- Precision and Motion Accuracy

- Positioning accuracy: Linear axes must achieve a positioning accuracy of ±0.005mm, and repeatability should be within ±0.002mm to ensure smooth and accurate robotic movements.

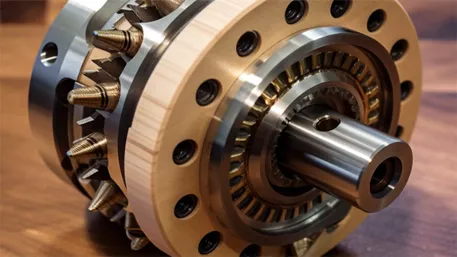

- Gear and transmission parts: Gear pitch error should be controlled within ±0.003mm, and tooth profile error within ±0.002mm to minimize motion errors and noise during operation.

- Load-Bearing and Durability

- Load capacity: Components such as robotic arms and joints need to withstand static loads of up to 500kg and dynamic loads of 300kg during operation, with a fatigue life of at least 1 million cycles under rated load conditions.

- Wear resistance: Surface hardness of sliding parts should reach 600 – 800HV, and the wear rate should be less than 0.001mm/1000 hours of operation to ensure long-term reliable operation.

- Environmental Adaptability

- Temperature resistance: Parts should maintain their mechanical properties within a temperature range of -40°C to 120°C. In high-temperature environments, the dimensional change rate should not exceed 0.1%, and in low-temperature environments, the impact toughness should not decrease by more than 15%.

- Corrosion resistance: For robots used in harsh environments like the ocean or chemical plants, components should pass a salt spray test of 1000 hours without corrosion and resist common chemical media such as acids, alkalis, and salts.

- Technical Advantages

- Complex geometry processing: 5-axis CNC machines can machine intricate shapes such as robotic arm joints with compound surfaces in one setup, achieving a machining accuracy of ±0.003mm. This reduces the number of setups and improves the overall machining efficiency and part accuracy.

- High surface finish: Capable of producing a surface roughness as low as Ra ≤ 0.4μm, which is crucial for parts that require smooth motion and reduced friction, such as linear guides and ball screws.

- Process Parameters

- Spindle speed: For aluminum alloy machining, the spindle speed can reach 15,000 – 20,000 rpm, while for titanium alloy, it is usually set at 5,000 – 8,000 rpm to balance machining efficiency and tool life.

- Feed rate: The feed rate varies depending on the material and machining operation. For rough machining of aluminum alloy, it can be 1000 – 2000 mm/min, and for finish machining, it is reduced to 200 – 500 mm/min to ensure dimensional accuracy and surface quality.

|

Process Type

|

Typical Application Scenarios

|

Technical Highlights

|

|

HSM for Aluminum

|

Lightweight robotic components (e.g., gripper fingers)

|

Machining speed increased by 3 – 5 times compared to conventional machining, surface finish improved by 30%

|

|

HSM for Titanium

|

High-strength parts in aerospace robots

|

Effectively reduces cutting forces, minimizes heat generation, and extends tool life by 2 – 3 times

|

- Internal Grinding: Used for machining the inner holes of components like bearing housings. It can achieve a roundness of ≤0.001mm and a surface roughness of Ra ≤ 0.2μm, ensuring a precise fit with bearings and reducing rotational friction.

- Surface Grinding: Ideal for flat surfaces of robotic base plates and mounting platforms. The parallelism of the ground surface can be controlled within ±0.002mm over a length of 100mm, providing a stable foundation for robotic assembly.

- Advantages: Suitable for machining hard and brittle materials or parts with complex internal structures, such as electrode – discharge – machined cavities in injection molds for robotic parts. It can achieve a machining accuracy of ±0.002mm and a surface roughness of Ra ≤ 0.8μm.

- Application: Used to create fine features and intricate geometries that are difficult to machine by traditional cutting methods, such as micro – channels in heat – dissipating components of robots.

- Multi-Dimensional Design Support

- Structural Optimization: Using finite element analysis (FEA) software like ANSYS, the stress distribution of robotic parts can be simulated. For example, in the design of a robotic arm, FEA can help optimize the thickness and shape of the arm structure, reducing stress concentrations by 40% and increasing the overall strength and durability.

- Function Customization: Custom – designed components can integrate sensors directly into the structure. For instance, strain gauges can be embedded in robotic joints to monitor real – time stress and strain, enabling predictive maintenance and improving the safety and reliability of the robot.

- Assembly Design: Design for assembly (DFA) principles are applied to ensure easy and accurate assembly of robotic parts. Interfaces between components are designed with precise tolerances and clear assembly instructions, reducing assembly time by 30% compared to non – optimized designs.

- Material Precision Selection

- Industrial Robots: Aluminum alloy 6061 is commonly used for general – purpose industrial robots due to its lightweight and cost – effectiveness. It is suitable for parts such as robotic arms and grippers that require good motion performance and moderate strength.

