Introduction

What Are Custom CNC Anodized Motorcycle Parts?

The CNC Machining Advantage

- Exceptional Precision: Tolerances as tight as ±0.01 mm ensure perfect fit and function

- Complex Geometries: Ability to create intricate designs impossible with traditional methods

- Consistency: Each part is identical to the last, ensuring uniformity

- Material Versatility: Works with aluminum, steel, titanium, and other high-performance materials

Anodizing Process Explained

- Corrosion Resistance: Protects against weathering, salt, and chemicals

- Increased Hardness: Surface hardness up to HV400, 3x more wear-resistant

- Color Options: Available in a wide range of colors for customization

- Aesthetic Appeal: Creates a sleek, professional finish that enhances visual impact

Material Selection for Motorcycle Parts

Aluminum Alloys: The Preferred Choice

- Excellent strength-to-weight ratio

- Good corrosion resistance

- Superior machinability

- Ideal for handlebars, levers, brackets, and body components

- Tensile strength: 45 ksi (310 MPa)

- Weight: 2.7 g/cm³

- Higher strength than 6061

- Used in high-stress applications

- Perfect for engine components, suspension parts, and structural elements

- Tensile strength: 83 ksi (572 MPa)

- Weight: 2.81 g/cm³

Other Materials

- Exceptional corrosion resistance

- High strength and durability

- Ideal for exhaust components, fasteners, and brake parts

- Available grades: 304, 316, 416

- Ultra-lightweight and strong

- Excellent corrosion resistance

- Premium material for high-performance applications

- Ideal for exhaust systems, fasteners, and suspension components

- Excellent machinability

- Good corrosion resistance

- Used for decorative parts and fittings

CNC Machining Processes for Motorcycle Parts

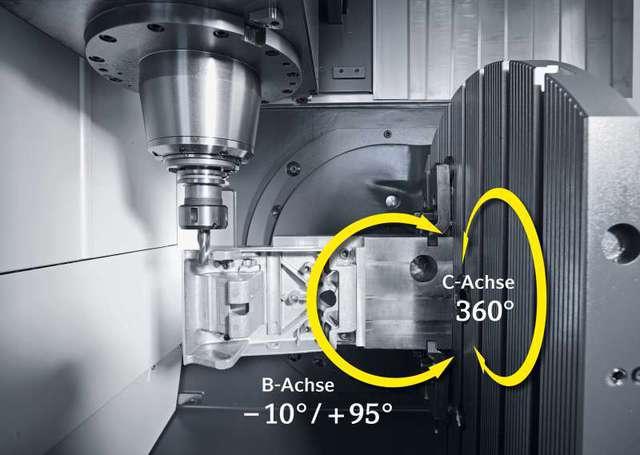

Multi-Axis CNC Milling

- Suitable for simple to moderately complex parts

- X, Y, Z axis movement

- Ideal for flat surfaces, slots, holes, and basic 3D shapes

- Maximum workpiece size: 900 x 600 x 400 mm

- Full 5-axis simultaneous machining

- Capable of complex curved surfaces and undercuts

- Reduces setup time and improves accuracy

- Perfect for engine components, frames, and suspension parts

- Maximum workpiece size: 400 x 400 x 300 mm

CNC Turning

- Handlebars and grips

- Axles and shafts

- Spacers and bushings

- Wheel hubs

- Fuel system components

- Maximum diameter: 250 mm

- Maximum length: 1,000 mm

- Tolerances: ±0.005 mm

- Surface finish: Ra 0.8-1.6 μm

Swiss CNC Machining

- Ideal for small diameter parts (0.5-20 mm)

- Exceptional precision and surface finish

- Used for fasteners, fittings, and small components

Anodizing and Surface Finishing Options

Anodizing Colors and Types

- Clear (natural aluminum appearance)

- Black (matte, semi-gloss, high-gloss)

- Red (various shades)

- Blue (various shades)

- Gold (various shades)

