In modern manufacturing, CNC machining (Computer Numerical Control Machining), with its high precision, high efficiency, and flexibility, has become a core technology that bridges product design and actual production. As an industry leader, Goldcattle provides customers with full – cycle CNC machining services, from rapid prototyping to large – scale production, through the coordination of automated factories and a global manufacturing network. Its technical capabilities cover key aspects such as material selection, process optimization, surface treatment, and quality control.

I. Core Processes: Technical Characteristics and Application Scenarios of Milling and Turning

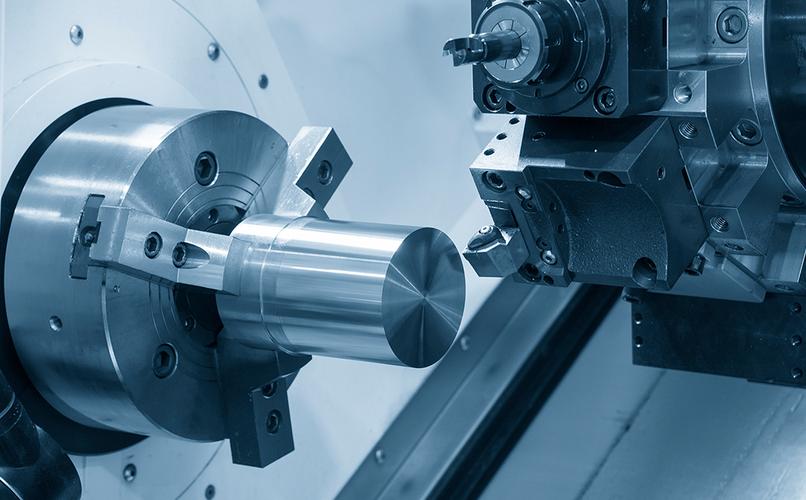

CNC machining is based on the principle of subtractive manufacturing. It achieves precise cutting of metal or plastic blanks by controlling the tool path through computer programs. Goldcattle’s two core processes are as follows:

CNC Milling

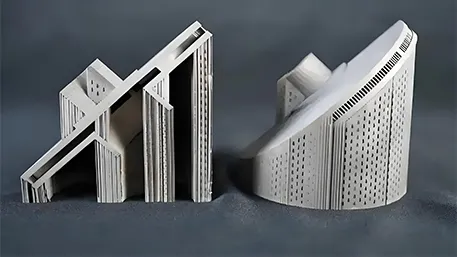

3 – axis Milling: It is suitable for processing basic structures like planes, grooves, and bosses. The standard tolerance is ±0.005 inches (approximately ±0.13mm), which is suitable for rapid prototyping. For instance, consumer – electronics casings or simple mechanical parts can be completed within 1 – 3 days via 3 – axis milling.

5 – axis Indexing Milling: By adding rotational axes (A/C axes), it can machine complex curved surfaces, reducing the number of clamping operations and improving precision. Typical applications include turbine blades in the aerospace field and artificial joints in the medical industry. The minimum feature size can reach 0.5mm.

CNC Turning

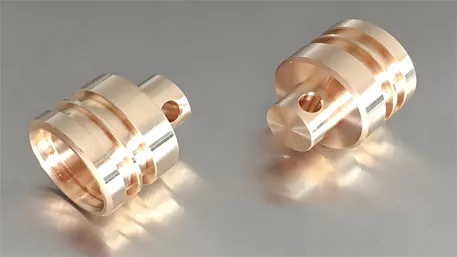

With the rotation of the spindle and the linear movement of the tool, it can machine the outer diameter, inner diameter, and threads of shaft – type parts. Goldcattle’s turning capacity can handle workpieces with a maximum diameter of 17 inches (431mm) and a length of 39 inches (990mm). It is applicable to cylindrical – feature parts such as automotive drive shafts and bearing sleeves. When combined with powered tools, it can perform compound machining such as radial milling.

II. Material Selection: Performance Adaptation of Metals and Engineering Plastics

Goldcattle offers over 30 industrial – grade materials to meet diverse needs from prototyping to mass production:

Metal Materials

Aluminum Alloys (6061/7075): They are the first choice for lightweighting, combining strength and cutting efficiency. They are widely used in UAV frames and automotive suspension components.

Stainless Steels (316L/17 – 4PH): These are corrosion – resistant and high – strength, suitable for medical implants (such as orthopedic screws) and food – processing equipment.

Titanium Alloys (Grade 5): With a high strength – to – weight ratio, they are used for aerospace engine compressor blades. However, attention should be paid to the tool wear problem caused by their low thermal conductivity.

Engineering Plastics

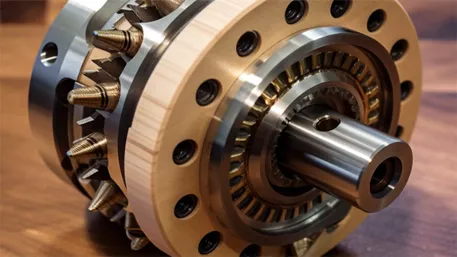

PEEK: It is resistant to high temperatures (260°C) and chemical corrosion. It can replace metals in precision gears in semiconductor equipment.

