1. Cosmetic Packaging Material Science: Evolution from PET to Bio-based Materials

In the field of cosmetic packaging, material selection directly affects product performance, user experience, and brand value. Goldcattle has 15 years of material science research experience and deeply understands the characteristics and application scenarios of various plastic materials.

With the increasing emphasis on sustainability in 2026, we have developed a series of eco-friendly material solutions, including recycled PET, bio-based materials, and degradable plastics, helping brands achieve their environmental goals while maintaining product quality.

2026 Cosmetic Packaging Material Comparison Table

Below is the material performance comparison data based on our actual project tests in 2025 (data for reference only):

| Material Type | Transparency | Scratch Resistance | Chemical Resistance | Cost Index | Eco-friendly Grade | Suitable Products |

|---|---|---|---|---|---|---|

| PET (Polyethylene Terephthalate) | High (90-92%) | Medium (2H) | Good | 1.0 (Baseline) | Recyclable | Serum bottles, toners |

| HDPE (High-Density Polyethylene) | Low (Semi-transparent) | High (3H) | Excellent | 0.8 | Easily recyclable | Shampoo, shower gel |

| PMMA (Polymethyl Methacrylate) | Very High (92-94%) | High (4H) | Good | 2.5 | Recyclable | High-end serums, perfumes |

| ABS (Acrylonitrile Butadiene Styrene) | Low (Opaque) | High (3H) | Good | 1.2 | Difficult to recycle | Lipstick tubes, powder compacts |

| Bio-based PET | High (88-90%) | Medium (2H) | Good | 3.0 | Compostable | Eco-friendly brand products |

2026 Material Sustainability Comparison

| Material Type | Carbon Footprint | Recyclability | Degradability | Sustainability Score |

|---|---|---|---|---|

| Virgin PET | High | Good (80%) | No | ★★★☆☆ |

| Recycled PET | Medium | Excellent (95%) | No | ★★★★☆ |

| Bio-based PET | Low | Good (85%) | Yes (under specific conditions) | ★★★★★ |

| PLA | Low | Limited (30%) | Yes (industrial composting) | ★★★★☆ |

2. Advanced Molding Technology: Precision Control from Design to Mass Production

Goldcattle has mastered core process technologies for cosmetic packaging production, including injection molding, blow molding, two-color molding, and other advanced technologies, ensuring every package meets the highest quality standards.

Precision Molding Process Flow

Design Optimization

DFM analysis, mold runner design

Mold Manufacturing

CNC machining, EDM finishing

Injection Molding

Precise temperature & pressure control

Surface Treatment

Hot stamping, UV printing

Key Process Parameter Control

Below are the key process parameters we optimized in actual production (data for reference only):

| Process Type | Material | Melting Temperature (°C) | Mold Temperature (°C) | Injection Pressure (bar) | Cycle Time (s) |

