In modern manufacturing, product development, and creative realization, **precision** and **efficiency** are non-negotiable priorities. CNC machining service stands out as a pivotal bridge between design blueprints and physical parts—leveraging automated control, high stability, and flexibility to meet diverse needs, from small-batch prototyping to large-scale mass production across industries.

A professional CNC machining service is not limited to a single method; it combines diverse processes to adapt to different part structures, materials, and precision requirements. Key processes include:

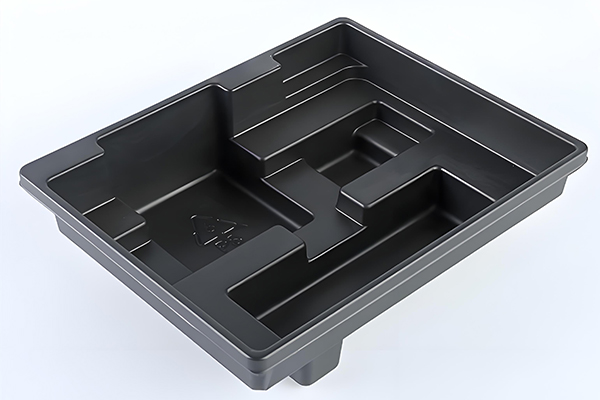

- CNC Milling: Ideal for flat surfaces, grooves, and complex curved structures. It processes multiple materials (metals, plastics, carbon fiber) and handles both simple small parts and complex industrial components.

- CNC Turning: Specialized for rotationally symmetric parts (e.g., shafts, disks). It enables high-precision machining of cylindrical or conical surfaces, commonly used for motor shafts, connectors, and custom fasteners.

- Multi-Axis CNC Machining: Breaks the limits of traditional machining via multi-axis linkage technology. It completes one-time processing of complex 3D structural parts, making it suitable for high-end fields like aerospace and robotics.

- Rapid Prototyping: Tailored for product development stages. It quickly transforms CAD drawings into physical prototypes, helping developers verify design feasibility and shorten R&D cycles.

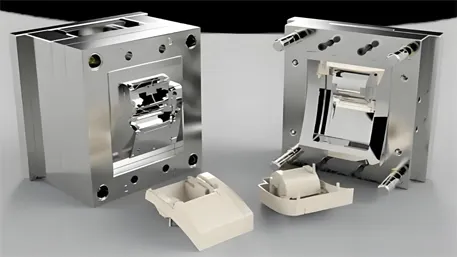

In addition, premium CNC machining services often include Design for Manufacturability (DFM) analysis—optimizing drawings before processing to avoid subsequent technical issues. They also support CNC machining for injection molds and die-casting molds, forming a full-chain solution from prototyping to mass production.

Compared to traditional manual processing or conventional mechanical machining, modern CNC machining service addresses core pain points in precision, efficiency, cost, and flexibility:

- High Precision & Stability: Controlled by computer programs, machining errors are reduced to the micron level. For batch production, parts maintain consistent quality, avoiding deviations caused by manual operations—critical for precision-sensitive scenarios like medical devices and aerospace parts.

- Fast Delivery: Automated workflows minimize manual intervention. Some CNC machining services offer “same-day shipping” for urgent orders, and lead times for regular prototypes or small-batch parts can be as short as 6 days, meeting tight R&D or production schedules.

- Wide Material Compatibility: It processes plastics, aluminum alloys, stainless steel, carbon fiber, titanium alloys, and more—supporting solutions for both ordinary industrial plastic parts and high-strength metal components.

- Flexible Batch Adaptability: It accommodates diverse volume needs, from “single small-part milling” for hobby projects to “thousand-unit mass production” for enterprises. Small-batch processing requires no high mold costs, lowering trial-and-error risks.

- Online Convenience: Most services support an end-to-end online process: “upload CAD files → get instant quotes.” Engineers and product developers can submit requests anytime, eliminating the need for offline communication and saving time.

CNC machining service is highly adaptable, catering to diverse user groups and industries:

- Industrial Manufacturing: Producing equipment parts, mechanical components, and supporting injection mold machining.

- High-End Sectors: Manufacturing “medical-grade CNC parts” for healthcare, “high-precision structural components” for aerospace/defense, and “custom accessories” for the automotive industry.

- Product R&D: Creating rapid prototypes to validate design feasibility and accelerate time-to-market.

- Hobby Projects: Custom small-part milling, avoiding high costs from large-scale factories.

- Startups: Low-cost prototyping to iterate product designs quickly.

To select a service that matches your needs, focus on these 4 key factors:

- Process Matching: Choose processes based on part structure (e.g., CNC turning for shafts, multi-axis machining for complex curved surfaces).

- Delivery Time: Prioritize “1–3 day delivery” for urgent needs; balance lead time and cost for regular orders.

- Precision Standards: Clarify your precision requirements (e.g., ±0.1mm for ordinary parts, ±0.01mm for high-end parts) and confirm the service provider’s capability to meet them.

- Material Support: Ensure the service can process your target material (special materials like carbon fiber or titanium alloy require specialized expertise).

For local needs, check “business hours” (e.g., 24/7 services for emergency machining) or use mapping tools to find nearby providers—facilitating offline communication and part handover.

Regular services process millimeter-scale parts, while high-precision services can handle micron-level structures. Specific capabilities depend on part complexity and material.

Services supporting online CAD uploads typically generate instant quotes within 10 minutes. Complex parts may require 1–2 business days for manual calculation.

Quality services implement a three-step inspection process: “first-part testing → in-process sampling → final full inspection.” Combined with the stability of automated equipment, this ensures parts stay within allowable error ranges for batch production.

Yes. Complete 2D/3D CAD files (e.g., STEP, IGES formats) help service providers accurately understand design requirements and avoid machining deviations.

CNC machining service has become the “infrastructure” of modern manufacturing and product development. Whether enterprises pursue “high-precision mass production” or individuals explore “creative prototyping,” professional services can turn needs into reality. When choosing, prioritize “process matching, precision compliance, and on-time delivery” over blind cost-cutting—this ensures CNC machining truly empowers your projects, reducing costs and time waste. For targeted solutions (e.g., specific part materials or industries), use the service provider’s online consultation tools to get technical support and customized quotes.