coordinates: Fixed reference system based on machine home position

- Work Coordinates: User-defined coordinate systems (G54-G59)

- Relative Coordinates: Temporary coordinate system for specific operations

- Tool Coordinates: Tool length and radius compensation values

Program Management:

- Program Editing: Modifying existing programs

- Program Storage: Saving programs to memory or external devices

- Program Verification: Checking for syntax errors and collisions

- Program Execution: Starting, pausing, and resuming program runs

Parameter Setting:

- Feed Rate Override: Adjusting feed rates during operation

- Spindle Speed Override: Adjusting spindle speeds as needed

- Rapid Traverse Override: Controlling rapid movement speeds

- Coolant Control: Turning coolant on/off manually or automatically

3. Basic Operational Procedures

3.1 Machine Startup and Initialization

Proper startup procedures ensure safe and efficient machine operation:

Pre-Startup Inspection:

- Power Check: Verify main power supply and emergency stop functionality

- Fluid Levels: Check coolant, lubrication, and hydraulic fluid levels

- Machine Condition: Inspect for damage, loose components, or obstructions

- Tool Condition: Check tool holders and cutting tools for wear or damage

- Workpiece Preparation: Ensure workpiece is clean and properly sized

Machine Startup Sequence:

- Power On: Turn on main power switch and control system

- System Initialization: Wait for CNC system to boot up

- Home Positioning: Perform reference return to establish machine zero

- System Check: Verify no alarms or error messages are present

- Parameter Verification: Confirm machine parameters are correct

3.2 Workpiece Setup and Alignment

Workpiece Mounting:

- Clean Fixtures: Ensure clamping surfaces are clean and free of debris

- Workpiece Installation: Securely mount workpiece in appropriate fixture

- Clamping Verification: Ensure workpiece is properly clamped and secure

- Runout Check: Verify workpiece is aligned correctly with machine axes

Work Offset Setting:

- Edge Finding: Use edge finder to locate workpiece edges

- Touch Probing: Use touch probe for automatic offset setting (if available)

- Manual Setting: Manually set work offsets using dial indicators

- Offset Verification: Double-check offset values before machining

3.3 Tool Setup and Compensation

Tool Installation:

- Tool Selection: Choose appropriate tools for machining operations

- Tool Mounting: Install tools in tool holders with proper tightening

- Tool Length Setting: Measure and input tool length offsets

- Tool Diameter Setting: Measure and input tool radius compensation values

Tool Verification:

- Tool Position Check: Verify tool is properly seated in spindle

- Tool Length Verification: Confirm tool length offsets are correct

- Tool Diameter Verification: Check tool radius compensation values

- Test Cut: Perform test cut to verify tool settings

3.4 Program Loading and Execution

Program Preparation:

- Program Selection: Choose appropriate part program from memory or external device

- Program Review: Check program for errors or potential issues

- Toolpath Simulation: Simulate program to verify toolpaths

- Collision Detection: Check for potential collisions between tool and workpiece

Program Execution:

- Dry Run: Execute program without cutting to verify operation

- Single Block: Run program one block at a time for initial verification

- Cycle Start: Begin automatic machining operation

- Process Monitoring: Continuously monitor machining process

In-Process Adjustments:

- Feed Rate Adjustment: Modify feed rates based on cutting conditions

- Spindle Speed Adjustment: Change spindle speeds as needed

- Tool Offset Adjustments: Make fine adjustments to tool offsets

- Emergency Actions: Know when and how to stop or pause machining

4. Safety Procedures and Best Practices

4.1 Personal Safety Requirements

Personal Protective Equipment (PPE):

- Safety Glasses: Protection from flying debris and coolant

- Hearing Protection: Protection from machine noise

- Safety Shoes: Steel-toed shoes for foot protection

- Protective Clothing: Fitted clothing, no loose sleeves or jewelry

- Gloves: Only when handling sharp materials, never during machine operation

Safe Work Practices:

- Machine Familiarization: Understand machine capabilities and limitations

- Clear Communication: Establish communication protocols in shared workspaces

- Focused Attention: Maintain concentration during machine operation

- No Distractions: Avoid distractions while machine is running

- Training Requirements: Ensure proper training before operating equipment

4.2 Machine Safety Features

Emergency Controls:

- Emergency Stop Button: Immediate shutdown in emergency situations

- E-Stop Circuit: Redundant safety circuit for emergency stops

- Door Interlocks: Prevent machine operation when safety doors are open

- Override Controls: Limited access to safety overrides

Monitoring Systems:

- Overload Protection: Prevent damage from excessive cutting forces

- Temperature Monitoring: Detect abnormal operating temperatures

- Vibration Monitoring: Identify potential machine issues

- Smoke Detection: Early warning of potential fires

4.3 Operational Safety Protocols

Pre-Operation Checks:

- Machine Condition: Inspect machine for any signs of damage or wear

- Safety Devices: Verify all safety devices are functioning properly

- Workpiece Security: Ensure workpiece is properly clamped

- Tool Condition: Check tools for wear or damage

- Program Verification: Verify program is correct for the job

During Operation:

- Maintain Safe Distance: Keep hands and body clear of moving parts

- Monitor Machine Operation: Watch for any abnormal sounds or vibrations

- Avoid Reaching: Never reach into machine while it’s running

- Use Proper Tools: Use appropriate tools for setup and adjustments

- Keep Area Clean: Maintain clean and organized work area

Emergency Procedures:

- Emergency Stop: Know location and operation of emergency stop buttons

- Evacuation Routes: Know emergency evacuation routes

- First Aid: Know location of first aid equipment

- Reporting Incidents: Properly report all safety incidents

- Shutdown Procedures: Follow proper shutdown procedures in emergencies

5. Troubleshooting Common Issues

5.1 Programming Errors

Common Programming Issues:

- Syntax Errors: Incorrect G-code or M-code formatting

- Coordinate Errors: Incorrect work offsets or tool offsets

- Toolpath Errors: Invalid tool movements or collisions

- Parameter Errors: Incorrect feed rates or spindle speeds

Diagnostic and Correction:

- Error Messages: Read and understand CNC system error messages

- Program Review: Carefully review program for syntax errors

- Toolpath Simulation: Use simulation to visualize tool movements

- Dry Run: Execute program without cutting to verify operation

- Incremental Testing: Test program in small sections

5.2 Machining Quality Issues

Surface Finish Problems:

- Rough Surfaces: Excessive feed rates or dull tools

- Chatter Marks: Vibrations during machining

- Tool Marks: Incorrect tool geometry or speeds

- Burn Marks: Excessive cutting temperatures

Dimensional Accuracy Issues:

- Size Errors: Incorrect tool offsets or workpiece setup

- Form Errors: Machine calibration or rigidity issues

- Position Errors: Backlash or wear in machine components

- Repeatability Issues: Inconsistent performance

Correction Strategies:

- Tool Inspection: Check tools for wear and replace if necessary

- Parameter Adjustment: Optimize feed rates and spindle speeds

- Machine Calibration: Check and adjust machine calibration

- Setup Verification: Double-check workpiece setup and clamping

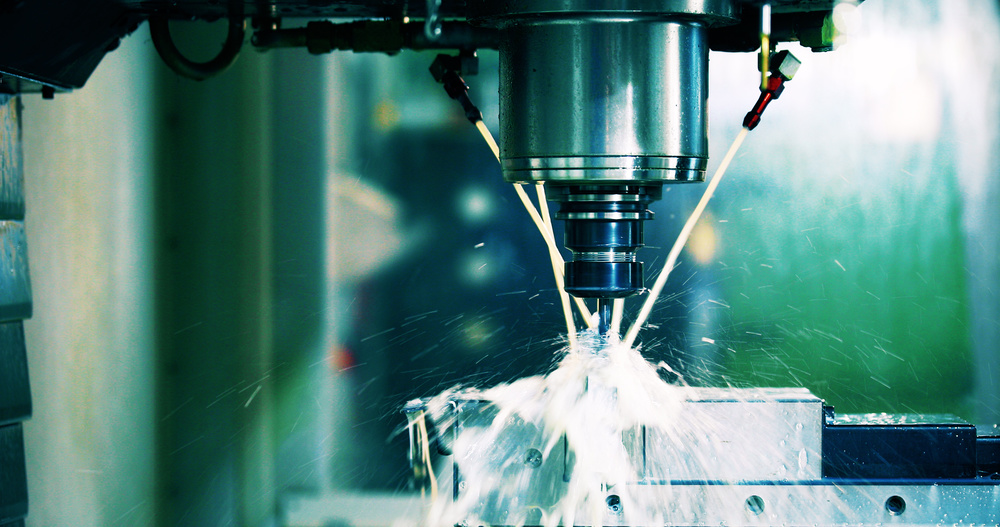

- Coolant Optimization: Ensure proper coolant flow and concentration

5.3 Machine Malfunctions

Mechanical Issues:

