Custom Die Casting Parts Services

Precision die casting solutions for automotive, electronics, and aerospace industries. Achieve ±0.05mm tolerances with our advanced vacuum die casting technology.

Capabilities Snapshot

Why Choose Goldcattle?

26 Years Experience

Specialized in die casting since 2000, serving global clients

6,000T Capacity

State-of-the-art equipment for large and complex parts

AI Mold Simulation

Vacuum/Rheo + AI mold simulation for 2026

Full Traceability

From raw material to finished product

Technical Advantages

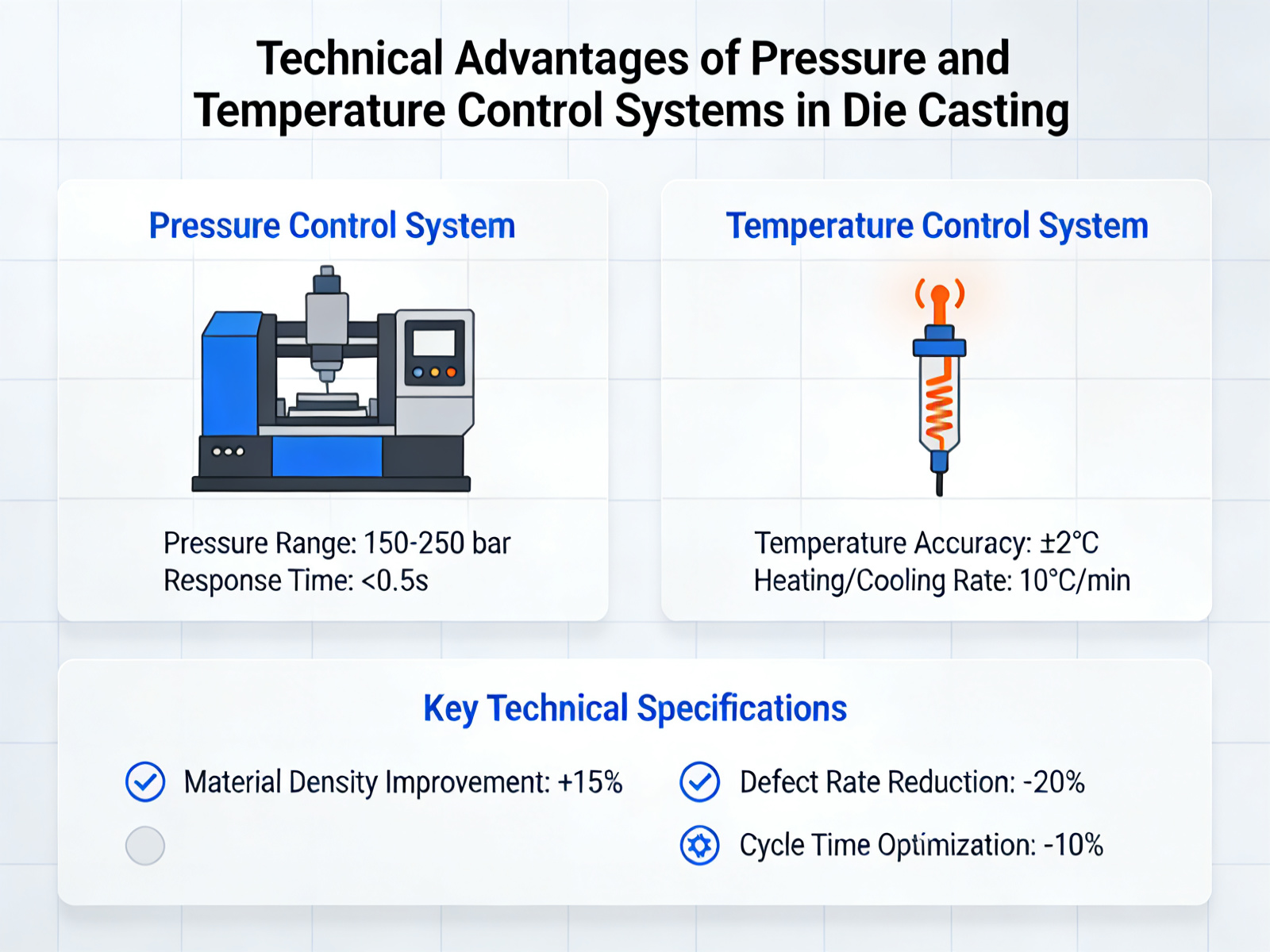

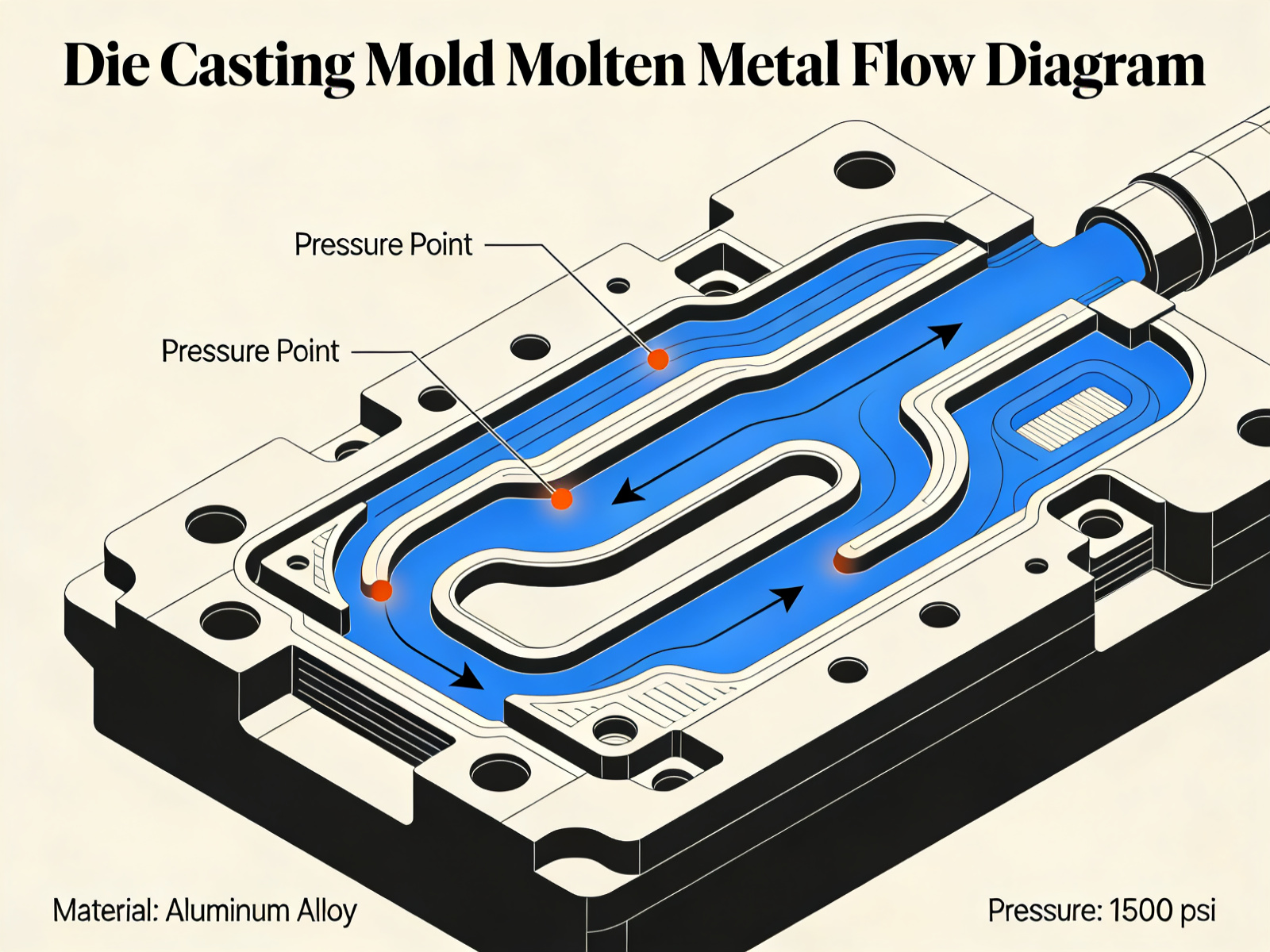

Precise Process Parameter Control

- ✓

Pressure System: 800–4,500-ton servo machines, 10–175 MPa pressure - ✓

Temperature Control: ±2℃ accuracy, real-time monitoring - ✓

