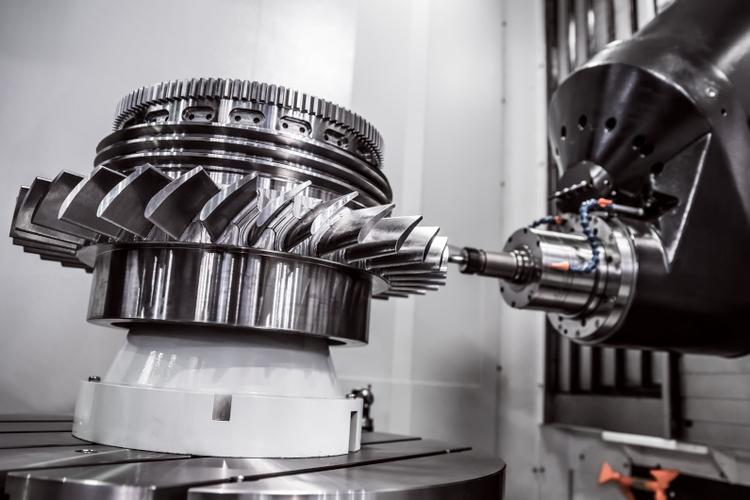

From the rugged enclosures protecting factory machinery to the precision brackets holding automotive systems together, industrial equipment relies on components that balance strength, durability, and exact fit. These workhorse components are often custom industrial sheet metal stamping parts—metal pieces shaped by controlled force and precision tooling to meet unique design requirements. At Goldcattle, with decades of expertise in metal fabrication, we transform raw metal sheets into tailored solutions that power industries worldwide. Let’s explore how custom industrial sheet metal stamping delivers unmatched value, the technology behind it, and why Goldcattle is your trusted partner for precision metal parts.

What Are Custom Industrial Sheet Metal Stamping Parts?

Custom industrial sheet metal stamping is a manufacturing process where flat metal sheets (typically 0.1–6mm thick) are shaped into 3D components using specialized dies and presses. Unlike off-the-shelf metal parts, custom stamping allows for precise control over dimensions, shapes, and features—from simple brackets with holes to complex enclosures with bends and embossments.

The magic lies in its efficiency: stamping applies force (up to 2,000 tons in industrial presses) to deform metal into the exact shape of a die, creating consistent parts at high volumes. For industrial applications, this means components that fit perfectly, withstand heavy use, and meet strict performance standards—all while keeping production costs manageable .

Key Technologies in Custom Industrial Sheet Metal Stamping

1. Stamping Processes: From Flat Sheet to Finished Part

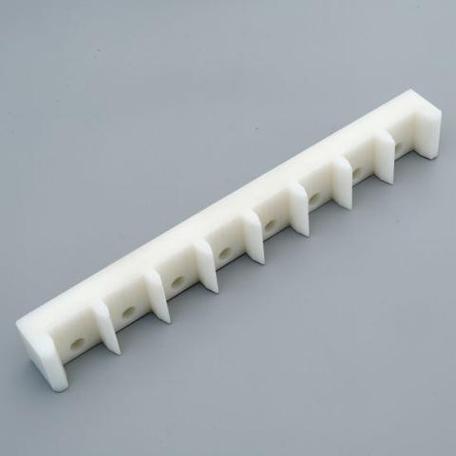

Custom industrial sheet metal stamping relies on a suite of processes tailored to part design:

- Blanking & Piercing: Cutting flat shapes (blanking) or holes (piercing) from metal sheets with precision dies, achieving tolerances as tight as ±0.1mm for critical mounting holes .

- Bending: Using press brakes to fold metal into angles (90°, 135°, etc.) with consistent bend radii—essential for structural brackets and enclosures. Goldcattle’s CNC press brakes achieve bend accuracy of ±0.5° even for thick (4mm) steel sheets.

- Drawing & Forming: Transforming flat sheets into hollow or curved parts (like tanks or curved panels) by stretching metal over dies. This process creates seamless components with high strength-to-weight ratios.

- Embossing & Coining: Adding raised or recessed features (logos, reinforcement ribs) to enhance functionality or branding without compromising structural integrity.

Our 1,000-ton hydraulic press, for example, recently produced 10,000 industrial motor brackets with 3 precise bends and 4 mounting holes, maintaining 0.05mm dimensional consistency across all units.

2. Materials: Choosing the Right Metal for the Job

Custom industrial sheet metal stamping thrives on material versatility, with options selected based on strength, corrosion resistance, and cost:

- Cold-Rolled Steel (CRS): Smooth surface finish and high strength (tensile strength 370–500 MPa), ideal for structural brackets and machine frames .

- Stainless Steel (304/316): Corrosion-resistant and durable, used in food processing equipment, chemical tanks, and outdoor enclosures. 316 stainless adds superior resistance to saltwater and chemicals .