- Spindle Problems: Abnormal spindle noise or vibration

- Axis Movement: Jerky or inconsistent axis movements

- Tool Changer: Issues with automatic tool changing

- Clamping: Problems with workpiece clamping

Electrical Issues:

- Control System: CNC system errors or crashes

- Motor Problems: Servo motor or spindle motor issues

- Sensor Issues: Faulty position sensors or encoders

- Wiring Problems: Damaged or loose electrical connections

Troubleshooting Process:

- Problem Identification: Clearly identify the issue and symptoms

- Documentation: Document error messages and observed behavior

- Initial Checks: Perform basic checks of machine components

- System Diagnostics: Use CNC system diagnostic tools

- Component Testing: Test individual components as needed

- Repair or Replacement: Repair or replace faulty components

- Verification: Verify repair by testing machine operation

6. Maintenance and Care

6.1 Daily Maintenance Tasks

Machine Inspection:

- Visual Inspection: Check for any signs of damage or wear

- Fluid Levels: Check coolant, lubrication, and hydraulic fluid levels

- Filter Check: Inspect coolant and lubrication filters

- Safety Devices: Verify safety devices are functioning properly

Cleaning Procedures:

- Chip Removal: Clean chips from machine and work area

- Coolant System: Clean coolant tank and lines

- Guideways: Clean and lubricate machine guideways

- Control Panel: Clean control panel and display

Functional Checks:

- Axis Movement: Check for smooth axis movement

- Spindle Operation: Verify spindle runs smoothly at various speeds

- Tool Changer: Test automatic tool changing functionality

- Workpiece Clamping: Check clamping systems for proper operation

6.2 Preventive Maintenance

Regular Maintenance Schedule:

- Daily: Basic cleaning and inspection

- Weekly: Detailed inspection and lubrication

- Monthly: Comprehensive maintenance and calibration

- Quarterly: Major maintenance and component checks

- Annually: Complete machine overhaul and calibration

Lubrication Requirements:

- Guideways: Proper lubrication for smooth movement

- Ball Screws: Regular lubrication to prevent wear

- Bearings: Proper lubrication for long life

- Gears: Lubrication for quiet and efficient operation

Calibration and Alignment:

- Axis Alignment: Check and adjust axis alignment

- Backlash Compensation: Measure and adjust backlash

- Spindle Alignment: Check spindle runout and alignment

- Tool Length Setting: Verify tool length compensation

6.3 Long-Term Care Considerations

Component Replacement:

- Tool Holders: Replace worn or damaged tool holders

- Cutting Tools: Regular replacement of cutting tools

- Filters: Replace coolant and lubrication filters

- Belts and Chains: Replace worn belts and chains

- Bearings: Replace worn bearings as needed

Environmental Factors:

- Temperature Control: Maintain stable operating temperature

- Humidity Control: Control humidity to prevent corrosion

- Dust Protection: Protect machine from excessive dust

- Vibration Isolation: Minimize external vibrations

Software Maintenance:

- System Updates: Keep CNC software up to date

- Backup Programs: Regularly back up part programs

- Parameter Backup: Backup machine parameters

- Diagnostic Software: Use diagnostic software for preventive maintenance

7. Advanced Operational Techniques

7.1 High-Speed Machining

High-Speed Machining Principles:

- Increased Spindle Speeds: Higher RPM for faster material removal

- Optimized Feed Rates: Higher feed rates to match spindle speeds

- Light Depth of Cut: Smaller depths of cut with higher speeds

- Tool Path Optimization: Smooth tool paths to reduce vibration

Benefits and Considerations:

- Increased Productivity: Faster machining cycles

- Improved Surface Finish: Reduced cutting forces and heat

- Extended Tool Life: Optimized cutting parameters

- Machine Requirements: Rigid machine structure required

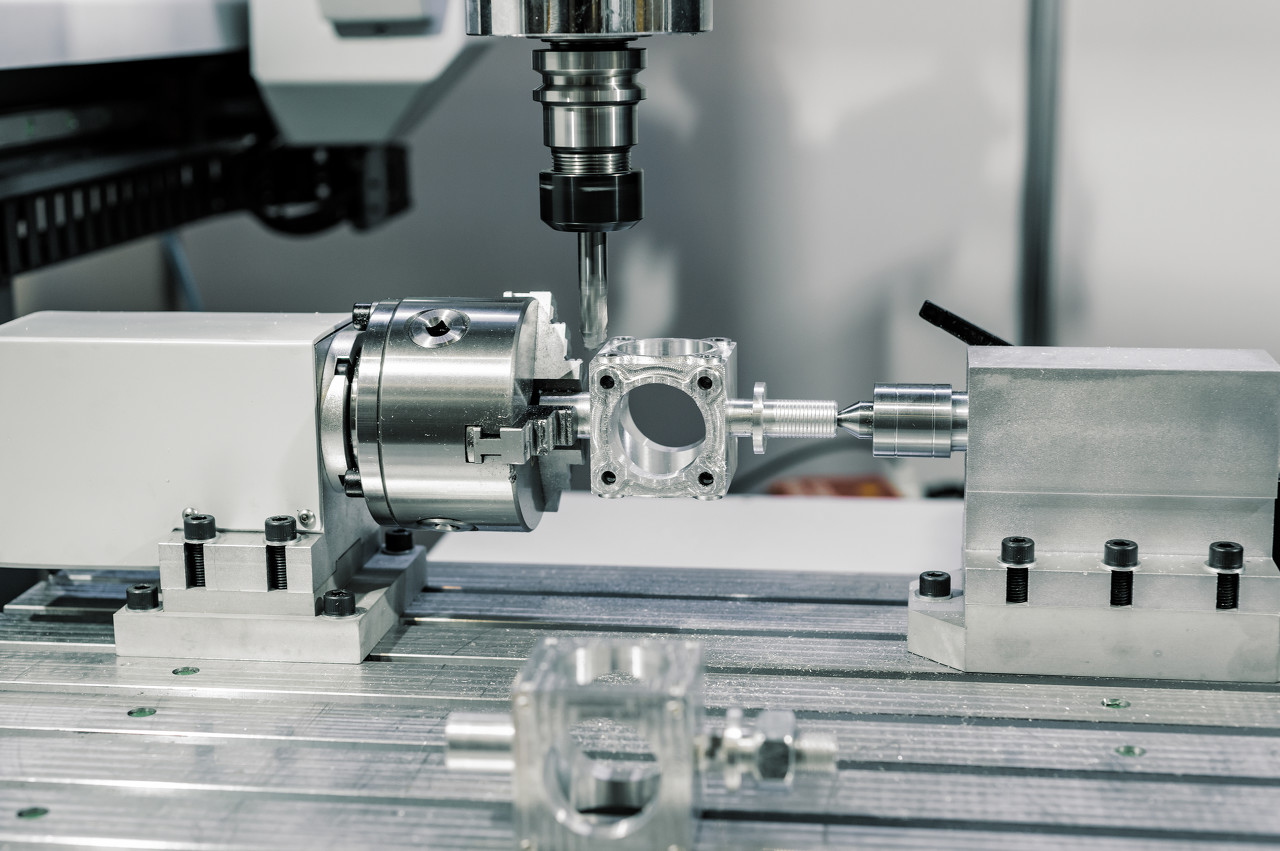

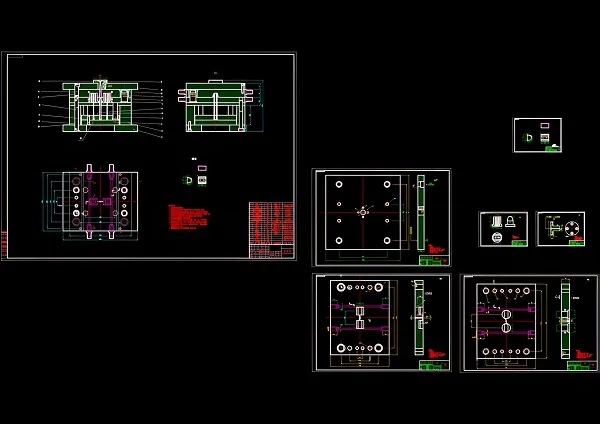

7.2 Multi-Axis Machining

5-Axis Machining Capabilities:

- Complex Geometry: Machining of complex 3D shapes

- Single Setup Machining: Complete parts in one setup

- Reduced Fixturing: Less need for complex fixturing

- Improved Access: Better access to complex features

Programming Considerations:

- Tool Orientation: Managing tool orientation in 3D space

- Collision Avoidance: Preventing collisions in multi-axis space

- Post-Processing: Specialized post-processors for 5-axis machines

- Simulation: Advanced simulation for verification

7.3 Automation Integration

Robotic Integration:

- Machine Tending: Robotic loading and unloading of workpieces

- Tool Management: Automated tool handling and storage

- Quality Inspection: In-line inspection with robots

- Material Handling: Automated material transport

Unattended Operation:

- Program Scheduling: Automatic scheduling of machining jobs

- Error Recovery: Automatic error detection and recovery

- Remote Monitoring: Remote monitoring of machine status

- Production Tracking: Real-time production tracking and reporting

8. Training and Skill Development

8.1 Essential Skills for CNC Operators

Technical Skills:

- Blueprint Reading: Understanding engineering drawings and specifications

- Mathematics: Basic math and geometry for machining calculations

- Metrology: Using precision measuring tools

- Material Science: Understanding material properties and behaviors

Machine Skills:

- Machine Operation: Proficiency in machine setup and operation

- Programming: Basic G-code programming and editing

- Tool Selection: Choosing appropriate tools for different materials

- Parameter Setting: Setting feed rates, spindle speeds, and offsets

Problem-Solving Skills:

- Troubleshooting: Identifying and solving machining problems

- Process Optimization: Improving machining processes

- Quality Control: Ensuring parts meet quality standards

- Decision Making: Making informed decisions during machining

8.2 Training Programs and Certifications

Formal Training Options:

- Technical Schools: Vocational and technical school programs

- Community Colleges: Associate degree programs in manufacturing

- Manufacturer Training: Training programs from machine manufacturers

- Online Courses: Web-based training and certification programs

Certification Programs:

- NIMS Certification: National Institute for Metalworking Skills

- Manufacturer Certifications: Certifications from machine manufacturers

- Industry Certifications: Various industry-specific certifications

- Continuing Education: Ongoing training for skill development

8.3 Career Development Paths

Entry-Level Positions:

- CNC Operator: Basic machine operation and setup

- Machine Tender: Monitoring and basic operation

- Apprentice Machinist: Learning trade through apprenticeship

Advanced Positions:

- CNC Programmer: Creating and optimizing CNC programs

- CNC Setup Technician: Complex machine setup and tooling

- Manufacturing Engineer: Process development and optimization

- CNC Supervisor: Managing CNC operations and personnel

9. Industry Applications and Trends

9.1 Key Industry Applications

Aerospace Industry:

- Complex Components: Machining of complex aerospace components

- Tight Tolerances: Precision machining for critical applications

- Advanced Materials: Machining of titanium, composites, and superalloys

- Quality Requirements: Stringent quality control and documentation

Automotive Industry:

- High-Volume Production: Mass production of automotive components

- Just-In-Time Manufacturing: Quick response to production needs

- Cost Efficiency: Optimized processes for cost reduction

- Advanced Materials: Lightweight materials for fuel efficiency

Medical Device Manufacturing:

- Biocompatible Materials: Machining of materials suitable for medical use

- Micro-Machining: Precision machining of small medical components

- Regulatory Compliance: Meeting FDA and other regulatory requirements

- Customization: Patient-specific medical devices

9.2 Emerging Technologies and Trends

Industry 4.0 Integration:

- Smart Manufacturing: Connected and intelligent manufacturing systems

- Internet of Things (IoT): Connected machines and devices

- Big Data Analytics: Using data for process optimization

- Artificial Intelligence: AI-powered process optimization and predictive maintenance

Advanced Materials Machining:

- Additive Manufacturing: Combining 3D printing with CNC machining

- Composite Machining: Machining of composite materials

- Ceramic Machining: Precision machining of ceramic components

- Metal Matrix Composites: Machining of advanced composite materials

Automation Advancements:

- Collaborative Robots: Working alongside human operators

- Autonomous Systems: Self-operating manufacturing systems

- Digital Twin Technology: Virtual simulation of manufacturing processes

- Augmented Reality: AR-assisted maintenance and operation

10. Conclusion and Best Practices

10.1 Summary of Key Points

CNC machine functions and operations encompass a wide range of capabilities and techniques:

Core Functions:

- Precision material removal through various machining processes

- Advanced control features for accuracy and repeatability

- Automation capabilities for increased productivity

- Integration with modern manufacturing systems

Operational Excellence:

- Proper setup and calibration procedures

- Adherence to safety protocols and best practices

- Effective troubleshooting and problem-solving

- Regular maintenance and care

Skill Development:

- Continuous learning and skill improvement

- Understanding of advanced technologies

- Adaptability to changing manufacturing requirements

- Commitment to quality and safety

10.2 Best Practices for CNC Operations

For Operators:

- Safety First: Always prioritize safety in all operations

- Continuous Learning: Stay updated with new technologies and techniques

- Attention to Detail: Pay close attention to setup and operation details

- Quality Focus: Maintain focus on producing high-quality parts

- Communication: Communicate effectively with team members

For Organizations:

- Invest in Training: Provide comprehensive training for personnel

- Implement Standards: Establish and follow standard operating procedures

- Maintain Equipment: Regular maintenance for reliable operation

- Embrace Technology: Adopt new technologies for improved performance

- Foster Culture: Create culture of continuous improvement and safety

10.3 Future Outlook

The future of CNC machining is shaped by technological advancements and industry needs:

Technological Advancements:

- Increased automation and intelligence

- Improved precision and capabilities

- Enhanced connectivity and integration

- Development of new materials and processes

Industry Evolution:

- Shift toward smart manufacturing

- Increased customization and flexibility

- Focus on sustainability and efficiency

- Global competition and collaboration

By mastering CNC machine functions and operations, manufacturers can achieve higher productivity, better quality, and greater competitiveness in today’s global manufacturing environment. Continuous learning and adaptation to new technologies will be key to success in the evolving world of CNC machining.

Frequently Asked Questions (FAQ)

Q: What are the main functions of a CNC machine?

A: CNC machines perform precision material removal operations including milling, turning, drilling, tapping, and complex contouring. They offer automated control, high precision, and repeatability for manufacturing components.

Q: What is the difference between CNC milling and turning?

A: CNC milling uses rotating cutting tools to remove material from stationary workpieces, while CNC turning rotates the workpiece against stationary cutting tools. Milling is better for complex shapes, while turning excels at cylindrical parts.

Q: What safety precautions are essential for CNC operation?

A: Essential safety precautions include wearing appropriate PPE, maintaining safe distances from moving parts, verifying machine condition before operation, understanding emergency stop procedures, and following proper setup and operation protocols.

Q: How do I troubleshoot common CNC programming errors?

A: Common programming errors include syntax errors, coordinate errors, and toolpath errors. Troubleshooting steps include reviewing error messages, checking program syntax, simulating toolpaths, performing dry runs, and testing incrementally.

Q: What maintenance is required for CNC machines?

A: CNC machines require regular maintenance including daily cleaning and inspection, weekly lubrication, monthly calibration, quarterly component checks, and annual overhauls. Proper maintenance ensures reliable operation and extends machine life.

Q: What skills are needed to operate CNC machines?

A: CNC operators need skills in blueprint reading, basic mathematics, metrology, machine operation, programming fundamentals, tool selection, and problem-solving. Continuous learning is essential to keep up with new technologies.

Q: What are the career opportunities in CNC machining?

A: Career opportunities include CNC operator, programmer, setup technician, manufacturing engineer, and supervisor positions. With experience and additional training, operators can advance to more specialized and higher-paying roles.

Q: How is Industry 4.0 impacting CNC machining?

A: Industry 4.0 is bringing IoT connectivity, big data analytics, AI optimization, and smart manufacturing capabilities to CNC machining, enabling greater automation, efficiency, and productivity.

Q: What are the latest trends in CNC machining technology?

A: Latest trends include 5-axis machining, high-speed machining, additive manufacturing integration, collaborative robotics, digital twin technology, and increased focus on sustainability and energy efficiency.

Q: How can I improve my CNC machining skills?

A: Improve CNC skills through formal training programs, manufacturer certifications, on-the-job experience, online courses, technical publications, and participation in industry events and workshops.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.