- Aerospace Robots: Titanium alloy Ti – 6Al – 4V is preferred for aerospace applications. Its high strength – to – weight ratio, excellent heat resistance, and corrosion resistance make it ideal for components used in harsh space environments, such as satellite – servicing robots.

- Medical Robots: Stainless steel 316 is widely used in medical robots because of its superior biocompatibility and corrosion resistance. It is used for parts that come into contact with the human body, such as surgical robotic instruments.

- Pre – processing Technology

- Material Annealing: Before machining, materials like titanium alloy are annealed at 850 – 900°C for 1 – 2 hours to relieve internal stress, reducing the risk of deformation during machining by 50%.

- Tool Coating: Tools are coated with materials such as titanium nitride (TiN) or titanium aluminum nitride (TiAlN). TiN coating can increase tool life by 2 – 3 times, and TiAlN coating, with its higher hardness and heat resistance, can further enhance tool performance, especially when machining high – temperature – resistant materials.

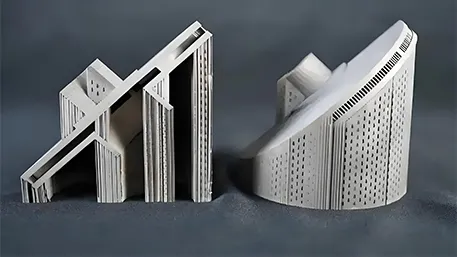

- Flexible Manufacturing Capability

- Rapid Prototyping: 3D printing technology is used for rapid prototyping of robotic parts. A prototype can be produced within 24 hours, allowing for quick design verification and reducing the development cycle by 40%. After the prototype is approved, CNC machining can be used for mass production.

- Small – Batch and Mass Production: For small – batch production (less than 100 pieces), 3 – axis or 4 – axis CNC machines can be used to balance cost and efficiency. For mass production, automated production lines with 5 – axis CNC machines and robotic loading/unloading systems are employed, with a daily production capacity of up to 1000 pieces for standard components.

- Comprehensive Inspection System

- Dimensional Inspection: Coordinate Measuring Machines (CMMs) are used to measure the dimensions of parts. The measurement accuracy of CMMs can reach ±0.001mm, ensuring that all parts meet the design requirements.

- Mechanical Performance Testing: Tensile testing, hardness testing, and fatigue testing are conducted. For example, tensile testing can verify whether the material’s strength meets the design standard, and fatigue testing can simulate the actual working conditions of the parts to ensure their long – term reliability.

- Certification Support: Products can obtain certifications such as ISO 9001, ISO 13485 (for medical robots), and AS9100 (for aerospace robots), meeting the quality requirements of different industries and ensuring market access.

- Assembly Line Robots: Components such as robotic arm links and gearboxes are machined with high precision. The arm links, made of aluminum alloy 6061, are 5 – axis CNC machined to achieve a lightweight yet strong structure. The gearboxes, with gears machined to high accuracy, ensure smooth and precise motion, improving the efficiency and accuracy of the assembly line.

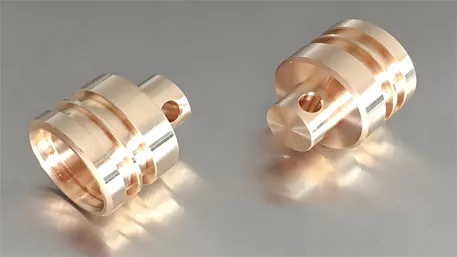

- Welding Robots: The electrodes and torch – holding components of welding robots are made of copper – based alloys and stainless steel. Precision machining techniques ensure good electrical conductivity and heat resistance of the electrodes, and the accurate fit of the torch – holding components guarantees stable welding quality.

- Surgical Robots: Surgical instruments and robotic arms used in minimally invasive surgeries are made of stainless steel 316. The parts are machined with ultra – high precision, with a surface roughness of Ra ≤ 0.1μm to reduce tissue adhesion and facilitate cleaning and sterilization. The high – precision machining also ensures the accuracy of the surgical movements, improving the success rate of surgeries.

- Rehabilitation Robots: Components of rehabilitation robots, such as joints and exoskeleton frames, are designed for comfort and functionality. Engineering plastics like POM are used for low – friction joints, and aluminum alloy is used for the frame to achieve a lightweight design. Precision machining ensures the smooth operation of the joints and the proper fit of the exoskeleton to the patient’s body.

- Satellite Servicing Robots: In space applications, where weight and reliability are critical, titanium alloy components are widely used. Parts such as robotic arms and grippers are machined with 5 – axis CNC technology to achieve complex geometries and high strength. The components can withstand the harsh space environment, including extreme temperatures and radiation, and perform precise operations on satellites.

- Lunar and Mars Exploration Robots: These robots need to be highly durable and adaptable to the harsh extraterrestrial environments. Aluminum alloy 7075 and titanium alloy are used for key components. High – speed machining and precision grinding techniques are employed to ensure the parts have high strength, low weight, and excellent wear resistance, enabling the robots to operate effectively on the lunar or Martian surface.