1. Problem Analysis

1.1 Tool Failure Mechanisms

- Catastrophic breakage: Sudden fracture due to excessive cutting forces

- Fatigue failure: Progressive damage from repeated stress cycles

- Thermal failure: Overheating causing material softening or cracking

- Chipping: Small fragments breaking off from cutting edges

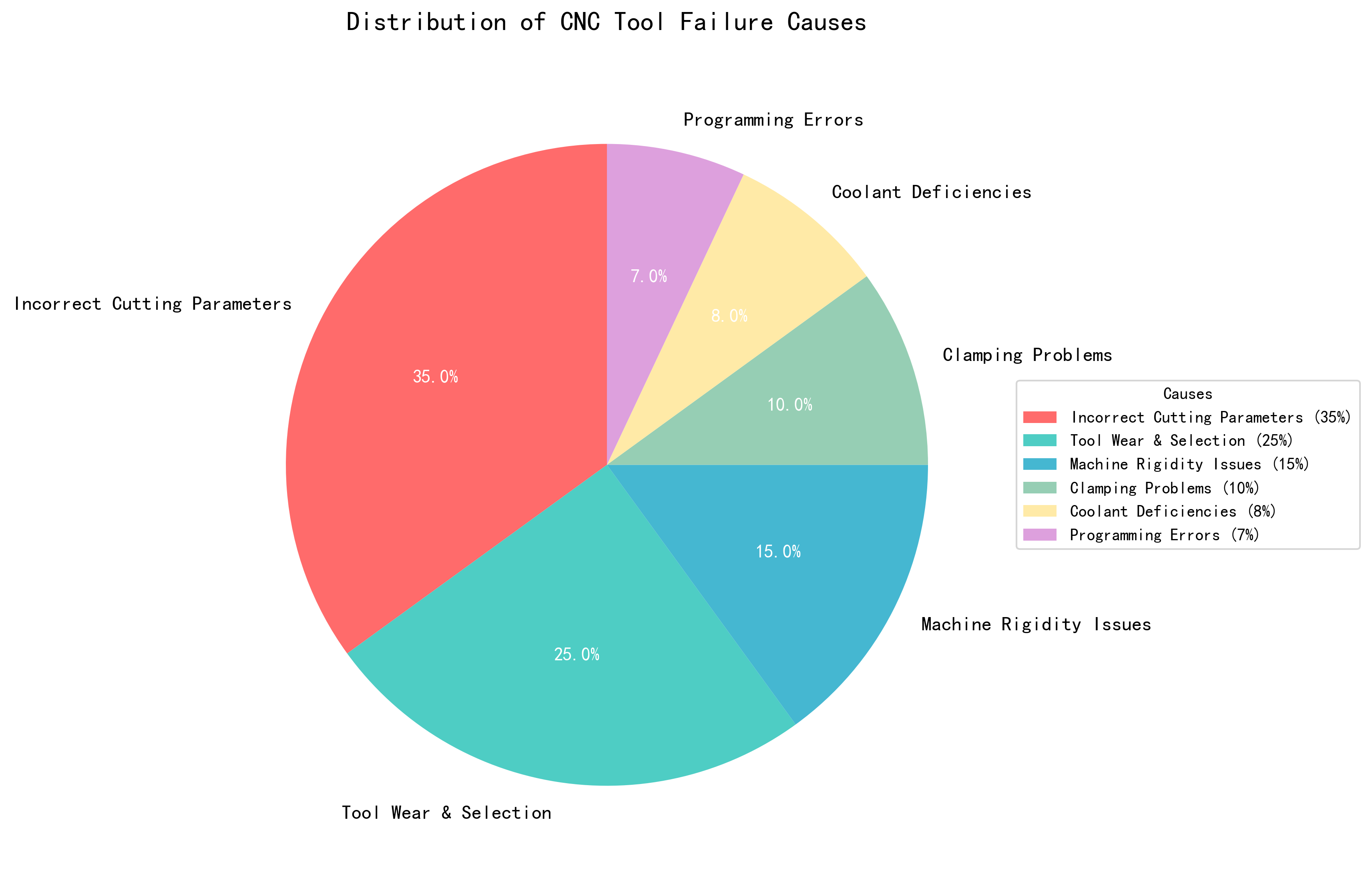

1.2 Root Cause Distribution

- Incorrect Parameters (35%): Most significant factor affecting tool integrity

- Tool Wear & Selection (25%): Material mismatch and wear issues

