Industry Transformation and Opportunities Behind the Data

- Global Market Size: The global automotive metal precision parts market reached (286 billion in 2024 and is expected to exceed )310 billion by 2025, with a CAGR of 6.8% (Source: OICA – International Organization of Motor Vehicle Manufacturers)

- China Market Performance: The Chinese market exceeded RMB 840 billion in 2024 and is projected to approach RMB 1.4 trillion by 2030, with an annual growth rate of approximately 7.2% (Source: CAAM – China Association of Automobile Manufacturers)

- New Energy Transformation: The market share of new energy vehicle-related parts will rapidly increase from 34% in 2024 to over 58% by 2030 (Source: Deloitte Automotive Industry Report)

- Production Growth: China’s automobile production exceeded 32 million units in 2024, with new energy vehicles accounting for 35% of total production (Source: National Bureau of Statistics)

Core Technologies: Our Four Major Processing Advantages

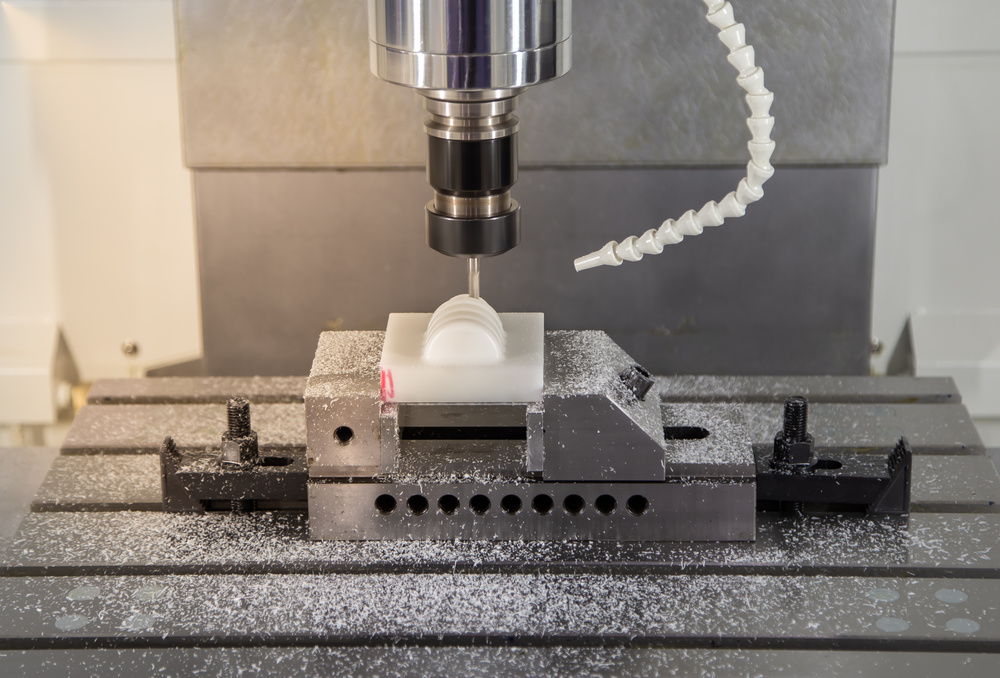

1. 5-Axis Simultaneous Precision Machining Technology

- One-time Forming of Complex Surfaces: Complex structures such as spiral oil cooling channels inside motor housings and inclined mounting surfaces

- Ultra-high Precision Control: According to ISO 230-2 standard, our positioning accuracy A ≤ 0.005mm, repeatability R ≤ 0.002mm

- Multi-process Integration: Completing milling, drilling, tapping and other processes in one setup, reducing clamping errors

2. Lightweight Material Processing Technology

- Aluminum Alloy Processing: The average aluminum usage per new energy vehicle in China reached 168kg in 2023, a 42% increase compared to 2020 (Source: IAI – International Aluminum Institute)

- Material Performance Optimization: Enhancing aluminum alloy strength to over 480MPa through ASTM standard heat treatment processes (T6, T7)

- Thin-walled Part Processing: Dimensional stability control for complex thin-walled structural parts, internal porosity controlled below 0.1%, complying with ASTM B970 cleanliness standard

