- Overview of CNC Wood Processing

- Common CNC Processable Wood Types

- Wood Properties and Processing Considerations

- CNC Woodworking Equipment

- Processing Techniques and Parameters

- Application Areas

- Technical Advantages and Challenges

Overview of CNC Wood Processing

Basic Principles

- Design Modeling: Create 3D models using CAD software

- Path Generation: Generate processing paths through CAM software

- Equipment Setup: Set processing parameters according to wood characteristics

- Automatic Processing: CNC equipment completes processing automatically according to the program

- Quality Inspection: Verify processing precision and quality

Common CNC Processable Wood Types

Hardwoods

- Oak: Hardness 1360, beautiful grain, strong corrosion resistance

- Maple: Hardness 1450, hard texture, fine grain

- Walnut: Hardness 1010, elegant color, good processing performance

- Cherry: Hardness 950, beautiful color, suitable for fine carving

- Birch: Hardness 760, uniform texture, good stability

Softwoods

- Pine: Hardness 380-560, clear grain, good processing performance

- Cedar: Hardness 900, natural preservative, aromatic scent

- Fir: Hardness 600, light and soft texture, suitable for large-scale processing

- Spruce: Uniform texture, suitable for making musical instruments

Engineered Woods

- Plywood: Multi-layer veneer bonding, good stability

- Medium Density Fiberboard (MDF): Uniform density, suitable for fine carving

- Particleboard: Low cost, suitable for basic structures

- Oriented Strand Board (OSB): High strength, suitable for construction applications

Wood Properties and Processing Considerations

Key Property Parameters

|

Wood Type

|

Janka Hardness

|

Density (g/cm³)

|

Processing Difficulty

|

Main Applications

|

|

Oak

|

1360

|

0.75

|

Medium

|

Furniture, Flooring

|

|

Maple

|

1450

|

0.70

|

High

|

High-end Furniture, Musical Instruments

|

|

Walnut

|

1010

|

0.64

|

Medium

|

Decoration, Crafts

|

|

Pine

|

380-560

|

0.45

|

Low

|

Construction, Furniture

|

|

MDF

|

–

|

0.70

|

Low

|

Carving, Decoration

|

Processing Considerations

- High-density woods require greater cutting force

- Low-density woods can be processed at faster speeds

- Tool selection needs to be adjusted according to wood hardness

- Ideal processing moisture content: 8-12%

- Excessively high moisture content reduces processing precision

- Excessively low moisture content It is prone to cracking.