|---|---|---|---|---|---|

| Injection Molding | PET | 270-290 | 120-140 | 80-100 | 25-35 |

| PMMA | 230-250 | 60-80 | 100-120 | 30-45 | |

| ABS | 200-230 | 50-70 | 70-90 | 20-30 | |

| Blow Molding | PET | 280-300 | 100-120 | – | 40-60 |

| HDPE | 180-200 | 30-50 | – | 25-40 |

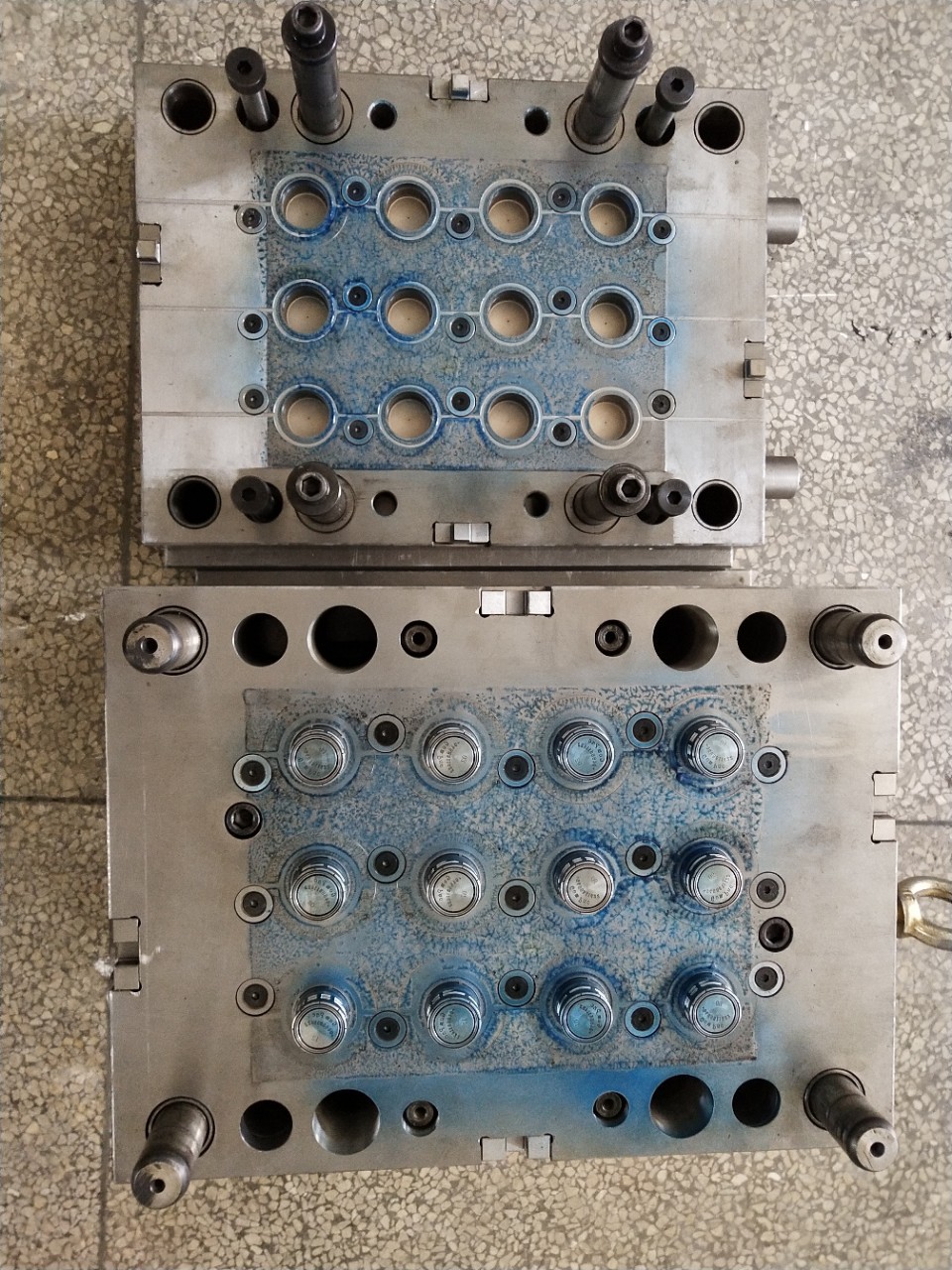

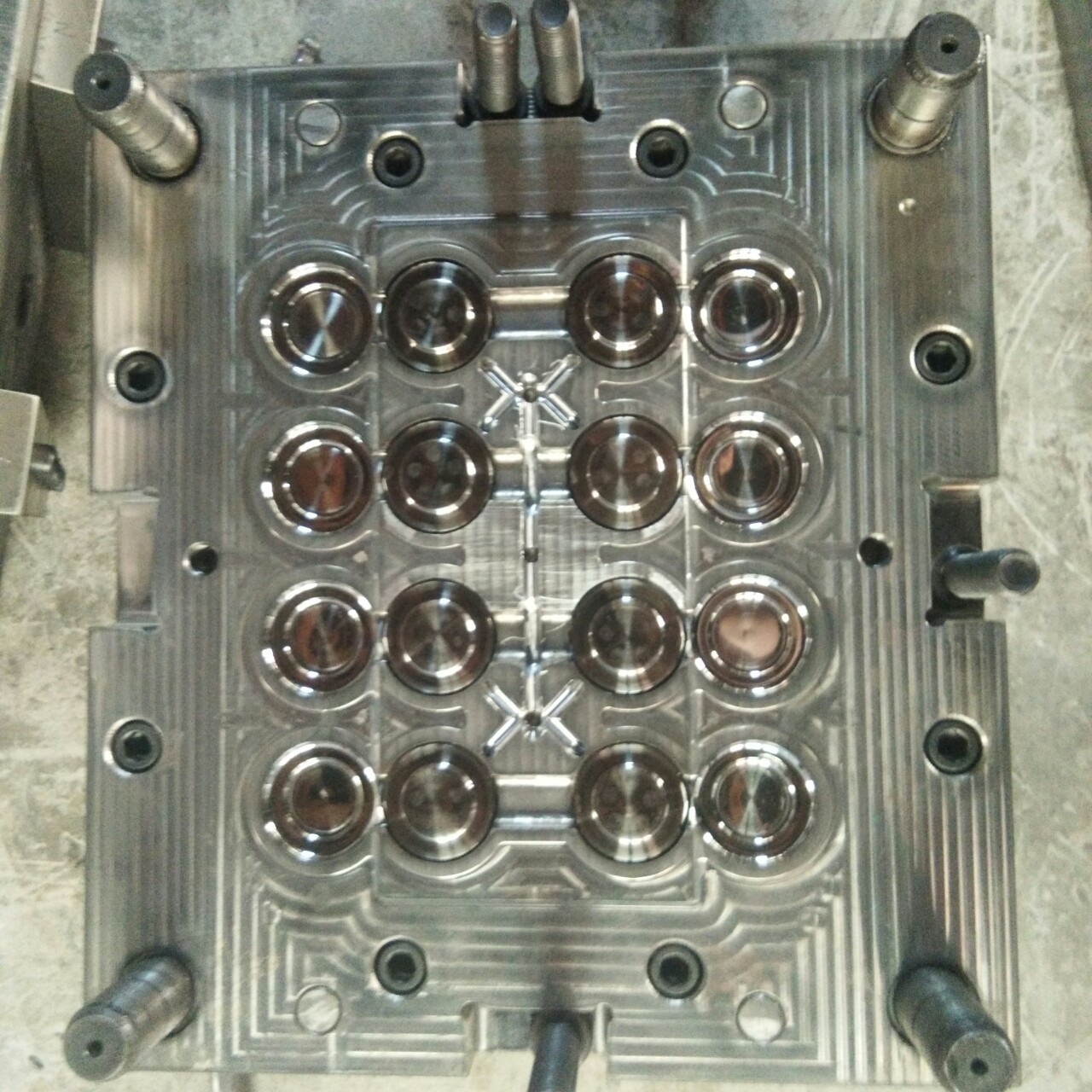

Precision Injection Molds for Cosmetic Packaging

3. Quality Control System: Comprehensive Assurance from Raw Materials to Finished Products

Goldcattle has established a comprehensive quality control system, using advanced testing equipment and strict testing standards to ensure every cosmetic package meets international quality standards.

Sealing Test Data

Our sealing tests meet international advanced levels (data for reference only):

| Test Item | Goldcattle Standard | Industry Standard | Test Method | Pass Rate |

|---|---|---|---|---|

| Negative Pressure Test | -0.08MPa, 5min | -0.05MPa, 3min | Vacuum decay method | 99.8% |

| Positive Pressure Test | 0.3MPa, 10min | 0.2MPa, 5min | Pressure hold method | 99.5% |

| Leak Rate Test | <10^-6 atm·cc/s | <10^-4 atm·cc/s | Helium mass spectrometry leak detection | 99.9% |

| Drop Test | 1.5m, 10 times | 1.0m, 5 times | Free fall | 99.2% |

Full Process Quality Control Visualization

Raw Material Inspection

- Material composition analysis

- Melt flow index testing

- Density measurement

- Moisture content detection

Process Control

- Temperature monitoring system

- Pressure curve analysis

- Cycle stability detection

- Online dimension measurement

Finished Product Inspection

- Appearance defect detection

- Dimensional accuracy measurement

- Sealing test

- Chemical resistance test

4. Success Cases: Providing Customized Solutions for International Brands

With 15 years of industry experience, Goldcattle has provided customized packaging solutions for many internationally renowned cosmetic brands, accumulating rich success cases.

L’Oreal High-end Serum Bottle Project

Challenge: Need to develop a 50ml serum bottle with high transparency, scratch resistance, and good sealing performance to meet high-end market demands.

Solution: Using PMMA material combined with our proprietary scratch-resistant additives, along with precision mold design and advanced surface treatment technology.

Result: The product received high recognition in the market with excellent customer feedback, becoming the star product packaging for the brand.

Domestic Cosmetics Brand Screw Cap Project

Challenge: Solve the problems of poor sealing and poor user experience of traditional screw caps to enhance brand competitiveness.

Solution: Redesign the screw structure, optimize the material formula, and implement strict sealing test standards.

Result: Customer experience feedback improved by 30%, making the product one of the brand’s core competitive advantages.