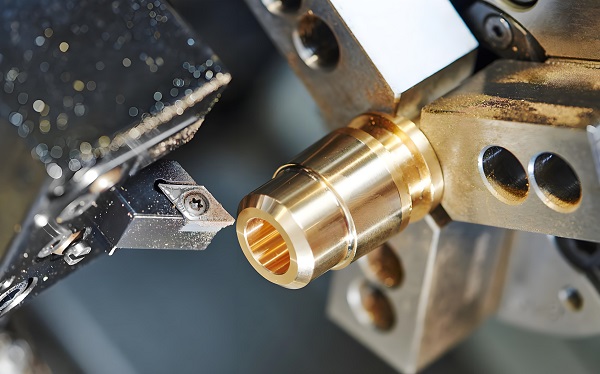

3. Core Component Processing for Electric Drive Systems

- Motor Rotor Shaft: Dynamic balance accuracy controlled within 0.5g·mm, surface roughness Ra ≤ 0.4μm, meeting operational requirements for high-speed motors above 20,000 rpm

- Motor Housing: Internal integration of complex oil/water cooling circulation channels, deep hole machining accuracy ±0.01mm, coaxiality ≤ 0.005mm

- Planetary Gear Assembly: Achieving ISO 1328-1 Grade 4-5 accuracy, with some reaching Grade 2, meeting high reliability requirements for transmission systems

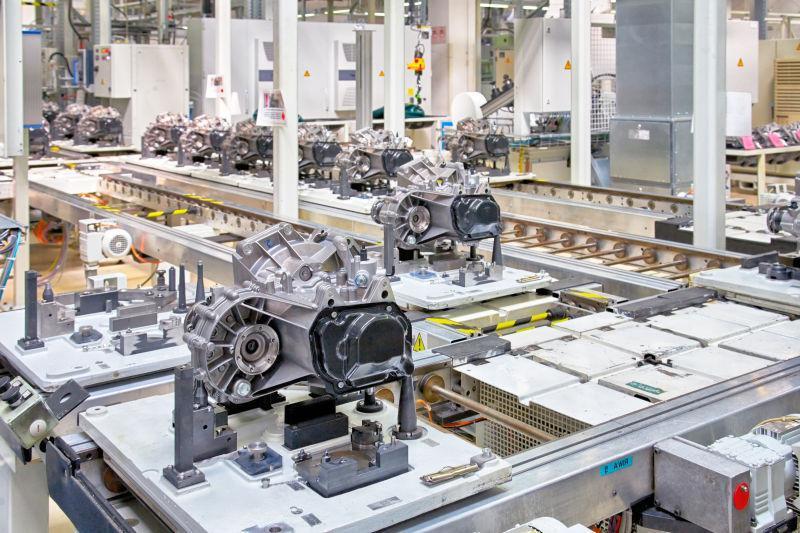

4. Intelligent Processing System

- MES System Integration: Equipment connectivity rate reaching 82%, real-time yield monitoring coverage 91%, complying with IATF 16949 process approach requirements

- Digital Twin Technology: New product trial production cycle reduced by 28%, yield rate improved to over 98.6%, based on VDA 6.3 process audit standards

- AI Quality Inspection: Inspection efficiency improved by over 5 times, full-size automatic collection and SPC analysis, meeting IATF 16949 continuous improvement requirements

Service Areas: Covering the Entire Automotive Industry Chain

Powertrain Components

- Motor housing and end cover (complying with ISO 230-2 accuracy standard)

- Motor rotor shaft (meeting ASTM balance requirements)

- Reducer gear assembly (achieving ISO 1328-1 accuracy grade)

- Inverter housing (complying with IP6K9K protection rating)

- Battery tray and casing (meeting lightweight and strength requirements)

Chassis System Components

- Aluminum alloy steering knuckle (ASTM B438 powder metallurgy standard)

- Control arm (ISO 9001 quality system guarantee)

- Shock absorber bracket (IATF 16949 process control)

- Subframe (VDA 6.1 audit standard)

- Brake system components (meeting safety-critical part requirements)

Thermal Management System Components

- Battery cooling plate (leakage rate ≤ 0.1g/year, complying with ASTM sealing standard)

- Refrigerant line connector (meeting high-voltage system requirements)

- Electronic expansion valve body (precision machining accuracy ±0.005mm)

- Radiator microchannel structure (maximizing heat dissipation area design)

Intelligent Driving System Components

- LiDAR metal bracket (dimensional tolerance ±5μm, geometric tolerance ≤ 0.01mm)

- Millimeter-wave radar housing (electromagnetic shielding effectiveness ≥ 80dB)

- Sensor mounting base (high-precision positioning requirements)

