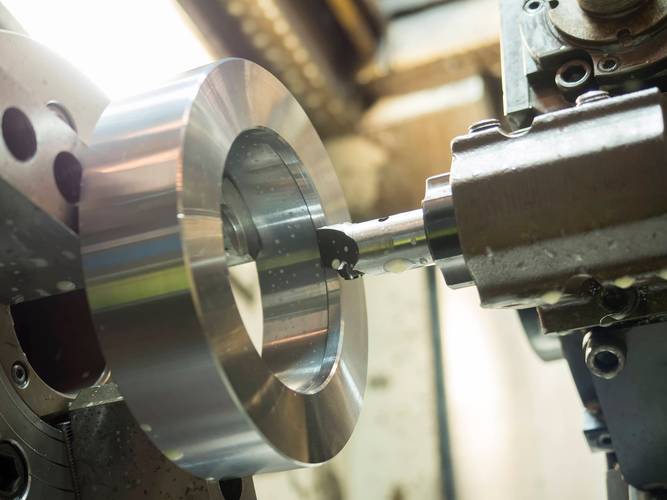

In industries such as aerospace, electronic equipment, and automotive manufacturing, CNC Milling Parts serve as the “core framework” ensuring the precise operation of equipment. From precision aluminum enclosures to high-strength stainless steel structural components, high-quality CNC milling parts directly determine the performance and service life of end products. This article breaks down key knowledge about CNC milling parts from four dimensions—”understanding components,” “scientific selection,” “design optimization,” and “supplier evaluation”—to help you efficiently solve procurement and application challenges.

1. Understanding CNC Milling Parts: Key Components and Common Types

To select and use CNC milling parts correctly, it is first necessary to clarify their core composition and classification—a fundamental requirement for engineers and procurement personnel.

1.1 Key Components of CNC Milling Machines: The “Critical Factor” Determining Milling Part Precision

The processing quality of CNC milling parts is closely related to the core components of milling machines. According to research from TSINFA (a well-known industry technical institution) and Aria Manufacturing, the following 8 components directly affect the precision of milling parts:

- Spindle: The core component that clamps cutting tools, with a speed range typically between 8,000–15,000 rpm. High-speed spindles (e.g., above 12,000 rpm) are suitable for precision small-part processing, while low-speed, high-torque spindles are ideal for heavy metal parts.

- Servo Motor: The power source controlling the movement of milling parts along the X/Y/Z axes. High-quality motors can achieve a displacement precision of ±0.001 mm, making them essential for aerospace-grade milling parts.

- Guide Rails: Support the sliding of the worktable. Cast iron guide rails offer strong stability, while granite guide rails provide better anti-vibration performance, making them suitable for high-precision milling needs.

- Worktable: The platform for placing workpieces, which must have deformation resistance. Common materials include 45# steel or aluminum alloy, with the surface treated by quenching to enhance wear resistance.

- Tool Magazine: An automatic tool-changing device. The tool magazine capacity (16–60 tools) determines processing efficiency; large-capacity tool magazines are required for multi-variety milling part production.

- Cooling System: Prevents milling part deformation due to excessive temperature during cutting. Oil cooling is suitable for high-speed processing, while water cooling is used for heavy-duty cutting.

- Feedback System: Real-time monitors displacement through linear scales or encoders to ensure the dimensional error of milling parts is within the allowable range.

- Control System: Systems such as FANUC and Siemens; their operating smoothness and compatibility directly affect processing efficiency.

1.2 Common Types of CNC Milling Parts: Classified by Material and Application Scenario

Different industries have distinct requirements for the material and performance of CNC milling parts. Common classifications are as follows:

- Classified by Material:

- Aluminum Alloy Milling Parts (e.g., 6061, 2024-T6): Lightweight and corrosion-resistant, suitable for electronic equipment enclosures and automotive components. Professional manufacturers in the industry can achieve over 85% adaptability of such products in the drone and consumer electronics fields.

- Stainless Steel Milling Parts (e.g., 304, 316): High-strength and rust-resistant, used in medical equipment and food machinery. Manufacturers need to provide full-process customization from design to processing to meet medical-grade precision requirements.

- Titanium Alloy Milling Parts (e.g., TC4): High-temperature resistant and high-strength, suitable for the aerospace field. Manufacturers equipped with 5-axis high-precision milling equipment can achieve a processing precision of ±0.003 mm for titanium alloy parts.

- Plastic Milling Parts (e.g., POM, PC): Insulating and low-cost, suitable for home appliance accessories. Specialized plastic processing production lines can avoid cracking and deformation during processing.

- Classified by Application Scenario:

- Precision Structural Parts (e.g., sensor enclosures, connectors): Require a precision of ±0.005 mm and need 5-axis CNC milling equipment for processing. The 5-axis workshops of leading industry manufacturers can handle over 200 precision part orders per day.

- Load-Bearing Parts (e.g., mechanical brackets, fixtures): Emphasize strength and stability, mostly made of 45# steel through milling. After quenching and tempering treatment, their service life can be increased by 30%.