- Silver

- Purple

- Orange

- Green

|

Type

|

Thickness

|

Hardness

|

Applications

|

|

Type I (Chromic Acid)

|

0.0001-0.0007″

|

Soft

|

Decorative, thin coatings

|

|

Type II (Sulfuric Acid)

|

0.0002-0.001″

|

Medium

|

Most common for motorcycle parts

|

|

Type III (Hard Anodizing)

|

0.0005-0.002″

|

Hard (HV400+)

|

High-wear applications

|

Additional Surface Treatments

- Creates a uniform matte finish

- Improves adhesion for anodizing

- Available in various grit sizes (80-320)

- Mirror-like finish

- Enhances aesthetic appeal

- Available in different levels of polish

- Durable, chip-resistant finish

- Wide color selection

- Suitable for high-temperature applications

- Chrome, nickel, gold plating

- Decorative and functional

- Improves corrosion resistance

Applications and Typical Motorcycle Parts

Engine Components

- Engine Covers: Clutch covers, stator covers, timing covers

- Intake Manifolds: Improved airflow for better performance

- Carburetor Parts: Throttle bodies, jets, and fittings

- Engine Mounts: Precision fit for reduced vibration

- Timing Components: Sprockets, chains, and tensioners

Body and Chassis Parts

- Frame Components: Brackets, gussets, and reinforcement plates

- Body Panels: Fairings, fenders, and tank covers

- Handlebars and Controls: Custom handlebars, risers, and clamps

- Foot Pegs and Controls: Brake and shift levers, foot pegs

- Luggage Racks and Accessories: Custom mounting solutions

Suspension and Steering

- Triple Trees: Precision machined for improved handling

- Fork Components: Sliders, caps, and adjusters

- Shock Absorber Parts: Reservoirs, mounts, and adjusters

- Steering Stems and Bearings: Smooth operation and precision

Brake Components

- Brake Discs: Floating and fixed designs

- Calipers: CNC machined for optimal performance

- Brake Levers: Custom designs with adjustable features

- Master Cylinders: Precision machined for smooth operation

Custom Accessories

- Fuel Caps: Custom designs with locking mechanisms

- Oil Filler Caps: Stylish and functional

- Chain Adjusters: Precision alignment tools

- Spools and Stand Adaptors: For maintenance and storage

- Decorative Trim: Custom badges, logos, and accents

Quality Control and Certifications

Quality Assurance System

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- IATF 16949:2016 Automotive Quality Standard

Inspection Equipment

- Coordinate Measuring Machines (CMM): Accuracy ±0.001 mm

- Optical Comparators: For complex shape verification

- Surface Roughness Testers: Measures Ra, Rz parameters

- Hardness Testers: Verifies material and anodize hardness

- Calipers, Micrometers, and Gauges: For dimensional checks

- Vision Inspection Systems: Automated defect detection

Quality Control Process

- Material Inspection: Verify material certification and properties

- In-Process Inspection: Regular checks during machining

- First Article Inspection (FAI): Complete dimensional verification

- Anodize Quality Check: Thickness, color, and adhesion testing

- Final Inspection: Comprehensive testing before shipment

- Documentation: Detailed quality reports and certificates

How to Choose a Custom CNC Motorcycle Parts Supplier

Key Selection Criteria

Technical Capabilities

- Equipment: Ensure they have advanced CNC machines (3, 4, 5-axis)

- Anodizing Facility: In-house anodizing ensures quality control

- Material Expertise: Experience with motorcycle-specific materials

- Design Capabilities: Ability to work from sketches, samples, or CAD files

- Prototyping Services: Rapid prototyping for design verification

Quality Standards

- Certifications: ISO 9001, IATF 16949, etc.

