In the aerospace field, the performance and precision of components are directly related to the safety and reliability of aircraft. Traditional processing methods often face problems such as insufficient precision, low efficiency, and unstable quality when dealing with aerospace – grade materials (such as titanium alloys and superalloys) and the requirements of complex structural parts. This article will analyze how to create a highly reliable aerospace CNC machining solution from the dimensions of service advantages, core processes, and quality assurance.

I. Why Can’t Traditional Machining Meet the Requirements of Aerospace Manufacturing?

Q&A: What are the core advantages of aerospace CNC machining services?

The particularity of aerospace component manufacturing brings three core pain points to traditional machining:

Unattainable precision requirements: Key components such as aero – engine blades and landing gear need to meet micron – level tolerances of ±0.003mm. The positioning accuracy of traditional machine tools is only ±0.05mm, and manual operation errors are large. The scrap rate is as high as 30%, which cannot meet the strict assembly and performance requirements.

Extremely high material processing difficulty: Aerospace materials such as titanium alloys and nickel – based superalloys have high hardness and poor thermal conductivity. Ordinary tools wear severely, the cutting speed is less than 30m/min, the processing efficiency is only 1/5 that of aluminum alloy, and the unit cost increases by 80% – 100%.

Limited processing of complex structures: Aerospace components mostly have thin – wall (wall thickness ≤ 0.5mm), deep – cavity, and twisted – surface structures. Traditional processing requires multiple clamping and sequential processing, resulting in large cumulative errors. Moreover, processing blind spots are likely to occur, making it difficult to ensure the structural integrity and precision.

However, aerospace CNC machining services focus on “high precision, high reliability, and high adaptability”:

Micron – level precision assurance: Using ultra – precision five – axis machining centers (positioning accuracy ±0.001mm), combined with on – line laser interference compensation technology, the dimensional tolerance of parts is controlled within ±0.003mm, and the surface roughness Ra ≤ 0.4μm, meeting the precision requirements of key aerospace components.

Customized special processes: In view of the characteristics of aerospace materials, special tools and processing parameters are developed, combined with processes such as cryogenic minimum quantity lubrication and electrical discharge machining. The processing efficiency is increased by 60%, and the tool life is extended to more than 15 hours.

Full – process quality traceability: From raw material inspection to finished – product delivery, a complete quality traceability system is established to ensure that each component is traceable and verifiable, with a product qualification rate of over 99.5%.

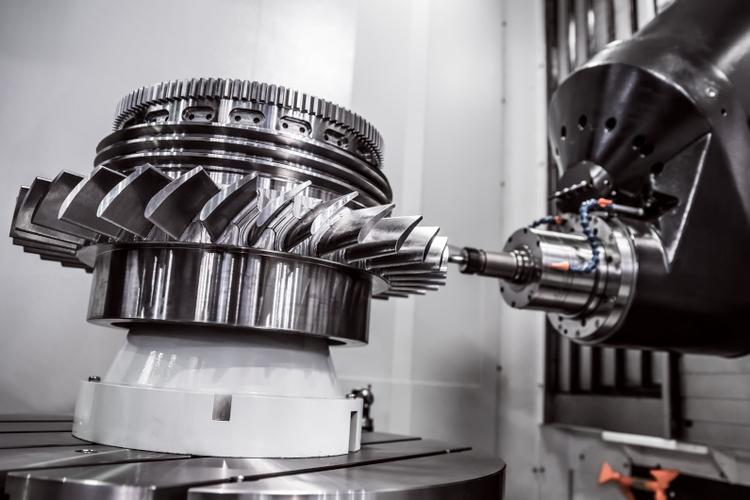

II. How to Achieve Precision Breakthroughs in the Core Processes of Aerospace CNC Machining?

Ultra – precision machining equipment and special tools

High – end machining equipment: Equipped with five – axis ultra – precision machining centers (spindle radial run – out ≤ 0.0003mm) and slow – wire electrical discharge machining machines (electrode wire wear < 0.001mm). Adopt air – floating guideways and hydrostatic bearing technologies to reduce mechanical vibration and achieve nanometer – level cutting (minimum cutting depth 0.1μm).

Aerospace – specific tools: Use super – hard tools such as CBN (cubic boron nitride) and PCD (polycrystalline diamond). Optimize the edge radius (minimum 0.01mm) and rake and clearance angle parameters for titanium alloys and superalloys. The cutting force is reduced by 40%, and the tool life is extended to 8 times that of ordinary tools. The surface is coated with a TiAlN nano – coating (thickness 1 – 2μm) to improve wear resistance and anti – adhesion.

Intelligent tooling system: Develop vacuum – adsorption fixtures (vacuum degree ≥ – 95kPa) and thermal – expansion fixtures. Achieve micron – level clamping and positioning through the principle of thermal expansion and contraction. For thin – wall blades, use elastic support structures and multi – point flexible clamping to control the clamping deformation within 0.001mm.

Digital special processing techniques

Micro – milling and micro – machining: For small parts (size < 5mm) such as aero – engine fuel nozzles and micro – structures (aperture 0.1mm, groove width 0.05mm), use micro – milling technology (spindle speed 100,000rpm), combined with a microscopic vision system and a servo motor with nanometer – level resolution, to achieve sub – micron – level machining accuracy.

Cryogenic minimum quantity lubrication processing: When processing titanium alloys and nickel – based alloys, use a composite cooling method of – 20℃ cryogenic cold air (flow rate 15L/min) and a small amount of lubricating oil (0.05ml/min) to suppress material deformation caused by cutting heat, reduce tool wear, and reduce the residual stress on the processed surface by 70%.