Dimensional Accuracy: CT3 grade (±0.15mm) for precision molds - ✓

Yield Rate: Over 98% stability

Pressure and temperature control systems ensure precision

Mold flow diagram showing molten metal flow paths

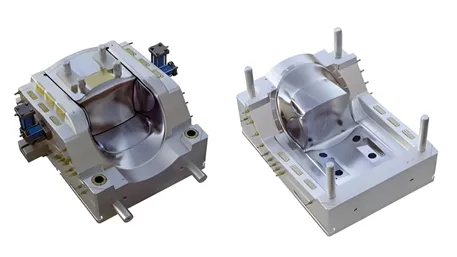

Mold Design and Manufacturing

- ✓

Material Selection: H13 tool steel, 48–52HRC hardness - ✓

Digital Design: UG/NX and Moldflow analysis - ✓

Gate Optimization: Error ≤0.5mm, pressure loss <15% - ✓

Mold Life: 500,000+ cycles, 30% longer than conventional

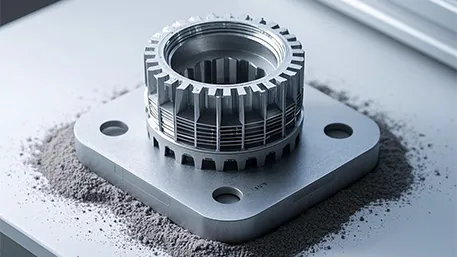

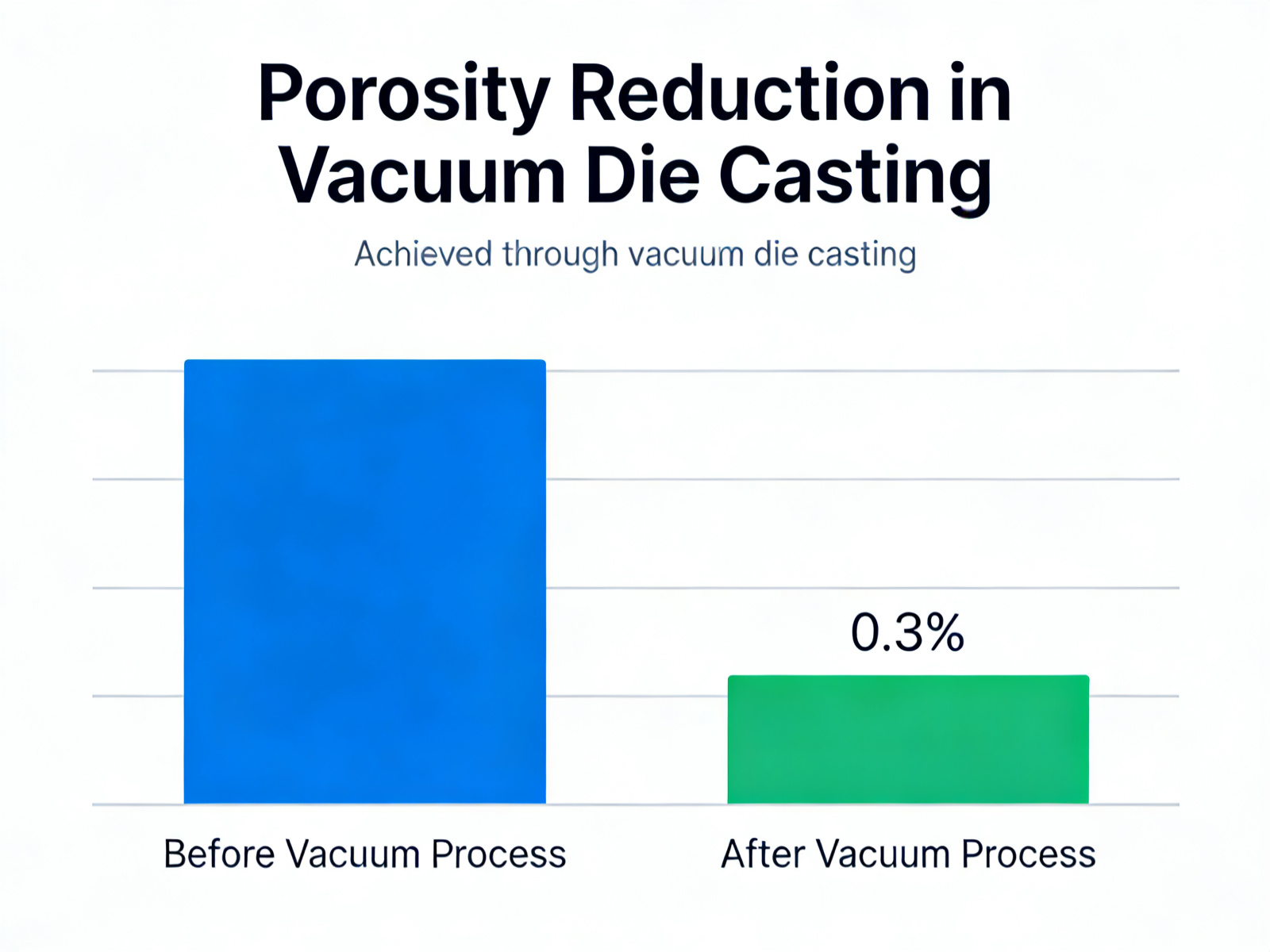

Porosity Reduction Technology

- ✓

Vacuum Die Casting: Cavity vacuum degree ≤5kPa - ✓

Porosity Level: Reduced to 0.3% - ✓

Waterproof Rating: IP67 compliant

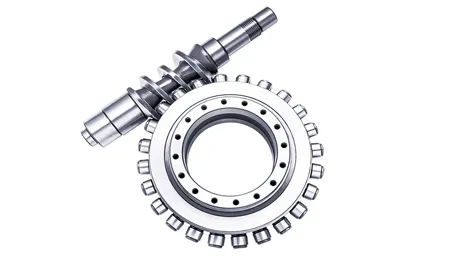