- Autonomous driving actuator (high reliability requirements)

Typical Case Study: In-depth Cooperation with New Energy Vehicle Manufacturers

- Material: High-strength alloy steel (complying with ASTM A370 mechanical property testing standard)

- Diameter: Φ30mm, roundness ≤ 0.002mm (ISO 230-2 standard)

- Length: 250mm, straightness ≤ 0.005mm

- Dynamic balance accuracy: ≤ 0.5g·mm (ASTM balance standard)

- Surface roughness: Ra ≤ 0.4μm (ISO surface roughness standard)

- Production volume: 100,000 pieces/year, PPM ≤ 10 (IATF 16949 quality target)

- Material Selection: Using high-strength alloy steel compliant with ASTM standards, quenched and tempered through VDA 6.4 certified heat treatment furnace

- Processing Technology: 5-axis turn-mill compound machining center equipped with online dynamic balance detection system, complying with ISO 230-2 testing standards

- Precision Control: Using German Heidenhain linear scales, positioning accuracy 0.001mm, repeatability 0.0005mm

- Quality Inspection: CMM, roundness tester, roughness tester and other inspection equipment, implementing SPC statistical process control

Quality System: Strict Automotive Industry Standards

IATF 16949:2016 Certification

- Five Core Tools: APQP, FMEA, MSA, SPC, PPAP

- Process Approach: Using turtle diagrams for process definition and management

- Continuous Improvement: PDCA cycle-based continuous improvement mechanism

- Customer Orientation: Customer satisfaction as the ultimate goal

VDA Series Standards

- VDA 6.1: Quality management system audit, ensuring system integrity

- VDA 6.3: Process audit, ensuring production process stability

- VDA 6.5: Product audit, ensuring final product quality

- VDA 4.2: FMEA failure mode and effects analysis

ISO 9001:2015 Certification

- Risk Management: Risk-based thinking approach

- Leadership: Top management’s quality commitment

- Resource Management: Ensuring adequate human and equipment resources

- Performance Evaluation: Regular internal audits and management reviews

Full-process Quality Control

- 100% Inspection: Each batch undergoes CMM, X-ray tomography and other inspections

- Traceability: Complete data chain of material composition, heat treatment curves, and key process parameters

- Continuous Improvement: Data analysis-based continuous improvement mechanism

- Customer-specific Requirements: Meeting exclusive quality agreement requirements of major OEMs

Comparative Advantages: Why Choose Us?

Technical Advantage Comparison

|

Comparison Item

|

Industry Average

|

Our Level

|

Advantage Description

|

|

Positioning Accuracy

|

±0.01mm

|

±0.005mm

|

Exceeds ISO 230-2 standard requirements

|

|

Repeatability

|

±0.005mm

|

±0.002mm

|

Reaching international advanced level

|

|

Processing Efficiency

|

Standard

|

40% improvement

|

One-time forming with 5-axis machining

|

|

Product Qualification Rate

|

95%

|

99.5%

|

Strict quality control system

|

|

Delivery Cycle

|

15-20 days

|

7-10 days

|

Intelligent production management

|

Certification Advantages

- International Certifications: IATF 16949, ISO 9001, VDA 6.x series

- Customer Recognition: Qualified supplier for multiple renowned automotive manufacturers

- Technical Capability: 26 years of professional experience, stable technical team

- Equipment Advantage: Imported high-end equipment with high precision and stability

Service Advantages

- Rapid Response: Quotation within 24 hours, samples within 72 hours

- Technical Support: Professional engineering team providing technical consultation

- Customization Capability: Customized development according to customer requirements

- After-sales Service: Comprehensive after-sales service system

Future Outlook: Growing Together with the Automotive Industry

- Technology Upgrade: Moving towards higher performance, lighter weight, and higher integration

- Market Opportunities: The automotive CNC machining market is expected to exceed RMB 85 billion by 2025

- Domestic Substitution: Local enterprises’ share in global Tier 2+ supply systems will increase from 21% to 35%

- Integrated Die Casting Post-processing Technology: Meeting precision machining requirements for large structural parts

- SiC Power Module Heat Sink Processing: Adapting to 800V high-voltage system development trends

- Carbon Fiber Composite Material Processing: Further promoting automotive lightweighting

- More Intelligent Production System: Achieving Industry 4.0 intelligent manufacturing

Conclusion: Looking Forward to Technical Dialogue with You

- Visit our website: https://www.xmgoldcattle.com/