Polycarbonate (PC): It has high transparency and impact resistance and is often used in optical lenses and protective casings for electronic devices.

Delrin (POM): It has low friction and high wear resistance and is an ideal material for mechanical bearings and gears.

III. Precision Control: The Synergistic Advantages of the Tolerance System and the Manufacturing Network

Goldcattle meets different precision requirements through a hierarchical manufacturing system:

Automated Factories: The standard tolerance is ±0.005 inches (±0.13mm), which is suitable for rapidly iterating prototyping, with the fastest delivery within 1 day.

Traditional Factories: The tolerance is improved to ±0.002 inches (±0.05mm), which is suitable for small – batch production with higher precision requirements.

Global Manufacturing Network: It supports a precision tolerance of ±0.001 inches (±0.02mm), meeting the strict requirements for dimensional consistency in fields such as aerospace and medical equipment. For example, the network’s capabilities can machine a minimum feature size of 0.5mm, meeting the manufacturing needs of miniature gears or electronic connectors.

IV. Surface Treatment: The Dual Value of Function Enhancement and Aesthetic Optimization

Surface treatment not only improves the appearance of parts but also endows them with specific functions:

Protective Treatments

Anodizing (Type II/III): It is a standard process for aluminum – alloy parts. The Type III hard anodized layer can reach a thickness of 25 – 100μm, significantly enhancing wear resistance. It is suitable for the guide rails of sports equipment.

Chrome/Nickel Plating: It enhances the corrosion resistance of stainless – steel parts and is often used on the surfaces of marine equipment or medical devices.

Functional Treatments

PTFE – Impregnated Coating: By embedding polytetrafluoroethylene in the anodized layer, a self – lubricating surface is formed, reducing the friction coefficient to less than 0.05. It is suitable for high – load sliding components.

Electropolishing: Through an electrochemical process, the surface roughness is reduced (the Ra value is reduced from 125μin to 32μin), improving the inner – wall finish of medical catheters and reducing the risk of liquid retention.

Decorative Treatments

Powder Coating: It provides a matte or high – gloss texture and supports customization according to the RAL color card. It is widely used for the visual optimization of consumer – electronics casings.

Laser Marking: It achieves permanent marking of part serial numbers or QR codes, meeting the traceability requirements of the automotive supply chain (such as the IATF 16949 standard).

V. Application Scenarios: Manufacturing Flexibility across Industries

CNC machining shows unique value in different industries:

Aerospace: It machines titanium – alloy wing ribs and stainless – steel fasteners, meeting AS9100D certification requirements and ensuring the reliability of parts in extreme environments.

Medical Equipment: It uses medical – grade stainless steel (such as 316L) and PEEK materials to manufacture surgical instruments and implants that meet ISO 13485 standards and supports sterilization treatment.

Automotive Industry: It can rapidly produce aluminum – alloy transmission casings and nylon gears, adapting to the development cycle of prototype vehicles and enabling rapid delivery of small batches of 1 – 200 pieces.

Consumer Electronics: It machines precision aluminum – alloy mobile – phone mid – frames through 5 – axis milling. Combining with the anodizing process, it balances the metallic texture and signal compatibility.

VI. Design Guidelines: Key Principles for Manufacturability and Cost Optimization

To improve processing efficiency and reduce costs, the following should be noted during design:

Geometric Features

Avoid closed undercut structures. If necessary, use component splitting or 5 – axis machining.

The inner – corner radius should be ≥0.018 inches (0.457mm) to match standard tool sizes and reduce the use of special tools.

Material Removal Efficiency

The depth – to – diameter ratio of deep – cavity structures is recommended to be ≤6:1 to avoid accuracy loss caused by long – tool vibration.

For batch production, use the “multi – part – from – one – material” layout, such as machining multiple shaft – type parts from the same aluminum rod, to reduce material waste.

Tolerance Allocation

Use loose tolerances (such as ±0.010 inches) for non – mating surfaces and mark strict tolerances for key mating features (such as bearing holes). Tolerance optimization can reduce processing costs by 30%.

VII. Conclusion: The Manufacturing Efficiency Revolution Driven by Technology Integration

Goldcattle, through the seamless connection between automated factories and the global manufacturing network, has upgraded CNC machining from a traditional “precision – processing method” to a “full – cycle manufacturing solution.” Whether it is a rapid prototype or a precision part with a tolerance of ±0.001 inches, its technical system always revolves around the three core elements of “precision, speed, and cost.” For engineers, rationally choosing materials, processes, and surface – treatment solutions, and combining with manufacturability design principles, can maximize the potential of CNC machining and promote the efficient transformation of products from concept to reality. In the future, with the application of AI – driven process optimization and Internet – of – Things technology, CNC machining will be more deeply integrated into the intelligent manufacturing ecosystem, becoming a key hub connecting additive manufacturing and automated assembly.