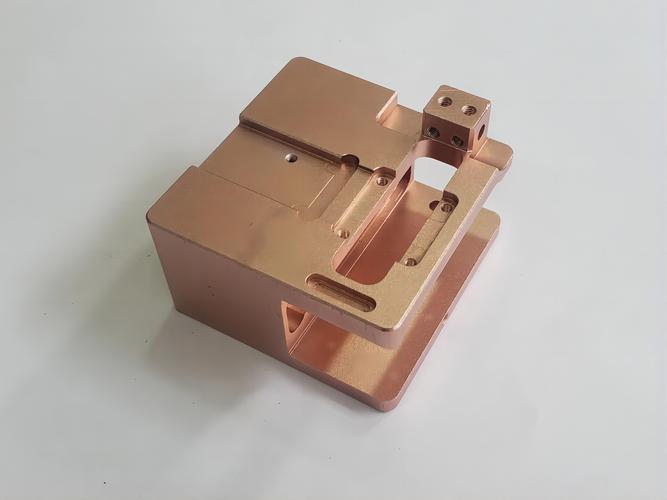

Turned parts refer to mechanical parts formed by rotating workpieces on a lathe, covering revolving surfaces such as internal and external cylindrical surfaces, conical surfaces, and threads. Commonly used materials include aluminum (EN AW – 6061), steel (C45), stainless steel (1.4301), copper (E – Cu57), titanium (grades 2 and 5), and polymers (PEEK). Surface treatments include spraying, polishing, pearlescent treatment, and heat treatment.

I. Introduction to CNC/Turning Machining

CNC turning machining is a computer – controlled processing technology. By rotating a solid workpiece, a fixed cutting tool removes excess material from the workpiece to form the final shape of the part. All operations are automatically executed according to the CAD model uploaded to the CNC lathe.

Computer numerical control (CNC) milling is generally a metal manufacturing process; however, plastics can also be processed. CNC milling uses a computer to control the cutting tool. Then, this cutting tool cuts materials from the workpiece to produce the desired shape/model.

The cutting tool is the main working part of the CNC milling machine and can move on three or more axes. Usually, the workpiece remains stationary. However, modern CNC milling machines can swing or rotate the workpiece to obtain a better cutting angle. This function can also speed up the process because when milling complex designs, machinists do not need to re – orient the workpiece.

CNC milling is a relatively simple process, which is why it is the most widely used production process in the metal industry. Everything from prototypes to final designs is usually completed in a CNC milling machine.

II. CNC/Turning Machining Services

All precision CNC – turned parts of Yingmeng need to go through strict quality control and testing to ensure they meet the highest standards and requirements. They can adapt to extreme conditions such as high temperature and high pressure in harsh environments and maintain excellent performance and reliability. Therefore, our products are widely used in products that require high – reliability components, such as aerospace, medical devices, energy, and automated control. These include implants in medical devices and key components in energy equipment. As the terminal of a capacitive coolant level switch, the copper – turned parts produced by Yingmeng can be used normally in a high – temperature environment of 125°C and a low – temperature environment of – 40°C.

III. The Synergy between CNC Milling and Turning

Integrating milling and turning in a single production setup has significant advantages:

Integrated Processing of Complex Parts: By combining milling (suitable for cavities and flat surfaces) with turning (suitable for cylindrical parts and threads), the number of clamping operations can be minimized. This integration not only improves accuracy (achieving tolerances as low as ±0.02 mm) but also reduces the risk of misalignment.

Maximizing Material Utilization: The optimized tool paths inherent in the integrated process can reduce material waste by 15 – 25%. This efficiency is particularly beneficial for industries that focus on sustainable practices and highly cost – effective production.

Shortening the Production Cycle: Multiple processes can be completed in one clamping, and the delivery time can be shortened by 30 – 50%. This dual – method directly impacts the delivery time, making CNC milling and turning services a cost – effective solution for large – volume orders.

IV. Technical Advantages of Milling – Turning Integration

The technical advantages of the integrated milling and turning method are driven by state – of – the – art equipment and innovative process management:

Equipment and Processes: Modern milling – turning centers (such as the Mazak INTEGREX series) can support large workpieces with a maximum size of Ø500 mm × 1,000 mm. These machines combine high – speed milling and precise turning in one setup, reducing the need for multiple clamping operations.

Intelligent Tool Management: The automatic tool – changing system provides more than 30 tool positions, minimizing downtime. This function is particularly important for maintaining continuous production without sacrificing accuracy.

Precision Control: On – line measurement systems can compensate for thermal deformation in real – time, ensuring that tolerances remain within ≤±0.01 mm. In addition, the surface finish can be optimized to Ra 0.8 μm during milling and Ra 0.4 μm during turning, thus providing high – quality parts.

V. Processing Steps for Turned Parts

Before Operation

Before starting work, use protective equipment as required, tuck in your sleeves, do not wear scarves or gloves. Female workers should tuck their hair into their hats. Operators must stand on the foot pedal.

Conduct a strict inspection of bolts at all parts, travel limits, signals, safety protection (insurance) devices, mechanical transmission parts, electrical parts, and lubrication points. Only after ensuring reliability can the machine be started.

The lighting for various machine tools should use safe voltage, and the voltage should not exceed 36 volts.

During Operation

Workpieces, fixtures, tools, and workpieces must be clamped firmly. For all types of machine tools, after starting, perform a low – speed idle run first. After everything is normal, formal operation can begin.

Do not place tools and other items on the machine tool guideways and workbench. Do not remove iron filings by hand; use special tools for cleaning.

Observe the surrounding conditions before starting the machine. After the machine starts, stand in a safe position to avoid the moving parts of the machine and flying iron filings.

During the operation of various machine tools, do not adjust the speed – changing mechanism or travel. Do not touch the transmission parts, moving workpieces, tools, and other working surfaces during processing with your hands. Do not measure any dimensions during operation. It is prohibited to pass or pick up tools and other items across the transmission parts of the machine.

If abnormal noises are found, stop the machine for inspection immediately. Do not operate it forcibly or when it is malfunctioning. Do not overload the machine.

During the processing of each part, strictly follow the process discipline, read the drawings clearly, understand the control points, roughness, and technical requirements of relevant parts, and determine the processing procedures for the workpiece.

Stop the machine when adjusting the machine speed, travel, clamping the workpiece and tool, and wiping the machine. Do not leave the work post when the machine is running. If you need to leave for some reason, stop the machine and cut off the power.

After Operation

Stack the raw materials to be processed, finished products, semi – finished products, and waste materials in the designated places. All tools and cutters must be kept complete and in good condition.

After the operation, cut off the power supply, remove the tool, place all handles in the neutral position, and lock the switch box.

Clean the equipment, sweep up the iron filings, and lubricate the guideways to prevent rust.

The processing regulations for turned parts are one of the process documents that specify the machining process and operation methods of parts. Under specific production conditions, a relatively reasonable process and operation method are written into a process document in a specified form. After approval, it is used to guide production. The processing process regulations for turned parts generally include the following contents: the process route of workpiece processing, the specific content of each process and the equipment and process equipment used, the inspection items and inspection methods of the workpiece, cutting parameters, and time quota.