Introduction

In the ever – evolving landscape of modern manufacturing, CNC machining and engineering stand as cornerstones, revolutionizing the way products are designed, prototyped, and mass – produced. From the precision – crafted components in aerospace machinery to the intricate parts within our everyday electronics, the influence of CNC machining and engineering is omnipresent.

CNC, which stands for Computer Numerical Control, represents a marriage between advanced computer technology and traditional machining processes. It enables machines to execute highly precise operations based on pre – programmed instructions, eliminating many of the inaccuracies and inefficiencies associated with manual machining. Engineering, on the other hand, plays a crucial role in the entire lifecycle of a product. It encompasses the initial design phase, where concepts are translated into detailed blueprints, and extends to the optimization of manufacturing processes to ensure cost – effectiveness, quality, and sustainability.

This article will delve deep into the world of CNC machining and engineering. We will explore the fundamental principles that underpin CNC technology, the diverse range of CNC machining processes available, and how engineering concepts are applied to enhance the overall manufacturing experience. Whether you are a manufacturing professional looking to expand your knowledge, an engineer interested in the latest advancements, or simply someone curious about the inner workings of modern manufacturing, this article aims to provide valuable insights into the fascinating realm of CNC machining and engineering.

What is CNC Machining and Engineering

1. Definition of CNC Machining

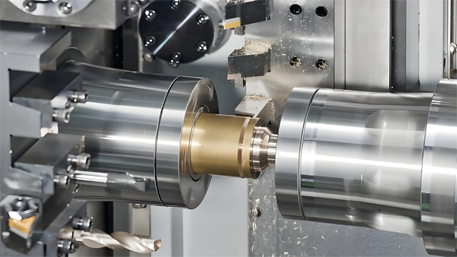

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process that uses pre – programmed computer software to control the movement of factory tools and machinery. In a traditional machining setup, an operator manually controls the machine tools, such as lathes, mills, and routers, to remove material from a workpiece to create a desired shape. However, in CNC machining, this manual control is replaced by a computer – controlled system.

The process begins with the creation of a digital design, often in the form of a 3D model or a 2D drawing, using Computer – Aided Design (CAD) software. This design is then translated into a set of numerical instructions, which are the G – codes and M – codes. These codes are the language that the CNC machine understands. They specify details such as the movement of the cutting tool, the speed at which it should operate, the depth of cuts, and the feed rate.

Once the code is generated, it is sent to the CNC machine’s controller. The controller interprets the code and sends signals to the various motors and actuators in the machine. These components then move the workpiece and the cutting tool with extreme precision, often to tolerances as tight as ±0.001 inches or even less in some high – precision applications. This high level of precision makes CNC machining ideal for producing complex parts with consistent quality, whether it’s a small component for a watch or a large part for an aircraft engine.

2. Role of Engineering in CNC Machining

Engineering plays a multifaceted and indispensable role in the realm of CNC machining.

Design Engineering: At the very beginning of a project, design engineers use CAD software to create detailed models of the parts to be produced. They take into account factors such as the part’s functionality, aesthetics, and manufacturability. For example, in designing a component for a medical device, the engineer must ensure that the part meets strict biocompatibility standards, has a smooth surface finish for proper function, and can be produced efficiently using CNC machining. The design engineer also has to consider the limitations of the CNC machines, such as the maximum size of the workpiece, the available cutting tools, and the range of motion of the axes. By optimizing the design for CNC machining, they can reduce production time and costs while ensuring high – quality output.

Process Engineering: Process engineers are responsible for developing the most efficient and effective manufacturing processes for CNC machining. They select the appropriate cutting tools, determine the optimal cutting parameters (such as spindle speed, feed rate, and depth of cut), and plan the sequence of operations. For instance, when machining a complex aluminum alloy part, the process engineer needs to choose the right type of end – mill based on the part’s geometry, set the spindle speed high enough to achieve efficient material removal but not so high as to cause overheating and tool wear. They also plan the machining operations in a logical order, perhaps starting with rough machining to remove large amounts of material quickly and then finishing with fine machining to achieve the desired surface finish and dimensional accuracy.

Quality Engineering: Quality engineers play a crucial role in ensuring that the parts produced by CNC machining meet the required quality standards. They develop inspection plans and use various metrology tools and techniques to measure the dimensions of the machined parts. Coordinate Measuring Machines (CMMs) are often used to accurately measure the part’s features and compare them to the design specifications. If any deviations are detected, the quality engineer works with the design and process engineers to identify the root cause, which could be anything from a worn – out cutting tool to an incorrect machine setting. By implementing quality control measures at every stage of the CNC machining process, they can prevent defective parts from being produced and ensure that the final products are reliable and of high quality.