- Machine Rigidity (15%): Structural stability problems

- Clamping Issues (10%): Improper tool/workpiece holding

- Coolant Deficiencies (8%): Inadequate cooling/lubrication

- Programming Errors (7%): Path planning and strategy issues

2. Performance Analysis

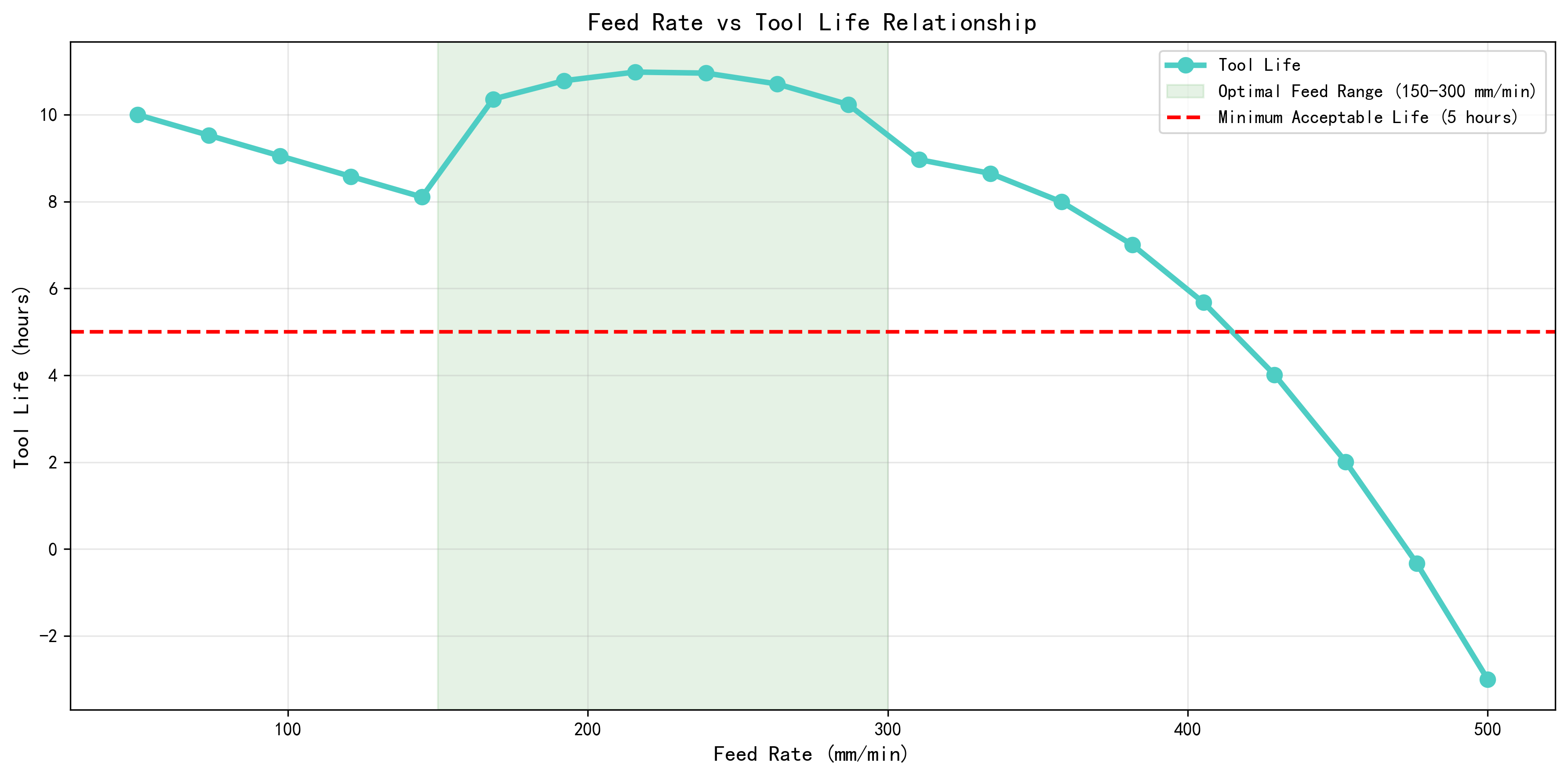

2.1 Feed Rate vs Tool Life Relationship

- Optimal Feed Range (150-300 mm/min): Maximizes tool life (8-11 hours)

- Low Feed Performance: Reduced productivity despite longer tool life

- High Feed Performance: Dramatic tool life reduction (>300 mm/min)