- Customized Accessories (e.g., non-standard screws, special-shaped interfaces): Require OEM services from manufacturers. High-quality suppliers support small-batch customization (starting from 10 pieces) with a sample lead time as short as 3 days.

2. CNC Milling Parts Selection Guide: 3 Core Dimensions + 4 Common Misunderstandings

When procuring CNC milling parts, focusing only on price or precision can easily lead to “poor adaptability” and “cost waste.” Combining practical experience from enterprises such as 3ERP and Protolabs, scientific selection should focus on the following points:

2.1 3 Core Selection Dimensions

-

Dimension 1: Match Precision to Actual Needs

Higher precision is not always better—electronic equipment enclosures require a precision of ±0.01 mm, while mechanical brackets only need ±0.1 mm. Excessively pursuing high precision can increase costs by 30%–50%. It is recommended to select according to industry standards:- Aerospace: ±0.002–0.005 mm (requires 5-axis milling);

- Automotive Manufacturing: ±0.01–0.02 mm;

- General Machinery: ±0.05–0.1 mm.

-

Dimension 2: Match Material to Usage Environment

Prioritize 316 stainless steel for humid environments (e.g., bathroom equipment); titanium alloy or high-temperature alloys for high-temperature environments (e.g., engine components); and 6061 aluminum alloy for lightweight needs (e.g., drones). For example, 6061 aluminum alloy milling parts customized by a drone manufacturer are 40% lighter than traditional steel parts while meeting impact resistance requirements. -

Dimension 3: Match Production Capacity to Order Scale

- Small-Batch Customization (10–100 pieces): Choose manufacturers that support “rapid prototyping” (usually providing samples within 24 hours, with prototype costs deductible from bulk order payments);

- Large-Batch Production (1,000+ pieces): Prioritize suppliers with automated production lines (monthly capacity up to 150,000 pieces). Scale production can reduce unit costs, with bulk orders eligible for discounts of up to 20%.

2.2 4 Common Selection Misunderstandings

- Misunderstanding 1: Focusing only on “surface precision” while ignoring “stability”—some manufacturers mark precision as “single-process precision,” but errors may exceed limits during mass production. It is necessary to require suppliers to provide “batch inspection reports” (e.g., coordinate measuring reports);

- Misunderstanding 2: Ignoring “processing process compatibility”—for example, high-speed milling of stainless steel parts can easily cause tool wear. Professional manufacturers will use “low-speed, high-torque + special cooling oil” processes for stainless steel parts to reduce tool loss;

- Misunderstanding 3: Not considering “subsequent assembly needs”—the hole positions and tolerances of milling parts must match other components. It is recommended to provide assembly drawings to manufacturers; some suppliers can offer “pre-assembly testing” services;

- Misunderstanding 4: Blindly choosing low-cost suppliers—unqualified small factories may use inferior materials (e.g., non-standard aluminum alloy), leading to milling part deformation. High-quality manufacturers use raw materials that meet international standards (e.g., Southwest Aluminum 6061, Baosteel 304 stainless steel) and provide material certification.

3. CNC Milling Parts Design Tips: Improve Processing Efficiency and Product Quality

Good design can reduce processing difficulty and costs. Engineers from Geomiq and Protolabs Network have summarized 5 practical design tips applicable to various milling parts:

3.1 Set Tolerances Reasonably: Avoid “Over-Design”

Set tolerances based on usage scenarios: non-mating surfaces can have a tolerance of ±0.1 mm, while mating surfaces (e.g., shaft-hole fits) should follow the H7/g6 tolerance standard. For example, electronic equipment interfaces only need a tolerance of ±0.02 mm, without pursuing ±0.005 mm. Such adjustments can reduce processing time by 30%.

3.2 Simplify Structures: Reduce “Complex Features”

- Avoid deep cavities (depth > 3 times the diameter): Deep cavity processing requires long tools, which are prone to vibration and precision loss. It is recommended to split deep cavities into 2 shallow cavities; a sensor customer improved processing efficiency by 50% through this optimization;

- Reduce sharp corners: Sharp corners require special tools for processing and can be replaced with rounded corners of R0.5–R1 mm to reduce tool costs and processing time;

- Unify hole diameters: Try to unify the hole diameters of the same milling part (e.g., all φ5 mm) to reduce tool changes and improve efficiency.

3.3 Consider Material Characteristics: Adapt to Processing Processes

- Aluminum Alloy: Suitable for “high-speed milling” and can be designed into thin-walled structures (minimum wall thickness 1 mm). Professional manufacturers can process aluminum alloy thin-walled parts with a minimum wall thickness of 0.8 mm without deformation;

- Stainless Steel: High hardness, so avoid “thin-walled + deep cavity” combinations; the minimum wall thickness is recommended to be ≥2 mm;

- Titanium Alloy: Poor thermal conductivity, prone to heat-induced deformation. Reserve a “processing allowance” of 0.1–0.2 mm during design; combined with “segmented processing + multiple cooling” processes, deformation can be controlled within ±0.002 mm.

