Brass is one of the easiest materials to machine due to its high machinability, good ductility, flexibility, and high feed rate. Typical grades include C36000, C35330, and CW507L, among which C36000 is recognized as the brass material with the best machinability. CNC machining of brass can produce high – quality brass components with extremely high precision and an aesthetic surface finish. It helps in the production of parts such as lamps, pipes, fittings, flared fittings, gears, etc. Brass has a variety of good mechanical properties, including a low coefficient of friction, strong wear resistance, high corrosion resistance, ductility, and malleability.

In the field of CNC machining, the selection of materials plays a crucial role in the performance of parts, processing efficiency, and cost control. Brass, as a metal material with excellent mechanical properties and machining feasibility, is widely used in the manufacturing of various precision parts due to its outstanding cutting performance, good corrosion resistance, and stable dimensional accuracy.

I. Characteristics of Brass Suitable for CNC Machining

Outstanding Machinability

Brass is one of the most easily machined metals, mainly due to the lead content in its composition. Brass has good ductility, a high feed rate, and low processing resistance, making it an ideal material for CNC machining. Precisely because of this characteristic, brass has become one of the most widely used metal materials in CNC machining.

Excellent Corrosion Resistance

Brass has good corrosion – resistant properties, which is another important advantage for various processing projects. The excellent corrosion resistance not only extends the service life of brass – made tools or parts but also makes it suitable for applications in wet or liquid environments. However, the corrosion – resistant performance of brass may vary depending on the content of elements such as iron and aluminum in its alloy.

Good Ductility

Due to its high copper content, brass has excellent ductility, even better than pure copper. This characteristic makes brass easy to form during processing, facilitating the machining of various complex geometric shapes. Therefore, brass is very suitable for the CNC machining of customized parts.

Certain Strength and Hardness

Although brass is very easy to machine, it still has good strength and durability. Although its strength is not as high as that of steel, for most regular applications, the strength of brass is completely sufficient to meet the load requirements of parts during use.

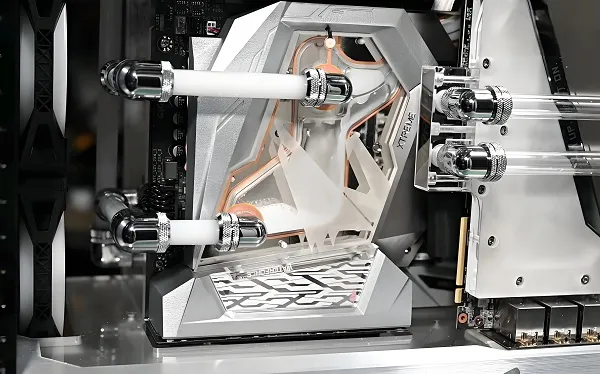

Outstanding Appearance

In many processing projects, the appearance of the finished product is also a key factor. Brass itself has a natural bright golden color and an elegant appearance, and it can be used directly without additional surface treatment. This natural visual beauty gives brass parts good decorative properties in addition to their functionality.

II. Applications of CNC Brass Manufacturing Processes

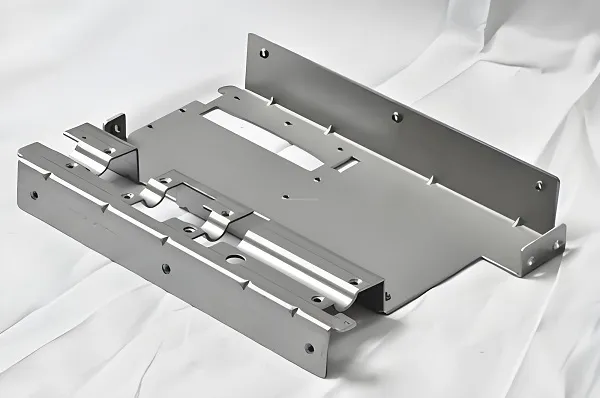

The brass manufacturing process plays an important role in many fields, especially in the manufacturing of customized parts such as electrical equipment, connectors, screws, and rotor bars. To ensure that the performance of brass components meets expectations, we need to consider multiple aspects:

First, choosing the appropriate brass grade is crucial. Different applications have different requirements for the properties of brass. For example, in electrical applications, the excellent electrical conductivity and corrosion resistance of brass make it the first choice, and usually, brass with a high copper content is selected.

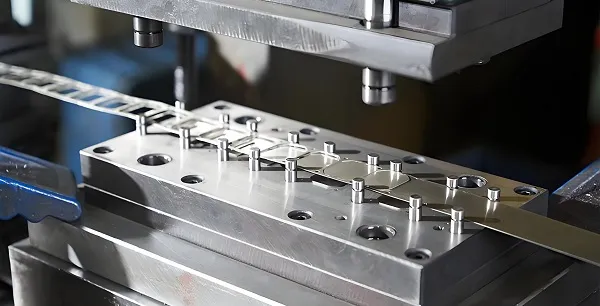

Secondly, strict control of processing accuracy is required. CNC machining technology can precisely control the shape and size of brass components to ensure they meet design specifications. Especially in high – precision fields such as aviation and medical devices, the dimensional accuracy is crucial to the performance of components.

