Core Manufacturing Technologies: Engineering for Strength & Lightness

1. Advanced Composite Layup

- Precision fiber placement: Uses 6-axis robotic layup systems to position 3K/6K carbon fiber prepreg (0.125mm thickness) with ±0.5mm accuracy, optimizing fiber orientation (0°/90°/±45°) for load-specific strength. A carbon fiber hood for a sports car with 60% 0° fibers (longitudinal strength) and 40% ±45° fibers (torsional rigidity) achieved 300MPa flexural strength while weighing 5.2kg (65% lighter than steel).

- Variable thickness layup: Engineers adjust ply count (4-24 layers) to create gradient thickness (2-6mm) in high-stress areas—e.g., a carbon fiber front fender with 8 layers at mounting points (4mm) and 4 layers in panel centers (2mm), reducing weight by 15% vs. uniform thickness designs.

- Core integration: Bonds carbon fiber skins to aluminum honeycomb or foam cores (10-20mm thickness) for structural parts like door panels and trunk lids, achieving 200% higher stiffness-to-weight ratio than solid carbon fiber. A luxury EV door panel with Nomex honeycomb core weighed 2.8kg (70% lighter than aluminum) while meeting side impact standards.

2. Autoclave Curing & Dimensional Control

- High-pressure curing: Cures prepreg parts at 120-180℃ and 6-8 bar pressure in autoclaves, eliminating voids (≤1% porosity) and ensuring uniform resin distribution. A carbon fiber roof for a supercar cured at 150℃ achieved 99.5% fiber volume fraction, with tensile strength testing at 1,250MPa (10% higher than industry standards).

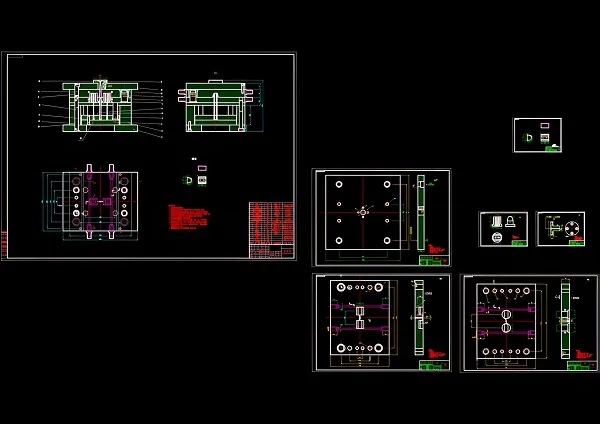

- Tooling precision: Machines aluminum molds (±0.05mm tolerance) with polished surfaces (Ra 0.02μm) to replicate carbon fiber weave patterns and gloss finish, reducing post-curing finishing time by 40%. A 3K twill weave hood achieved mirror-like surface finish (Ra 0.05μm) directly from the mold, requiring no additional polishing.

- Post-cure dimensional stabilization: Subjects parts to 8-hour 120℃ post-cure to reduce residual stress by 80%, ensuring ≤0.1mm/m warpage over -40℃ to 80℃ thermal cycles. A carbon fiber diffuser for racing cars maintained 0.05mm fit tolerance after 500km of track use, critical for aerodynamic performance.

3. Precision Machining & Finishing

- 5-axis CNC trimming: Uses diamond-tipped tools to trim cured carbon fiber parts with ±0.1mm tolerance, cutting complex edges (e.g., headlight openings, mounting flanges) without delamination. A carbon fiber front bumper with 12 mounting holes achieved 0.05mm positional accuracy, ensuring perfect alignment with OEM fenders.

- Clear coating for protection: Applies 2-3 layers of UV-resistant clear coat (80-120μm thickness) with ceramic additives, achieving 95% gloss retention after 3,000 hours UV exposure and resisting rock chips (3H pencil hardness). A 3K carbon fiber interior trim set maintained weave visibility and gloss across 1,000 units, with ΔE <1 color consistency.

- Weave customization: Offers custom weave patterns (twill, plain, forged, herringbone) and resin colors (clear, black, colored), creating unique aesthetics—e.g., a 6K plain weave with red resin for a limited-edition sports car, achieving 98% pattern consistency.

4. Performance Testing & Validation

- Tensile testing: Verifies carbon fiber parts meet 1,000-1,500MPa tensile strength (per ASTM D3039), with 3K twill weave parts averaging 1,200MPa—3x stronger than aluminum (6061-T6).

- Impact resistance: Carbon fiber hoods and fenders undergo 30km/h pendulum impact testing (per FMVSS 208), showing ≤5mm deformation and no sharp edges, meeting pedestrian safety standards.

- Aerodynamic validation: Uses wind tunnel testing to verify performance parts (splitters, diffusers) reduce drag coefficient (Cd) by 5-15%—e.g., a carbon fiber rear wing for a racing car increased downforce by 80kg at 200km/h without excessive drag.