- Quality Control: Comprehensive inspection processes

- Traceability: Material and process traceability

- Warranty: Product warranty and quality guarantee

Experience and Reputation

- Industry Experience: Specialization in motorcycle parts

- Customer Portfolio: References from reputable clients

- Reviews and Testimonials: Positive feedback from customers

- Years in Business: Established track record

Production Capabilities

- Lead Times: Typical delivery times for prototypes and production

- Volume Flexibility: Ability to handle small batches and large production runs

- Customization Options: Range of materials, finishes, and colors

- Engineering Support: Design assistance and DFM (Design for Manufacturability)

Cost Considerations

- Pricing Structure: Competitive pricing for quality work

- Minimum Order Quantities: Flexibility for small orders

- Tooling Costs: Transparent pricing for custom tooling

- Value-Added Services: Additional services that add value

Get Custom CNC Anodized Motorcycle Parts Quote

How to Request a Quote

- Share Your Design: Provide CAD files, sketches, or reference samples

- Specify Requirements: Material, quantity, finish, and delivery timeline

- Get Design Feedback: Our engineers will review your design for manufacturability

- Receive Detailed Quote: Competitive pricing with clear specifications

- Approve and Produce: Once approved, we begin production immediately

Our Customization Process

- Work with our engineering team to refine your design

- Receive recommendations for materials and processes

- Get DFM (Design for Manufacturability) feedback

- Rapid prototype production to verify fit and function

- Test and validate the design before full production

- Make adjustments as needed

- Precision CNC machining to tight tolerances

- High-quality anodizing and surface finishing

- Strict quality control at every stage

- On-time delivery as promised

- Secure packaging to prevent damage

- Worldwide shipping available

Why Choose Us for Your Custom Motorcycle Parts

- 15+ Years Experience: Specialized in motorcycle parts manufacturing

- State-of-the-Art Facility: Advanced CNC machines and anodizing equipment

- Quality Assurance: ISO 9001 certified with strict quality control

- Fast Turnaround: Prototypes in 3-5 days, production in 10-15 days

- Competitive Pricing: Factory direct pricing with no middlemen

- Excellent Customer Service: Responsive communication and support

Frequently Asked Questions (FAQ)

What is the typical lead time for custom parts?

- Prototypes: 3-5 business days

- Small Production Runs (1-50 pieces): 7-10 business days

- Medium Production Runs (50-500 pieces): 10-15 business days

- Large Production Runs (500+ pieces): 15-25 business days

What file formats do you accept for designs?

- STEP (.step, .stp)

- IGES (.iges, .igs)

- STL (.stl)

- DWG (.dwg)

- DXF (.dxf)

- SolidWorks (.sldprt)

- Inventor (.ipt)

What is the minimum order quantity?

- Prototypes: 1 piece minimum

- Production: No minimum order quantity, but pricing improves with volume

- Custom Tooling: May be required for complex parts

What tolerances can you achieve?

- CNC Milling: ±0.01 mm (0.0004″) standard, ±0.005 mm (0.0002″) available

- CNC Turning: ±0.005 mm (0.0002″) standard

- Surface Finish: Ra 0.8-1.6 μm standard, Ra 0.4 μm available

What colors are available for anodizing?

- Clear (natural aluminum)

- Black (matte, semi-gloss, high-gloss)

- Red (various shades)

- Blue (various shades)

- Gold (various shades)

- Silver

- Purple

- Orange

- Green

Can you match existing colors?

What materials do you recommend for different applications?

- Handlebars and Controls: 6061-T6 aluminum

- Engine Components: 7075-T6 aluminum or stainless steel

- Exhaust Parts: Stainless steel or titanium

- Structural Components: 7075-T6 aluminum

- Decorative Parts: 6061-T6 aluminum with anodizing

Do you offer design services?

- CAD modeling from sketches or samples

- Design optimization for CNC machining

- FEA (Finite Element Analysis) for structural parts

- DFM (Design for Manufacturability) analysis

What quality certifications do you have?

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- IATF 16949:2016 Automotive Quality Standard (for automotive parts)

Do you ship internationally?

- Express (DHL, FedEx, UPS)

- Air freight

- Sea freight (for large orders)

- Door-to-door service available

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.

- Phone: +86-18150097490

- Website: https://www.xmgoldcattle.com/

- Address: XiaMen, FuJian, China