CNC Turned Parts Manufacturer – Precision Turning Solutions by Xiamen Goldcattle (26 Years Expertise)

In 2025, a leading EV manufacturer came to us with a critical issue: their motor shafts were vibrating excessively, reducing battery efficiency by 4%. Using our 4-axis live tooling lathes and specialized toolpath optimization, we cut vibration by 50% – and they immediately placed an annual order.

Our Swiss-type CNC lathes achieve ±0.005mm tolerance for micro-precision components

What Is a CNC Turned Parts Manufacturer?

A CNC turned parts manufacturer specializes in producing rotational components using Computer Numerical Control (CNC) turning technology. Unlike generic part suppliers, we don’t just sell off-the-shelf items—we create custom, precision-engineered parts tailored to your exact specifications.

Whether you need a 0.5mm micro-pin for electronics or a 1-meter shaft for industrial machinery, we use CNC lathes to shape materials with unmatched accuracy, consistency, and efficiency.

The core of our work lies in subtractive manufacturing: spinning a workpiece while stationary cutting tools remove material to create cylindrical, conical, or complex shapes. This process excels at producing parts with tight tolerances (as low as ±0.001mm), smooth surface finishes, and symmetrical features—critical for applications where fit and function can’t be compromised.

“We’ve seen it all in 26 years of CNC turning. What sets us apart is our ability to solve problems that others can’t—like the medical device client who needed a 0.3mm diameter part with a 0.005mm wall thickness. Our Swiss-type machines and specialized tooling made it possible.”

— Goldcattle Technical Team

The Technology That Defines Our Craft

1. Machinery: From Basic to Cutting-Edge

Swiss-type CNC Lathes

±0.005mm tolerance for micro-components

Micro-Precision Parts

0.3mm diameter with tight tolerances

A reliable CNC turned parts manufacturer invests in equipment that meets diverse needs. Goldcattle’s workshop features a range of CNC turning centers:

- 2-axis CNC lathes: Workhorses for simple cylindrical parts, handling diameters up to 300mm with ±0.002mm tolerance—ideal for bushings and spacers.

- 4-axis CNC lathes: Equipped with live tooling and a rotational C-axis, these machines mill flats, drill holes, and cut threads while turning, eliminating secondary operations for parts like gear shafts.

- Swiss-type CNC lathes: The gold standard for small, complex components. With guide bushings that stabilize long, thin workpieces, they achieve ±0.0005mm tolerance for parts as tiny as 0.3mm in diameter—perfect for medical needles and microelectronics.

Real-World Impact

Our 4-axis lathes reduced production time by 35% for a client needing valve bodies with integrated slots, combining turning and milling in one setup. This eliminated the need for secondary operations and cut their lead time from 4 weeks to 2.5 weeks.

2. Materials: Matching Performance to Purpose

A top CNC turned parts manufacturer doesn’t just machine materials—we select them strategically. Goldcattle works with a spectrum of options to meet your project’s demands:

Stainless Steel (304/316)

Corrosion-resistant and strong (tensile strength up to 620 MPa)

Used in marine hardware and food processing equipment where hygiene matters.

Aluminum (6061/7075)

Lightweight (2.7 g/cm³) with excellent machinability

Ideal for aerospace fasteners and EV motor shafts.

Brass (C36000)

High conductivity and low friction (coefficient 0.2)

Perfect for electrical connectors and plumbing fittings.

Titanium (Ti-6Al-4V)

Biocompatible and heat-resistant

Essential for orthopedic implants and jet engine components.

Material Expertise in Action

We had a client who was using 316 stainless steel for a marine application, but they were experiencing premature wear. Our materials team recommended upgrading to a duplex stainless steel with higher corrosion resistance and hardness. The result? Their parts now last 3 times longer in saltwater environments.