Electrical discharge machining (EDM): For complex surfaces, deep small holes (aperture ≤ 0.5mm), and hard materials, use EDM technology. Through the electrode wear compensation algorithm (accuracy ±0.003mm), achieve high – precision machining with a surface roughness Ra ≤ 0.8μm.

Intelligent machining control system

Digital twin pre – research: Use software such as ANSYS and UG NX to establish a digital twin model of parts, simulate the stress, strain, and temperature field distribution during the cutting process, optimize the tool path and cutting parameters, and eliminate more than 90% of potential machining errors in advance.

Real – time closed – loop control: The machine tool is equipped with a nanometer – level grating ruler (resolution 0.0001mm) and an acceleration sensor. Real – time collect position and vibration data. The AI algorithm automatically compensates for thermal deformation (compensation accuracy 0.0005mm) and tool wear (compensation amount 0.001mm) to ensure a stable machining process.

Cloud – based quality traceability: All machining data (process parameters, inspection reports, equipment status) are uploaded to the cloud in real – time. Customers can view the machining progress and quality data through an exclusive platform, realizing full – life – cycle traceability from raw materials to finished products.

III. Quality Control: Stringent Verification from Materials to Finished Products

Aerospace – grade testing system

Dimensional accuracy: Use a laser tracker (accuracy ±0.005mm) and a coordinate measuring machine (accuracy ±0.003mm) to detect key dimensions and geometric tolerances (roundness ≤ 0.002μm, flatness ≤ 0.003μm). For small – diameter holes, use CT scanning (resolution 1μm) for three – dimensional inspection.

Surface quality: Use a white – light interferometer (vertical resolution 0.1nm) to measure the surface roughness and microscopic morphology, and use an X – ray photoelectron spectrometer (XPS) to analyze the surface element composition and oxide layer thickness to ensure that the surface quality meets the design requirements.

Functional performance testing: Conduct aerodynamic performance tests on aero – engine blades and fatigue life tests on structural parts (simulating 10⁵ flight cycles) to verify the actual use performance.

Composition analysis: Use a spectrometer to detect the chemical composition of titanium alloys and superalloys, ensuring that the element content meets aerospace standards such as ASTM B265 and AMS 5550, and the impurity content (such as O ≤ 0.15%, N ≤ 0.03%) meets the standards.

Mechanical properties: Use a universal material testing machine to detect the tensile strength (≥1100MPa), yield strength (≥1000MPa), fatigue life (no fracture after 10⁷ cycles), and use a hardness tester to measure the Rockwell hardness (HRC 40 – 45) to ensure that the material properties meet aerospace requirements.

Metallographic inspection: Observe the microstructure of the material to ensure that the grain size is uniform (grain size ≥ 8 levels), and there are no segregation, inclusions, and other defects to guarantee the internal quality of the material.

Material – level verification:

Finished – product – level inspection:

Intelligent defect prevention mechanism

First – piece fifteen – inspection system: A professional team composed of process engineers and quality engineers conducts strict inspections of 50 indicators of the first – piece part, such as material batch, tool parameters, and processing dimensions. Use an electron microscope (magnification 1000 times) to detect micro – defects to ensure zero – error production.

Real – time process monitoring: Monitor abnormalities such as tool breakage and cutting chatter through an acoustic emission sensor (frequency range 100 – 1000kHz). Once a sudden change in the signal is detected, the system automatically stops and alarms within 0.1 seconds to prevent batch defects.

IV. How to Balance High Precision and Economy in Aerospace Machining?

Q&A: Does aerospace – grade precision necessarily come with high costs?

Through three innovative models, aerospace CNC machining achieves a cost reduction of 30% – 40% and an efficiency increase of 40%:

Intelligent tool life management: Deploy a tool health monitoring system, predict the tool life through cutting – force spectrum analysis (error < 3%), and automatically remind for tool change, reducing downtime by 25% and tool costs by 40%.

Process integration and optimization: Integrate multiple processes such as turning, milling, grinding, and electrical discharge machining in a compound machining center, reduce the number of clamping times, increase the machining efficiency by 40%, and at the same time reduce equipment investment and site occupation costs.

Cost reduction by digital twin: Use the digital twin model to replace 3 – 4 physical trial – cuts, saving 35% of material loss costs, shortening the R & D cycle by 15 – 20 days, and quickly responding to the needs of model development.

V. Core Considerations for Choosing an Aerospace CNC Machining Service

Equipment and technical barriers: The supplier should have ultra – precision machine tools, nanometer – level inspection equipment, and core processes such as micro – milling and magnetorheological polishing to ensure that it can meet the micron / nanometer – level processing requirements of the aerospace industry.

Industry certification qualifications: Have AS9100D aerospace quality management system certification, NADCAP certification, and CNAS – approved test reports to ensure that products meet international aerospace standards.

Digital service capabilities: Have digital tools such as digital twins, AI process optimization, and cloud – based traceability to achieve transparent and intelligent management of the whole process, ensuring processing quality and delivery cycle.

Conclusion

Aerospace CNC machining services, driven by technological innovation and data intelligence, break through the precision and efficiency bottlenecks of traditional machining, providing highly reliable component solutions for fields such as aero – engine manufacturing and aircraft structural part production. In the trend of the aerospace industry developing towards “higher performance and lower cost”, machining services with “ultra – precision equipment + digital twin process + aerospace – grade quality control” are becoming the core competitiveness for enterprises to break through technical blockades and seize the high – end manufacturing high – ground. From the precision blades of aero – engines to the key structural parts of spacecraft, aerospace CNC machining services will continue to help China’s aerospace industry reach new heights with nanometer – level precision and zero – defect quality.

(Contact us now to get a customized aerospace CNC machining solution and a free aerospace – grade precision inspection service)