4. How to Choose a Reliable CNC Milling Parts Supplier? 5 Key Evaluation Criteria

For procurement personnel, choosing the right supplier is more important than “bargaining.” Based on the common characteristics of top-ranked manufacturers in Google search results, evaluation can be conducted from the following 5 points:

4.1 Qualification Certification: Ensure Compliance and Professionalism

Prioritize manufacturers with “dual certifications”:

- Quality Certifications: ISO 9001 (quality management system), ISO 13485 (medical field), AS9100 (aerospace field). Manufacturers with these three certifications can export products directly to Europe, America, Japan, South Korea, and other markets;

- Production Certifications: UL certification (material safety), CE certification (EU market access), ensuring products meet international market access requirements.

4.2 Production Capacity: Verify “Hard Strength”

- Equipment Configuration: Whether equipped with 5-axis CNC milling machines (e.g., MAZAK 5-axis machines, FANUC 3-axis machines) and high-precision testing equipment (e.g., coordinate measuring machines, roughness meters);

- Production Capacity: Whether the monthly capacity can meet order needs, and whether there is “emergency capacity” (e.g., shortening delivery cycles through two-shift production);

- Process Experience: Whether the manufacturer has served the target industry (e.g., aerospace, medical care, consumer electronics); the number of accumulated cases reflects professionalism.

4.3 Service Efficiency: Reduce Communication and Waiting Costs

- Quotation Speed: Whether supporting “online instant quotation” (generating a detailed quotation within 1 hour after uploading STP/IGS format drawings, including material, processing, and testing costs);

- Prototype Lead Time: Whether small-batch prototypes can be delivered within 3–7 days (3 days for conventional materials, 5 days for special materials);

- After-Sales Support: Whether providing “free rework for quality issues” and “real-time order tracking” (e.g., checking progress through official websites/mini-programs, and responding to quality issues within 48 hours).

4.4 Cost Transparency: Avoid “Hidden Fees”

- Quotation Inclusions: Whether including material, processing, testing, and packaging costs, and whether there are “minimum order quantity (MOQ)” requirements (high-quality suppliers have no mandatory MOQ, starting from 10 pieces, with no hidden fees);

- Bulk Discounts: Whether unit costs decrease in a stepped manner as order quantity increases (e.g., 10% discount for 1,000–5,000 pieces, 20% discount for 5,000+ pieces).

4.5 Customer Reviews: Refer to Real Feedback

Check customer reviews on Google Reviews and industry forums, focusing on “precision stability,” “delivery punctuality,” and “after-sales response speed.” Manufacturers with a customer satisfaction rate of over 90% in the industry are usually more reliable.

5. CNC Milling Parts Frequently Asked Questions (FAQ)

-

Q: What is the processing precision of CNC milling parts?

A: The precision of ordinary milling parts is ±0.01–0.05 mm, while precision milling parts (5-axis processing) can reach ±0.002–0.005 mm. The 5-axis processing workshops of some professional manufacturers can stably achieve a precision of ±0.003 mm, meeting aerospace-grade requirements. -

Q: What materials are needed to customize CNC milling parts?

A: Provide 2D drawings (marked with tolerances and materials), 3D models (e.g., STP/IGS format), and usage scenario descriptions (e.g., temperature, force conditions). Engineers from high-quality suppliers can optimize the design plan for free based on the provided materials to improve processing feasibility. -

Q: Is the cost of small-batch customization (e.g., 50 pieces) high?

A: The cost of small-batch production is 10%–30% higher than that of large-batch production, but manufacturers supporting “rapid prototyping + cost deduction” can reduce costs—for example, the prototype cost of 50 aluminum milling parts is 500 yuan, which can be fully deducted when placing a subsequent order of 1,000 pieces, and the bulk unit price can be as low as 15 yuan/piece. -

Q: How to judge the quality of CNC milling parts?

A: Check from 3 aspects: ① Appearance (no burrs or scratches, surface roughness Ra ≤ 0.8 μm); ② Dimensions (verify tolerances with calipers or coordinate measuring machines, and request inspection reports); ③ Performance (e.g., load-bearing testing, corrosion resistance testing; third-party testing can be requested if needed).

Conclusion

The selection, design, and procurement of CNC Milling Parts is a process of “precisely matching needs”—it is necessary to understand core components and material characteristics, avoid selection misunderstandings, and most importantly, choose a reliable supplier. Whether engineers are designing precision parts or procurement personnel are purchasing in bulk, following the principles of “demand-oriented, data-supported, and authority-verified” ensures that CNC milling parts truly adapt to product needs, reducing costs and improving efficiency.

If you need to customize CNC milling parts, prioritize manufacturers with ISO 9001/AS9100 certification and online instant quotation support, such as XiaMen Goldcattle—equipped with MAZAK 5-axis machines and an intelligent quotation system, it provides 24-hour rapid prototyping and free design optimization and pre-assembly testing services to help you launch projects quickly.