- Aluminum (5052/6061): Lightweight (2.7 g/cm³) with good formability, perfect for automotive parts, HVAC components, and portable industrial equipment.

- Galvanized Steel: Zinc-coated for rust resistance, used in outdoor structures, electrical enclosures, and agricultural machinery.

Goldcattle’s material experts recently helped a client switch from mild steel to 5052 aluminum for their conveyor system brackets, reducing weight by 40% while maintaining required load capacity (150kg per bracket).

3. Tooling: The Foundation of Precision Stamping

High-quality custom industrial sheet metal stamping starts with precision tooling (dies). Goldcattle’s in-house tooling shop crafts dies from hardened steel (H13 or D2) to ensure durability:

- Progressive Dies: Process metal in multiple stages (blanking, bending, piercing) in one pass, ideal for high-volume parts (100,000+ units) and reducing production time by 30% .

- Compound Dies: Perform multiple operations (e.g., blanking + piercing) in a single press stroke, ensuring tight tolerances for parts with closely spaced features.

- Custom Dies: Tailored to unique part geometries, from simple brackets to complex enclosures with multiple bends. Our dies maintain accuracy for 500,000+ cycles before requiring maintenance.

For a client’s custom control panel enclosure, our progressive die integrated 7 operations (blanking, 3 bends, 2 piercings, 1 embossment) into one process, cutting lead time from 6 weeks to 3 weeks.

Goldcattle’s Custom Industrial Sheet Metal Stamping Process

Our end-to-end workflow ensures every part meets your specifications:

- Design & DFM Analysis: Our engineers review your CAD files to optimize for stamping—checking bend radii (minimum 1x material thickness to prevent cracking), hole placement (minimum distance from edges: 2x material thickness), and material selection.

- Tooling Design & Fabrication: We design and machine dies using CNC milling and EDM, with critical surfaces finished to Ra 1.6μm for smooth part release.

- Stamping Production: Parts are formed on our CNC presses (30–2,000 tons) with real-time monitoring to ensure consistent force and precision.

- Quality Inspection: Every batch undergoes CMM (Coordinate Measuring Machine) checks for dimensional accuracy, with key features verified to ±0.05mm tolerance.

- Post-Processing: Services like powder coating (for corrosion resistance),electroplating for conductivity, or deburring (for safety) add final functionality.

Applications: Industries Powered by Custom Sheet Metal Stamping

Industrial Machinery

From factory robots to packaging equipment, custom stamping creates frames, guards, and brackets that withstand vibration and heavy loads. Goldcattle’s stamped steel guards for a client’s assembly line robots reduced downtime by 25% by preventing debris damage to moving parts.

Automotive & Transportation

Truck chassis brackets, engine mounts, and trailer components rely on stamping for strength and consistency. Our stainless steel exhaust system brackets for a commercial vehicle manufacturer met strict heat resistance requirements (up to 300°C) and lasted 100,000+ miles.

Renewable Energy

Solar panel frames, wind turbine housings, and battery enclosures use custom stamping for lightweight durability. We produced aluminum solar panel mounting brackets with 0.1mm bend accuracy, ensuring perfect alignment during installation.

HVAC & Construction

Ductwork, ventilation grilles, and structural supports benefit from stamping’s efficiency. A construction client used our galvanized steel duct connectors to reduce on-site assembly time by 40% compared to welded alternatives.

FAQs About Custom Industrial Sheet Metal Stamping Parts

Q: What’s the size range for custom stamped parts?

A: We handle parts from 50x50mm (small brackets) up to 3000x1500mm (large enclosures), with material thickness from 0.1mm to 6mm.

Q: What tolerances can you achieve in stamping?

A: For general parts: ±0.1mm. For critical features (e.g., mounting holes): ±0.05mm using precision dies and CNC presses .

Q: How long does tooling take for a custom part?

A: Simple dies (blanking/piercing) take 2–3 weeks. Complex progressive dies take 4–6 weeks, but we offer expedited options for urgent projects.

Q: What’s the minimum order quantity (MOQ) for custom stamping?

A: We accommodate small batches (100–500 units) with economical tooling, and scale to high-volume production (100,000+ units) with progressive dies.

Q: Can you stamp parts with complex geometries?

A: Yes! Our 5-axis press brakes and custom dies handle parts with multiple bends (up to 12 bends), embossments, and tight radii—recently producing a medical equipment enclosure with 8 bends and 0.08mm tolerance.

Ready to Transform Your Metal Part Design?

Custom industrial sheet metal stamping parts are the backbone of reliable, efficient industrial equipment—and Goldcattle has the expertise to turn your design into a high-performance reality. Whether you need a single prototype or mass-produced components, we deliver strength, precision, and value in every part.

Visit https://www.xmgoldcattle.com/ to upload your design or request a quote. Let’s engineer a custom stamping solution that meets your industry’s toughest demands.

Got a challenging part design? Share your requirements below—our stamping experts are ready to help optimize your project!