- Acceptable Limit: Tool life drops below 5 hours outside optimal range

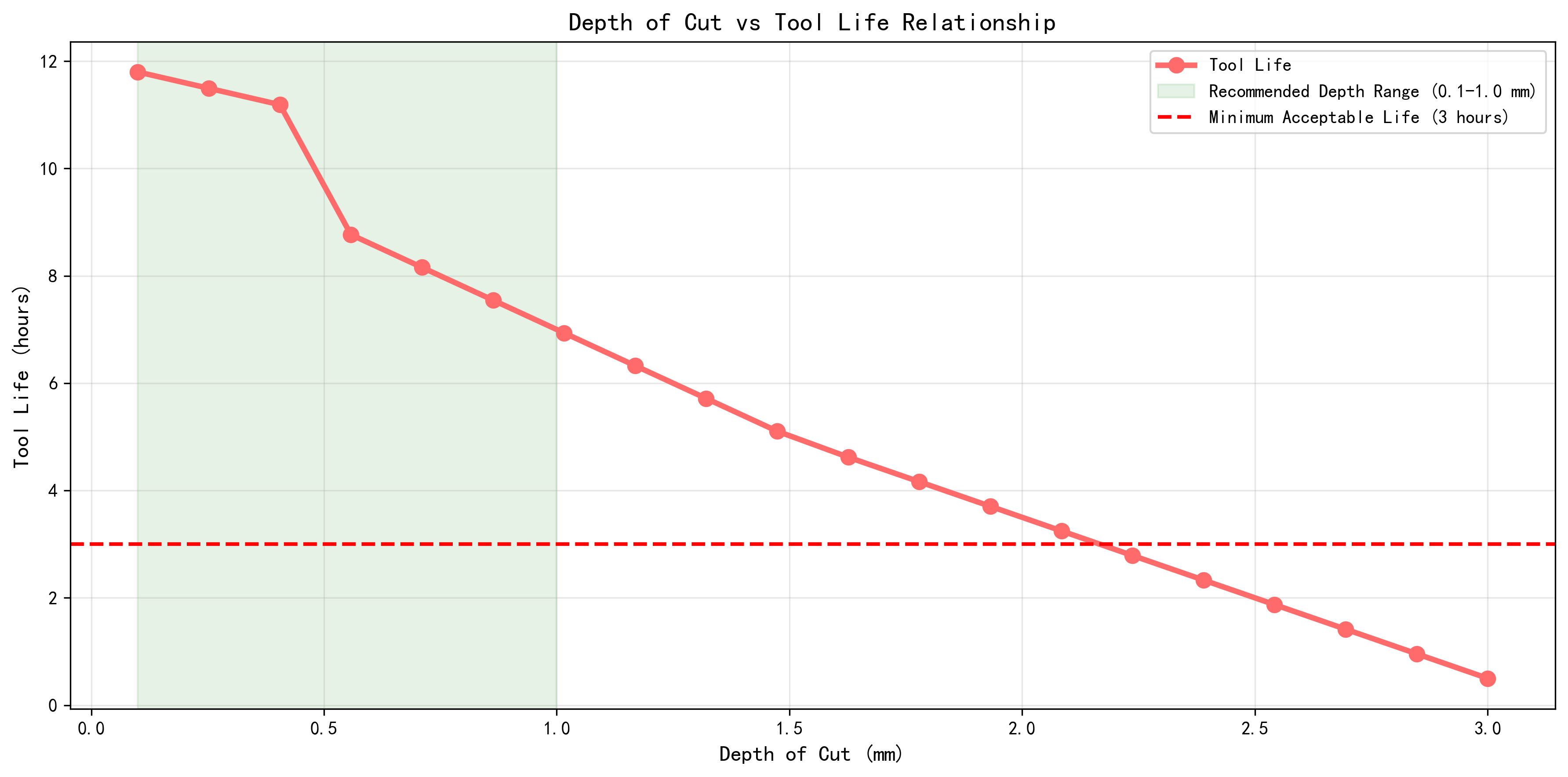

2.2 Depth of Cut vs Tool Life Relationship

- Recommended Depth Range (0.1-1.0 mm): Balances productivity and tool life

- Medium Depth Performance: Gradual tool life reduction (1.0-1.5 mm)

- Deep Cut Performance: Accelerated failure (>1.5 mm depth)

- Critical Threshold: Tool life drops below 3 hours at >2.0 mm depth

3. Solutions and Recommendations

3.1 Comprehensive Solution Framework

|

Root Cause

|

Recommended Solutions

|

Priority

|

Expected Improvement

|

|

Incorrect Parameters

|

Implement parameter optimization based on material

|

High

|

40% reduction in failures

|

|

Tool Wear & Selection

|

Use coated carbide tools, implement life tracking

|

High

|

35% improvement in tool life

|

|

Machine Rigidity

|

Upgrade foundations, use vibration damping

|

Medium

|

25% reduction in vibration

|

|

Clamping Issues

|

Implement hydraulic clamping, optimize fixtures

|

High

|

30% improvement in stability

|

|

Coolant Deficiencies

|

Upgrade to high-pressure coolant systems

|

Medium

|

20% thermal protection

|

|

Programming Errors

|

Use CAM simulation, optimize tool paths

|

Medium

|

15% reduction in path issues

|

3.2 Implementation Roadmap

Phase 1: Immediate Actions (1 week)

- Implement parameter optimization based on material type

- Upgrade to high-quality coated cutting tools

- Improve coolant delivery systems

Phase 2: Short-term Improvements (1-2 months)

- Install hydraulic clamping systems

- Implement tool life monitoring systems

- Develop material-specific machining databases

Phase 3: Long-term Solutions (3-6 months)

- Invest in machine rigidity improvements

- Implement predictive maintenance algorithms

- Develop operator training programs

4. Expected Outcomes

|

Metric

|

Current

|

Target

|

Improvement

|

|

Tool Failure Rate

|

15%

|

3%

|

80% reduction

|

|

Average Tool Life

|

4 hours

|

8 hours

|

100% improvement

|

|

Production Downtime

|

8%

|

2%

|

75% reduction

|

|

Tool Cost per Part

|

$2.50

|

$1.25

|

50% reduction

|

|

Overall Equipment Efficiency

|

70%

|

85%

|

21% increase

|

5. Conclusion

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.

The research results and technical insights shared herein are based on the author’s professional experience and experimental observations. The author and the affiliated institution shall not be liable for any direct, indirect, or consequential damages (including but not limited to equipment damage, product quality issues, or production losses) arising from the improper use of the information provided in this paper.