Material Expertise: Matching Carbon Fiber to Car Part Requirements

|

Carbon Fiber Type

|

Resin System

|

Key Properties

|

Application

|

Advantages

|

|

3K Twill Weave Prepreg

|

Epoxy (120℃ cure)

|

1,200MPa tensile strength, 0.05mm weave visibility

|

Body panels, interior trims

|

High-end aesthetics; balanced strength; 50% lighter than steel.

|

|

6K Plain Weave Prepreg

|

Epoxy (180℃ cure)

|

1,500MPa tensile strength, 0.1mm thickness per ply

|

Structural components (door sills, roll cages)

|

Higher strength; cost-effective for high-ply parts.

|

|

Forged Carbon Fiber

|

Polyester resin

|

800MPa tensile strength, random fiber orientation

|

Bumpers, mirror caps

|

Unique marbled finish; 30% faster production than woven.

|

|

Carbon Fiber + Kevlar Hybrid

|

Phenolic resin

|

1,000MPa tensile strength, impact resistance

|

Racing crash structures

|

2x impact absorption vs. pure carbon fiber; FIA compliant.

|

Custom Carbon Fiber Car Parts Manufacturing Process

- Design & FEA Optimization: Engineers collaborate with clients to:

-

- Reduce weight (target: 50-70% vs. steel/aluminum)

-

- Optimize fiber orientation (0° for longitudinal loads, ±45° for torsion)

-

- Ensure OEM fit (mounting holes with ±0.1mm tolerance, edge gaps ≤0.5mm)

- Prototyping:

-

- 3D printed sacrificial molds for small parts (e.g., mirror caps)

-

- Hand-laid carbon fiber prototypes for fit validation (3-5 days)

-

- Functional testing (weight, strength, fit) before tooling

- Tooling production:

-

- CNC machined aluminum molds (±0.05mm tolerance) with heating channels

-

- Release agent application (PTFE-based) for easy part removal

- Composite manufacturing:

-

- Robotic/precision hand layup of carbon fiber prepreg

-

- Autoclave curing (6 bar pressure, 120-180℃) for 2-4 hours

-

- De-molding and flash trimming

- Finishing & quality control:

-

- CNC trimming to final dimensions

-

- Clear coating (2-3 layers) with oven curing

-

- Inspection: CMM for dimensions, ultrasonic testing for voids, gloss meter for finish

Custom Carbon Fiber Car Parts Application Fields

- Luxury & Sports Cars: Carbon fiber hoods, roof panels, and interior trims (e.g., Porsche 911, Ferrari 488 customizations) with 3K twill weave and high-gloss finish.

- Racing & Motorsports: FIA-compliant carbon fiber crash structures, aerodynamic kits (splitters, diffusers), and lightweight seat shells for GT3, Formula, and rally cars.

- Electric Vehicles: Battery covers, door panels, and chassis components (weight reduction improves range by 5-8% for EVs like Tesla Model S custom builds).

- Classic Car Restorations: Carbon fiber body panels (e.g., 1960s Mustang, Jaguar E-Type) that replicate vintage shapes with modern weight savings and durability.

Customization Capabilities: From Concept to Production

- Aesthetic customization:

-

- Weave patterns (3K/6K twill, plain, forged)

-

- Finish options (high gloss, matte, satin, colored resin)

-

- Brand integration (laser-etched logos, contrasting weave accents)

- Performance customization:

-

- Weight targets (e.g., 3kg for a sports car hood)

-

- Strength requirements (FIA, SFI, or OEM standards)

-

- Aerodynamic features (vents, diffuser fins, gurney flaps)

- Fitment options:

-

- OEM vehicle compatibility (BMW M, Mercedes-AMG, Ford Mustang)

-

- Custom build integration (one-off supercars, restomods)

-

- Heritage part replication (vintage shapes with carbon fiber benefits)

- Production scalability: 1-100 units/year (limited editions) to 5,000+ units/year (automotive OEMs), with consistent quality across runs.

Common Customization Questions

- Q: What’s the lead time for a custom carbon fiber hood?

- Q: How durable is carbon fiber in daily driving (rock chips, UV exposure)?

-

- Clear-coated carbon fiber resists rock chips (3H pencil hardness) and maintains gloss (ΔE <2) after 3,000 hours UV exposure.

-

- Minor scratches can be polished; deep damage is repairable with carbon fiber patches and clear coat.

- Q: Can carbon fiber parts be color-matched to car paint?

- Q: What’s the weight savings vs. traditional materials?

-

- vs. steel: 60-70% weight reduction (e.g., 15kg steel hood → 5kg carbon fiber)

-

- vs. aluminum: 30-40% weight reduction (e.g., 8kg aluminum door panel → 5kg carbon fiber)