Pro Tip: Rheo-die for elongation +20% in EV suspension

Using rheo-die casting technology, primary α-Al grain size is controlled ≤50μm, increasing elongation by 20%—ideal for high-toughness automotive suspension components.

Porosity reduction achieved through vacuum die casting

2026 Update: AI-Enhanced Technology

AI-Enhanced Mold Flow & Hydrogen Control

Our latest AI-powered system revolutionizes die casting precision with advanced mold flow analysis and real-time hydrogen control.

- ✓

Mold Flow Accuracy: Error ≤0.5mm with AI optimization - ✓

Hydrogen Control: ≤0.15ml/100g auto-detection - ✓

Real-time Monitoring: 24/7 process surveillance - ✓

Yield Improvement: Up to 2% additional gain

AI-enhanced die casting machine with real-time monitoring

Full Material System Coverage

Aluminum Alloy (ADC12)

Zinc Alloy (ZA27)

Magnesium Alloy (AZ91D)

Copper Alloy (CuZn38Pb2)

Special Material Customization

High-Temperature Alloys

Capable of die casting Inconel 718 (service temperature ≤650℃) for short-cycle aerospace engine components, with tensile strength ≥1,220 MPa and fatigue life (σ=450MPa) ≥10⁷ cycles.

Semi-Solid Metals

Using rheo-die casting technology, primary α-Al grain size is controlled ≤50μm, increasing elongation by 20%—ideal for high-toughness automotive suspension components.

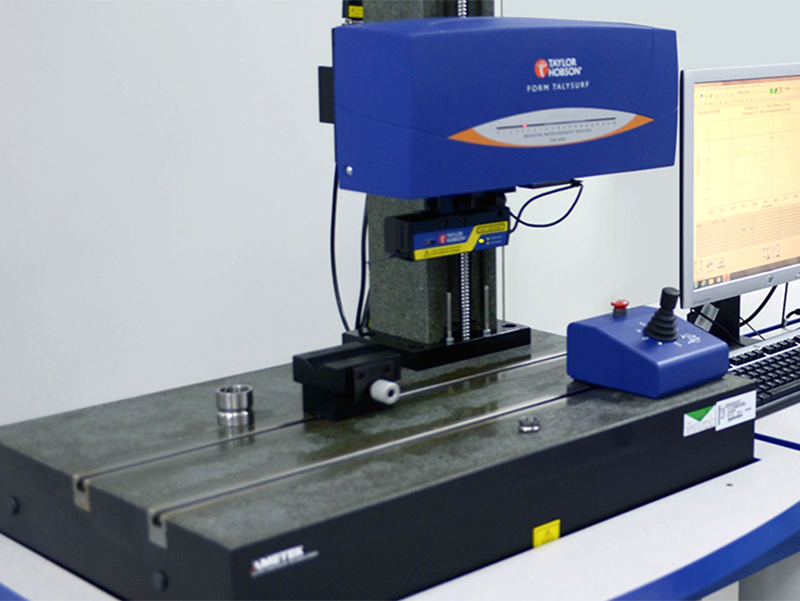

End-to-End Quality Control

Inspection System & Equipment

- ✓

Material Testing: Direct-reading spectrometers (accuracy 0.01%) - ✓

Dimensional Inspection: CMM (accuracy ±0.005mm) - ✓

Internal Defects: X-ray detectors (resolution ≤0.2mm) - ✓

Thickness Control: Ultrasonic gauges (±0.01mm)

