Custom CNC Bulldozer Parts is a highly accurate and efficient machining service that combines the advantages of Computer Numerical Control (CNC) technology to provide high quality parts solutions for Bulldozer manufacturers and repairers. The following is a detailed description of Customized CNC Bulldozer Parts:

1.Introduction of customized CNC bulldozer parts service

Customized service scope

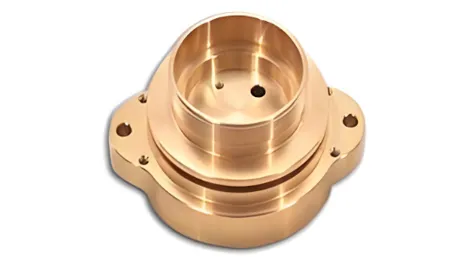

The customized CNC bulldozer parts service provided by Xiamen Goldcattle covers all kinds of key components required for bulldozers, including but not limited to cutter plates, sprockets, chains, bearing housings, cylinders and so on. The company can provide personalized customized solutions according to customers’ specific needs and equipment models to ensure accurate matching and efficient operation of the parts.

Customization process

Demand communication: First of all, the customer needs to contact the company to clarify the specific requirements of the required accessories, including size, material, performance, etc.

Program design: the company’s technical team according to customer requirements, detailed program design, including drawing, process development.

Production and processing: using advanced CNC processing technology, accurate processing of raw materials to ensure the accuracy and quality of the accessories.

Quality Inspection: Strict quality inspection is carried out on the finished fittings to ensure that the products meet customer requirements and industry standards.

Delivery and installation: Deliver the qualified fittings to customers and provide necessary installation guidance and after-sales service.

Technical Advantage

High precision machining: CNC machining technology is adopted to ensure the machining precision and surface quality of the fittings.

Wide choice of materials: different materials can be selected for processing according to customers’ needs to meet the use requirements under different working conditions.

Personalized customization: provide flexible customization service to meet customers’ special needs for accessories.

2.Advantages of customized CNC bulldozer parts service

Customized CNC bulldozer parts service has various advantages, which are mainly reflected in processing accuracy, productivity, flexibility, cost-effectiveness and quality assurance. The following is a detailed description of these advantages:

High precision machining

Computer control: CNC (Computer Numerical Control) machining adopts computer control, through pre-programmed instructions, the machine tool can accurately locate and cut the workpiece, realizing micron-level positioning accuracy and repeatable positioning accuracy. This high-precision machining capability ensures the dimensional and shape accuracy of bulldozer parts, thus improving the performance and reliability of the entire machine.

Reduced errors: The CNC machining process is highly automated, which reduces errors caused by human factors and improves the accuracy and consistency of the machining results.

Improve production efficiency

Automated production: CNC machining equipment with automated functions can continuously and quickly perform a variety of machining tasks, greatly improving production efficiency. Compared with traditional manual operation or ordinary machine tool machining, CNC machining can significantly shorten the production cycle and meet the demand for rapid delivery.

Multi-tasking in parallel: CNC machining equipment can handle multiple workpieces at the same time or perform compound machining, further improving productivity and equipment utilization.

Flexibility and Scalability

Programming Flexibility: CNC machining systems are very flexible and can be programmed and adjusted by the user according to different machining needs. This means that for different models and specifications of bulldozer parts, machining can be realized only by re-programming without replacing a large number of jigs and fixtures, which reduces the production preparation time and cost.

Adaptable: CNC machining can handle parts of all shapes and sizes, including complex geometries and fine details. This makes it able to adapt to the customization needs of different customers and application scenarios, providing diversified solutions for bulldozer parts.

Saving labor costs

Autonomous operation: CNC machining equipment is able to operate autonomously under the supervision of a few operators, reducing the investment in human resources. Compared to traditional machining methods, fewer human resources are required to complete the same quantity and quality of work, thus reducing labor costs.

Reduced labor intensity: Automated machining reduces the labor intensity of workers, improves the working environment, and increases work efficiency and employee job satisfaction.

High quality machined surface

Stable machining: CNC machining process has high precision and stability to produce high quality surfaces. This high quality surface helps to reduce friction and wear during assembly, improving the life and performance of the entire machine.

Reduced post-processing: A high quality machined surface reduces the need for post-grinding and machining, reducing production costs and cycle times.

Traceability and Reliability

Data logging: CNC machining systems can record and save data from the machining process, including tool paths, parameter settings, and more. This data can be used for quality control and traceability needs to ensure product reliability and quality.

Quality control: Through data analysis and monitoring, problems in the machining process can be detected and corrected in time to improve product quality control.

3.Customized CNC bulldozer parts company introduction

Xiamen Goldcattle (Xiamen Xiamen Gold Machinery Co., Ltd.) is an enterprise with deep roots in the field of CNC machinery customization, mainly engaged in mining machinery parts, hardware parts. Rubber plastic parts customization. Since its establishment, the company has always been committed to providing high-quality, high-performance mechanical products and customized services, and has won wide recognition in the market.

Customized CNC Bulldozer Parts FAQ

1. What is Customized CNC Bulldozer Parts service?

Answer: Custom CNC Bulldozer Parts Service refers to the service of using computer numerical control (CNC) technology to machine and manufacture various parts required for bulldozers according to customers’ specific needs. These accessories include, but are not limited to, cutter plates, sprockets, chains, bearing housings, cylinders, etc., and feature high precision, high quality and personalized customization.

2. Why choose Customized CNC Bulldozer Parts?

Answer: There are several reasons for choosing customized CNC dozer parts:

High precision: CNC machining technology can achieve micron-level machining precision, ensuring that the size and shape of the parts meet the strict requirements.

High quality: Automated machining reduces human error and improves the surface quality and overall performance of the parts.

Flexibility: It can be personalized according to customer needs to meet the requirements of different models and working conditions.

Cost-effectiveness: Although the initial investment may be high, in the long run, customized parts can reduce the frequency of repair and replacement and lower the overall cost.

3. What is the process of customized CNC bulldozer parts?

Answer: The process of customized CNC dozer parts generally includes the following steps:

Demand communication: The customer communicates with the service provider to clarify the specific needs of the accessories, including size, material, performance, etc.

Program design: The service provider carries out program design according to the customer’s needs, including drawing, process development and so on.

Material Procurement: Procurement of suitable raw materials according to the design program.

CNC machining: Utilize CNC machining equipment to carry out precision machining to ensure the accuracy and quality of the fittings.

Quality Inspection: Strict quality inspection of the completed fittings to ensure compliance with customer requirements and industry standards.

Delivery and installation: Deliver the qualified parts to customers and provide necessary installation guidance and after-sales service.

4. How long does it take to customize CNC bulldozer parts?

Answer: The time for customized CNC bulldozer parts varies due to many factors, generally 7-15 days can be out of the sample, including the complexity of the parts, machining volume, material availability, production equipment scheduling and so on. Generally speaking, service providers will provide an approximate delivery date after communicating with customers. In order to ensure the delivery date, customers should communicate with the service provider and confirm the specific requirements in advance.

5. How to determine the price of Customized CNC Dozer Parts?

Answer: The price of customized CNC dozer parts is usually determined by a number of factors, including the material, size, quantity, processing difficulty of the parts, and the pricing strategy of the service provider. When communicating with the service provider, customers can ask about the specific quoting methods and price components in order to make a reasonable budget and decision.

Translated with DeepL.com (free version)