In addition, corrosion resistance is also a factor that cannot be ignored. For brass components used in wet or chemically corrosive environments, their corrosion resistance directly affects the service life. For example, brass C230 is suitable for plumbing equipment and marine environments due to its high corrosion resistance.

At the same time, the golden luster of brass components also has good visual appeal, making them shine in decorative products. Through processes such as polishing and electroplating, their aesthetics can be further enhanced, and they are widely used in the fields of architectural decoration and art.

Finally, when choosing the finishing method, it is necessary to ensure that the brass components are compatible with options such as polishing, electroplating, buffing, or powder coating to meet the needs of specific applications.

III. Key Points of CNC Machining of Copper Materials

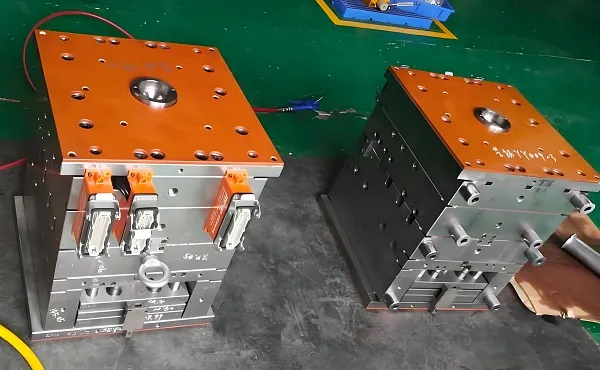

Correct Selection of Copper Material Grades

Before CNC machining, it is necessary to select the appropriate copper material grade according to specific application requirements. For example, using pure copper to manufacture mechanical parts is usually costly and has poor machinability, which is not ideal. In contrast, free – cutting copper (such as copper materials with a small amount of alloying elements) has better machinability and economy and is more suitable for machining. Therefore, the performance requirements of the parts should be fully evaluated, and the type of copper material should be reasonably selected.

Optimizing Part Design to Meet Manufacturing Requirements

Before processing, it is necessary to ensure that the part design conforms to the principle of Design for Manufacturability (DFM) to improve the functionality of the finished product and processing efficiency. It is generally recommended that the wall thickness of the part be controlled above 0.5mm to ensure structural stability and aesthetics.

In addition, reasonably simplifying the number of part clamping times and dimensional inspection requirements, and avoiding the design of features with high processing difficulty such as deep holes and small round corners, can help improve processing efficiency and the finished – product rate.

Reasonable Setting of Feed Rate

The feed rate directly determines the cutting state when the tool contacts the workpiece. Appropriately increasing the cutting speed and adopting medium – low feed rates can obtain better surface quality and reduce the tool load. Excessively high feed rates or too low cutting speeds are likely to cause tool built – up edges, affecting machining accuracy.

Selection of Appropriate Tool Materials

Copper is soft and highly ductile, which can easily lead to cutting edge wear or chip adhesion. During processing, sharp and wear – resistant tools should be selected, such as carbide tools. At the same time, the rake angle and clearance angle of the tool should be optimized to ensure smooth cutting and reduce chip – sticking phenomena.

IV. The Problem of Blackening of Copper Parts in the CNC Workshop

During the processing, we need to have overall control. First, adjusting the cutting parameters is the key. Although high – speed cutting can improve efficiency, for copper parts, too high a cutting speed may cause rapid surface oxidation. Therefore, the cutting parameters should be carefully adjusted to avoid severe friction and heat accumulation.

Secondly, select suitable tools and maintain them. Coated tools perform well in copper processing, especially TiAlN – coated tools, which can effectively reduce frictional heat and build a chemical isolation layer between the tool and copper to prevent oxidation reactions.

In addition, using a cutting fluid specifically for copper is also essential. For example, borate – type cutting fluids contain special anti – oxidation and corrosion – inhibiting components that can effectively protect copper parts from oxidation.

What if the copper parts have already turned black? Don’t worry, there are immediate treatment methods. In – situ emergency cleaning is the first step. Soak the parts in a weak – acid cleaning solution for 5 – 10 minutes to dissolve the black oxide layer on the surface. Then, rinse with clean water or blow – dry with high – pressure air to prevent further oxidation of the oxide layer.

For slight blackening flaws, a micro – grinding tool can be used for repair. Gently touch the surface of the part with a handheld micro – grinding tool, and the thin oxide layer will fall off. After restoring the brightness, wipe it clean with a soft cloth, and the dimensional accuracy is hardly affected.