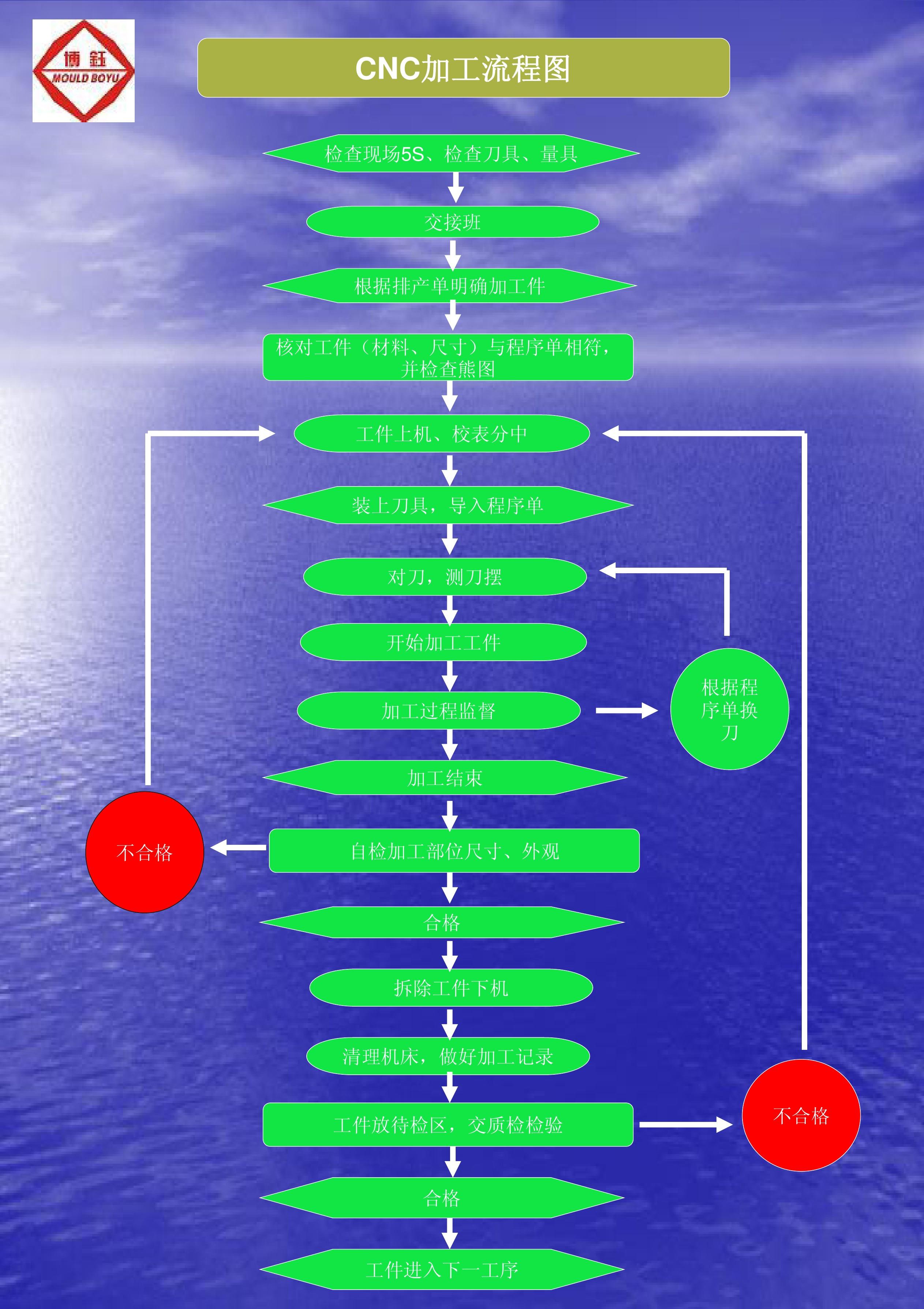

3. Our Process: From Design to Delivery

Our rigorous 6-step workflow ensures consistent quality for every part

A reputable CNC turned parts manufacturer follows a rigorous workflow to ensure quality:

Design & DFM Collaboration

We review your CAD files to provide Design for Manufacturability (DFM) feedback. For example, we might suggest adding a 0.2mm radius to a sharp edge to prevent tool wear and improve part strength.