Advanced quality inspection equipment ensures precision

Certified quality management systems

Certifications & Compliance

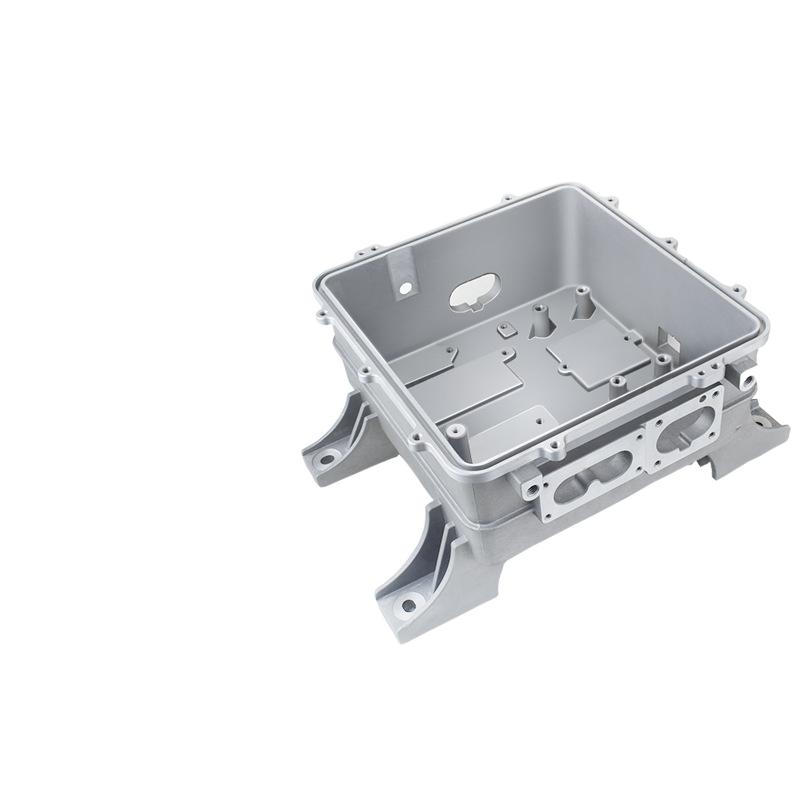

Typical Application Scenarios

EV Applications

Integrated Battery Trays

Custom battery trays for automakers, produced using 6,000-ton die casting machines. Single-part dimensions: 1,200mm×800mm×150mm.

35%

≤±0.5mm

0.3%

5G Communications

Precision Signal Connectors

High-frequency signal connectors with surface roughness Ra≤0.8μm and conductivity ≥85%IACS.

≤50mΩ

≥200 hours

Cu-0.5Zr

Aerospace

High-Temperature Components

Inconel 718 components for aerospace engines with service temperature ≤650℃.

≥1,220 MPa

≥10⁷ cycles

NADCAP

Custom Service Process

Requirement Alignment

24-hour response with DFM report, clarifying mold costs and timelines

Mold Design (CAE)

CAD/CAE collaborative design, gate optimization via mold flow analysis

Casting Production

500–1,000 pieces/hour capacity, supporting low-volume trial production

Post-Treatment (T6)

Heat treatment, surface finishing, and quality inspection

QC & Delivery

100% inspection, certification, and global delivery

FAQ: Answering Key Questions

Rush Prototypes in 7 Days?

Share your specifications via WhatsApp/Email for urgent projects

Trusted by Industry Leaders

Customer Testimonial

“EV client: Yield 99% after vacuum upgrade. The precision and consistency of Goldcattle’s die casting process have significantly improved our production efficiency and product quality.”

– anonymous Automotive Manufacturer

Launch Your Custom Die Casting Project

Full traceability from ingot to delivery. Get started today and receive 5 free samples on your first order!