In summary, engineering in CNC machining is about the careful planning, design, and control of the manufacturing process to produce high – quality parts efficiently and cost – effectively.

Key Aspects of CNC Machining and Engineering

1. Precision and Accuracy

One of the most remarkable features of CNC machining is its ability to achieve an extremely high level of precision and accuracy. CNC machines can consistently hold tolerances as tight as ±0.0002 inches (±0.00508 mm) in many high – end applications. This level of precision is far beyond what is achievable with traditional manual machining methods.

In traditional machining, human factors such as operator fatigue, skill level, and the physical limitations of manual control can introduce significant variations in the dimensions of the machined parts. For example, in manual milling, an operator might struggle to maintain a consistent cut depth, leading to a deviation in the final part’s thickness. In contrast, a CNC milling machine, guided by its pre – programmed instructions, can execute the same cut with the same depth repeatedly, ensuring that each part produced is virtually identical in dimensions.

The high precision of CNC machining is crucial in industries where even the slightest deviation can have catastrophic consequences. In the aerospace industry, components like turbine blades for jet engines must be manufactured with extreme accuracy. A small error in the shape or dimensions of a turbine blade could lead to imbalances during operation, reducing engine efficiency, increasing fuel consumption, and potentially causing engine failure. CNC machining allows for the production of these critical components with the necessary precision to meet the strictest aerospace standards.

2. Versatility in Material and Design

CNC machining is highly versatile when it comes to the materials it can process and the designs it can bring to life.

Materials: CNC machines can work with a vast array of materials. In the realm of metals, common materials include aluminum, which is popular for its lightweight properties and is widely used in the automotive and aerospace industries. Aluminum is easy to machine, has good thermal conductivity, and can be alloyed to enhance its strength for various applications. Steel, especially stainless steel, is another commonly machined metal. Stainless steel’s corrosion – resistance makes it ideal for applications in the medical, food processing, and marine industries. Copper, valued for its excellent electrical conductivity, is often used in the production of electrical components. Titanium, with its high strength – to – weight ratio and exceptional corrosion resistance, is a preferred material for aerospace and medical implant applications.

Beyond metals, CNC machining can also handle a variety of plastics such as ABS (Acrylonitrile Butadiene Styrene), which is known for its good impact resistance and is commonly used in the production of consumer electronics casings. Polycarbonate, with its high strength and optical clarity, is used in applications like automotive lighting and safety equipment. Even more exotic materials like carbon fiber composites, which are prized for their high strength and low weight, can be machined using specialized CNC techniques. These composites are widely used in high – performance sports equipment, such as racing bicycles and golf clubs, as well as in aerospace and automotive applications.

Design: CNC machining has the capability to turn the most complex design concepts into reality. Thanks to its multi – axis capabilities, parts with intricate geometries, undercuts, and complex curves can be produced. For example, in the mold – making industry, molds for injection – molded plastic parts often have complex internal cavities and detailed surface textures. CNC machining allows for the precise creation of these molds, ensuring that the final plastic parts accurately replicate the desired design. Another example is the production of custom – designed jewelry. CNC milling machines can carve out elaborate patterns and shapes in precious metals, creating unique and high – quality jewelry pieces that would be extremely difficult to produce by hand.

3. Efficiency and Productivity

CNC machining offers significant advantages in terms of efficiency and productivity. The automation inherent in CNC technology reduces the need for extensive manual intervention. Once the program is set up and the machine is running, it can operate continuously for long periods, producing parts with consistent quality.

For instance, consider a small – scale manufacturing operation that produces mechanical components. Before implementing CNC machining, the production process involved a skilled operator manually controlling a lathe to turn each part. This process was time – consuming, and the operator needed to take regular breaks, limiting the number of parts that could be produced in a day. After switching to CNC machining, the operator simply loads the raw material, starts the pre – programmed cycle, and monitors the machine. The CNC lathe can run non – stop for hours, producing parts at a much faster rate. In some cases, the production cycle for a particular part can be reduced from several minutes in manual machining to just a few seconds in CNC machining, leading to a substantial increase in productivity.

Moreover, CNC machining allows for the use of advanced machining strategies such as high – speed machining and multi – axis simultaneous machining. High – speed machining enables the removal of material at a much faster rate, reducing the overall machining time. Multi – axis machining, on the other hand, allows for the completion of multiple operations in a single setup. For example, a five – axis CNC machine can machine a complex part from all sides without the need to re – position the workpiece, saving time and reducing the potential for errors associated with multiple setups. This not only increases productivity but also improves the quality of the final product by minimizing the cumulative errors that can occur during multiple re – positionings.