- Processing along the grain is smoother

- Cross-grain processing requires reduced feed rate

- Special attention to tool wear in knot areas

CNC Woodworking Equipment

Equipment Types

- Suitable for flat engraving and 3D modeling

- Equipped with automatic tool change system

- Working area ranges from desktop to industrial grade

- Multi-axis linkage, complex curved surface processing

- Automatic loading/unloading system

- High-precision positioning system

- Non-contact processing, extremely high precision

- Suitable for fine patterns and text engraving

- Small heat-affected zone

Tool Selection

- Low cost, suitable for softwood processing

- General wear resistance, frequent replacement needed

- High hardness, good wear resistance

- Suitable for hardwoods and engineered woods

- Long service life

- Extremely high hardness, suitable for special materials

- Higher cost, used for high-precision processing

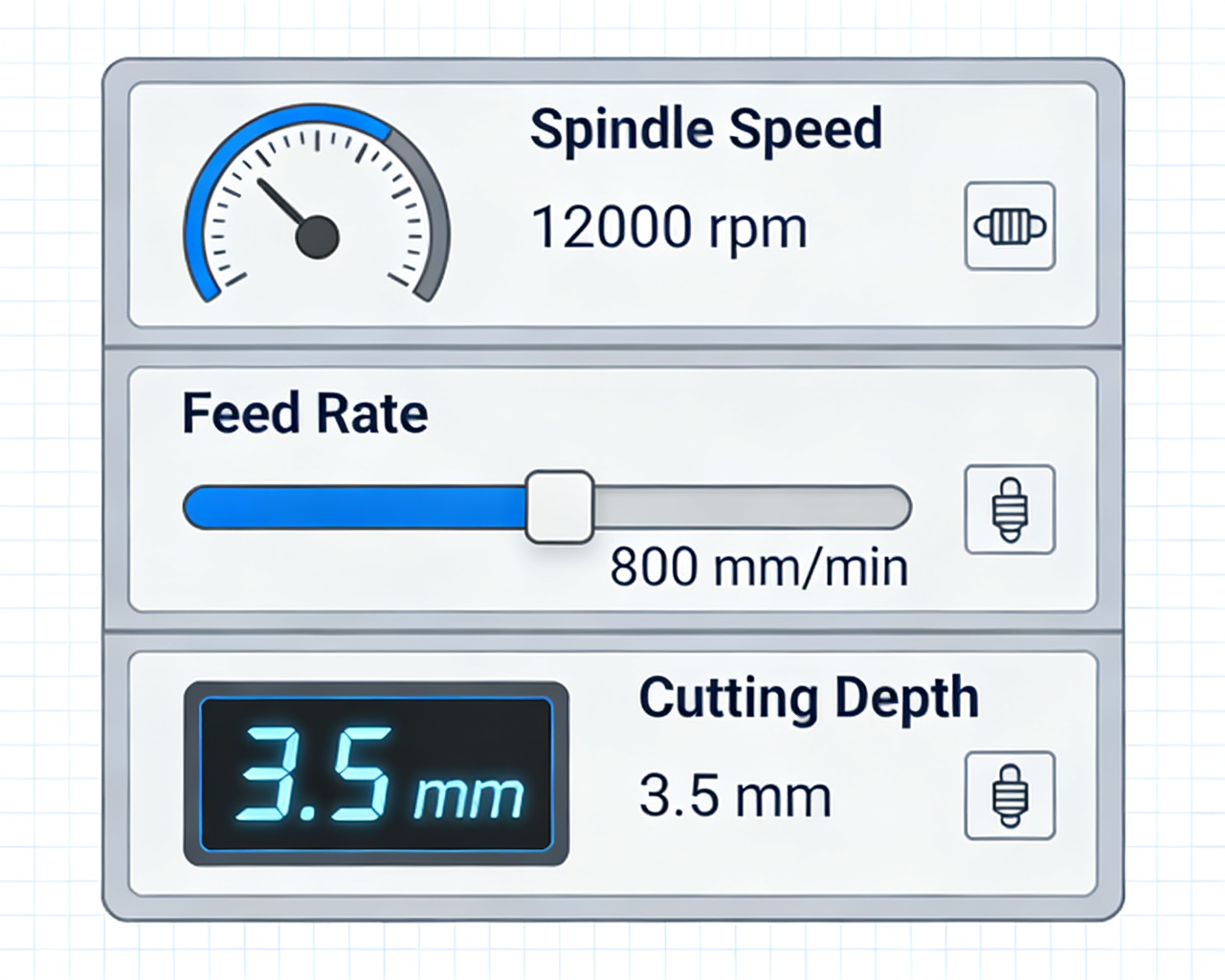

Processing Techniques and Parameters

Processing Parameter Settings

- Softwoods: 10-15 m/min

- Hardwoods: 5-10 m/min

- Engineered woods: 8-12 m/min

- Along grain: 8-12 m/min

- Cross grain: 4-6 m/min

- Engraving processing: 2-5 m/min

- Softwoods: 10,000-15,000 rpm

- Hardwoods: 8,000-12,000 rpm

- Fine processing: 15,000-24,000 rpm

Process Optimization

- Reduce empty travel time

- Optimize tool path sequence

- Adopt layered processing strategy

- Compressed air cooling

- Cutting fluid cooling (suitable for hardwoods)

- Dust removal system to prevent wood chip accumulation

Application Areas

Furniture Manufacturing

- Personalized design implementation

- Complex shape processing

- Batch production consistency

- Precise dimension control

- Complex joining structures

- Surface decoration engraving

Architectural Decoration

- Wall decorative panels

- Ceiling modeling

- Decorative moldings

- Wooden sculptures

- Landscape features

- Outdoor furniture

Craft Production

- Fine carving techniques

- Complex pattern implementation

- Personalized customization

- High-precision soundboard processing

- Complex curved surface modeling

- Sound quality optimization design

Technical Advantages and Challenges

Main Advantages

- Sub-millimeter precision control

- Accurate implementation of complex shapes

- Good consistency in batch production

- Automated processing flow

- 24-hour continuous production

- Significant reduction in labor costs

- Easy implementation of complex shapes

- Strong personalized customization capability

- Rapid prototype development

Challenges

- High-end CNC equipment is expensive

- Relatively high maintenance costs

- Technical personnel training requirements

- Natural wood properties are unstable

- Moisture content changes affect precision

- Complex knot and defect handling

- Wood chip dust treatment

- Noise control

- Adhesive environmental requirements

Development Trends

Intelligent Upgrading

- Automatic identification of wood properties

- Intelligent parameter optimization

- Predictive maintenance

- Remote monitoring and management

- Data collection and analysis

- Equipment networking collaboration

Green Manufacturing

- Recycled wood utilization

- Environmentally friendly adhesives

- Low-carbon processing techniques

- High-efficiency dust removal systems

- Noise control technology

- Waste recycling and utilization