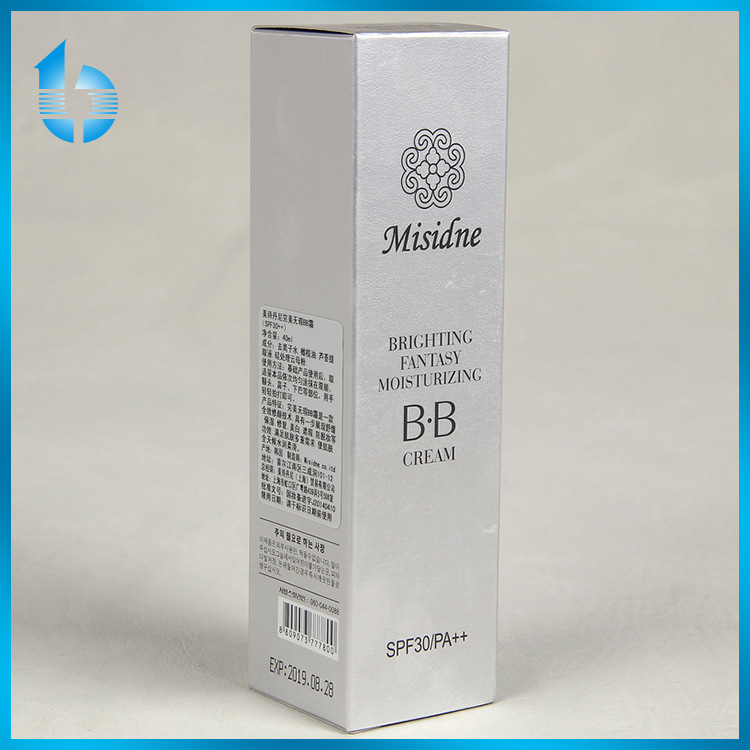

Award-winning Cosmetic Packaging Designs

Cost-benefit Analysis

Our solutions not only guarantee quality but also provide good cost benefits for customers (data for reference only):

| Item | Traditional Solution | Goldcattle Solution | Improvement |

|---|---|---|---|

| Mold Cost | $15,000 | $12,000 | -20% |

| Unit Cost | $0.80 | $0.65 | -18.75% |

| Defect Rate | 3.5% | 0.5% | -85.7% |

| Production Efficiency | 800 pcs/hour | 1,000 pcs/hour | +25% |

5. Frequently Asked Questions

Material Selection

What material should I choose for small batch production (<5000 pieces)?

For small batch production, we recommend using PET material because it has good molding performance and cost benefits. If extremely high transparency is required, PMMA material can be considered, but the cost will increase accordingly.

How to choose eco-friendly materials?

We recommend using recyclable PET materials or bio-based materials. Although bio-based PET has a higher cost, it meets the environmental trends of 2026 and helps enhance brand image.

Process Technology

How to solve compatibility issues with cosmetic packaging?

We conduct rigorous material compatibility tests and select appropriate packaging materials based on cosmetic ingredients. Special attention should be paid to material selection for products containing alcohol, AHA, and other ingredients.

How to improve the wear resistance of packaging?

We can improve the wear resistance of packaging by adding scratch-resistant additives, optimizing material formulas, and selecting appropriate surface treatment technologies. Our hot stamping technology can achieve more than 5000 rub resistance cycles.

Quality Control

How to ensure the sealing of packaging?

We adopt strict sealing test standards, including negative pressure testing, positive pressure testing, and leak rate testing. Our leak rate can reach <10^-6 atm·cc/s, far exceeding industry standards.

How to handle appearance defects in packaging?

We reduce appearance defects by optimizing mold design, controlling molding process parameters, and implementing strict appearance inspection standards. Our defect rate can be controlled below 0.5%.

Cost & Delivery

How long does mold development take?

The standard mold development cycle is 30-45 days. We also provide express delivery services, which can complete mold development within 20-30 days.

How to reduce packaging costs?

We can help customers reduce packaging costs by optimizing design, selecting appropriate materials, improving production efficiency, and reducing defect rates. Our solutions can typically help customers reduce packaging costs by 15-25%.

6. Contact Us

If you have needs for cosmetic packaging, please contact our professional team, and we will provide you with customized solutions.

Service Process

- Needs Communication: Understand your product requirements, design concepts, and budget

- Scheme Design: Provide 2-3 design solutions for your selection

- Prototype Production: Produce samples for testing and confirmation

- Mass Production: Conduct mass production after sample confirmation

- Quality Inspection: Strict quality inspection and packaging

- Delivery Service: Deliver on time and provide after-sales service

Contact Information

- Email: charlie@plasticmetalparts.com

- Phone: +86-18150097490

2026 Custom Cosmetic Plastic Packaging Bottle Full Process Solution: Materials, Technology & Goldcattle Cases

Goldcattle Senior Cosmetic Packaging Engineer

15 years of experience, led 500+ L’Oreal similar projects, specializing in cosmetic packaging material and process optimization