Applications of CNC Machining and Engineering

1. Aerospace Industry

In the aerospace industry, CNC machining and engineering are of utmost importance. The manufacturing of aircraft and spacecraft requires components that can withstand extreme conditions, from the high – pressure and high – temperature environments within jet engines to the harsh vacuum of space.

CNC machining is used to create critical components such as turbine blades, which are essential for the operation of jet engines. These blades are designed with complex aerodynamic shapes to optimize the engine’s efficiency. CNC milling machines, with their high – precision capabilities, can accurately carve out the intricate curves and profiles of turbine blades from high – strength materials like nickel – based superalloys. For example, in the production of a modern turbofan engine, the compressor blades are often machined using five – axis CNC milling. The multi – axis capabilities allow for the creation of blades with variable pitch and twist along their length, which significantly improves the engine’s performance by enhancing the compression ratio and reducing aerodynamic losses.

Another application is in the production of aircraft structural components. The fuselage and wing structures are made up of numerous parts, such as spars, ribs, and stringers. CNC machining ensures that these parts are produced with the highest precision, enabling a perfect fit during the assembly process. This not only improves the structural integrity of the aircraft but also reduces the weight, which is crucial for fuel efficiency. For instance, the Boeing 787 Dreamliner makes extensive use of CNC – machined components, with many parts being made from lightweight yet strong aluminum – lithium alloys. The precise machining of these components has contributed to the aircraft’s improved fuel efficiency and longer range.

2. Medical Field

The medical field greatly benefits from the precision and reliability offered by CNC machining and engineering. CNC – machined parts are used in a wide range of medical devices, from surgical instruments to implantable devices.

In the case of surgical instruments, CNC machining allows for the production of highly precise and ergonomic tools. For example, laparoscopic instruments, which are used in minimally invasive surgeries, require fine – tuned precision. CNC – milled forceps, scissors, and graspers have smooth edges and accurate jaw alignments, enabling surgeons to perform delicate procedures with greater control. These instruments are often made from stainless steel or titanium, materials that are biocompatible and resistant to corrosion, ensuring the safety and longevity of the tools.

CNC machining is also essential in the production of implantable devices. Hip and knee implants, for instance, are designed to replace damaged joints and improve the quality of life for patients. These implants are typically made from titanium alloys or cobalt – chrome alloys. CNC machining ensures that the implants have the correct shape, size, and surface finish. The precise machining of the implant’s surface can enhance osseointegration, the process by which the implant fuses with the surrounding bone tissue. A well – machined hip implant will have a surface texture that promotes the growth of bone cells, reducing the risk of implant loosening over time. Dental implants are another example. CNC – machined dental implants are made to fit precisely into the jawbone, providing a stable foundation for artificial teeth. The high – precision manufacturing ensures that the implants match the patient’s unique anatomy, leading to better long – term success rates.

3. Automotive Sector

In the automotive industry, CNC machining and engineering play a crucial role in the production of high – performance and reliable vehicles. The manufacturing of engines, transmissions, and other critical components relies heavily on CNC technology.

Engine components such as cylinder heads, crankshafts, and pistons are typically produced using CNC machining. Cylinder heads, which house the valves and fuel injectors, require precise machining to ensure proper combustion and engine performance. CNC milling machines are used to create the complex internal passages for the intake and exhaust gases, as well as the accurate seating surfaces for the valves. For example, in high – performance engines, the ports in the cylinder head are carefully designed and machined to optimize the flow of air – fuel mixture into the combustion chamber, improving engine power and efficiency.

Transmission components, including gears, shafts, and housings, also benefit from CNC machining. Gears, in particular, need to be manufactured with extreme precision to ensure smooth operation and minimal noise. CNC gear – hobbing machines can produce gears with tight tolerances, ensuring proper meshing and power transfer. The shafts that connect the gears are also precisely machined to maintain the correct alignment and balance. In modern automatic transmissions, the complex valve bodies that control the flow of hydraulic fluid are often CNC – machined. These valve bodies have intricate channels and orifices that are precisely drilled and milled to ensure accurate shifting and efficient operation of the transmission.

Moreover, CNC machining is used in the production of automotive prototypes. Before mass – production, automakers use CNC – machined prototypes to test and validate new designs. This allows them to identify and address any design flaws early in the development process, reducing the time and cost associated with bringing a new vehicle to market. For example, a concept car’s body panels may be CNC – machined from lightweight materials like aluminum or carbon – fiber – reinforced plastics. These prototypes can be used for aerodynamic testing in wind tunnels and for evaluating the overall aesthetics and functionality of the design.