Material Inspection

Raw bar stock undergoes ultrasonic or eddy current testing to catch defects—critical for high-stress parts like aircraft landing gear pins.

CNC Programming

Engineers convert designs into machine code, optimizing spindle speeds (3,000–12,000 RPM for metals) and tool paths to minimize waste and maximize precision.

Precision Turning

Workpieces are clamped into CNC lathes, where carbide or diamond tools shape them to exact dimensions. Swiss-type machines excel here, maintaining stability even for parts with high length-to-diameter ratios.

Quality Control

Every part is inspected using micrometers, surface roughness testers (Ra as low as 0.02μm), and CMMs. Critical medical parts undergo 100% inspection to meet ISO 13485 standards.

Finishing

Services like passivation (for stainless steel), anodizing (for aluminum), or electropolishing (for medical parts) enhance durability, aesthetics, and functionality.

Process Excellence in Practice

A medical device client came to us with a part that was failing fatigue testing. Through our DFM analysis, we identified a stress concentration point that was causing cracks. By redesigning the part with a smoother transition and using our precision turning process, we eliminated the failure mode and helped them pass their regulatory testing on the first attempt.

Industries We Serve: Where Precision Matters Most

Common Challenges in CNC Turning & How We Solve Them

After 26 years in the business, we’ve encountered and solved just about every challenge in CNC turning. Here are some of the most common issues and our proven solutions:

Thin-Wall Deformation

Challenge: Parts with wall thickness less than 0.5mm often deform during machining due to cutting forces and heat.

Our Solution: We use specialized tooling with high positive rake angles, reduced cutting forces, and cryogenic cooling. For one medical client, this reduced deformation from 0.05mm to 0.005mm on their 0.3mm wall thickness parts.

Tool Marks & Surface Finish

Challenge: Achieving Ra < 0.2μm surface finish without extensive polishing.

Our Solution: We use diamond-coated tools, optimized cutting parameters, and in-process finishing techniques. For an optical component client, we achieved Ra 0.08μm directly from the machine, eliminating the need for secondary polishing.

Material Cracking

Challenge: Brittle materials like titanium and high-temperature alloys often crack during machining.

Our Solution: We use vibration damping systems, specialized cutting fluids, and optimized tool paths. For an aerospace client working with Inconel 718, we reduced cracking from 15% to 0% using these techniques.

Facing a CNC Turning Challenge?

Send us your part drawing and we’ll provide a free analysis of potential challenges and our recommended solutions.

Why Choose Goldcattle as Your CNC Turned Parts Manufacturer?

Years of Expertise

We’ve solved complex turning challenges for 1,000+ clients, from startups to Fortune 500 companies.

Quality Certifications

ISO 9001, ISO 13485, and AS9100D certifications mean every part meets global standards for reliability.

Flexible Production

Whether you need 10 prototypes or 100,000 production parts, we scale with lead times as fast as 5 days for urgent orders.

End-to-End Support

From design advice to post-production finishing, we handle every step in-house—no outsourcing, no surprises.

Trusted by Industry Leaders

Served 1,000+ Clients Worldwide

From small startups to Fortune 500 companies, across 30+ countries

FAQs About CNC Turned Parts Manufacturers

Ready to Partner with a Trusted CNC Turned Parts Manufacturer?

Your project deserves more than just a supplier—it needs a partner who understands precision, reliability, and your unique goals. At Goldcattle, we combine advanced technology with decades of experience to deliver CNC turned parts that fit perfectly, perform reliably, and stand the test of time.

Get Your Free Precision Turning Quote in 24 Hours

- • Free DFM feedback on your design

- • Detailed cost breakdown

- • Lead time estimate

- • Material recommendations

- • Quality assurance plan

- • 24-hour response guarantee

With 26 years of specialized experience, end-to-end in-house production, and dual medical/aerospace certifications, Goldcattle is your trusted partner for precision CNC turned parts. Let’s turn your design into a component that powers the future.