Custom machined aluminum parts serve as critical components in modern manufacturing, bridging precision engineering and functional performance across industries. From aerospace to electronics, their ability to balance strength, weight, and adaptability makes them indispensable in high-performance systems. This article breaks down the technical fundamentals of these components, covering material science, manufacturing processes, and real-world implementation.

1. Material Properties and Alloy Selection

Aluminum’s intrinsic characteristics make it a staple in precision machining. With a density of 2.7 g/cm³, it offers a 66% weight advantage over steel while maintaining sufficient structural rigidity for most industrial applications. The material’s thermal conductivity (205 W/m·K for pure aluminum) enables efficient heat dissipation, critical for electronic and automotive components.

Key alloys for machining include:

- 6061-T6: Tensile strength of 310 MPa with 12% elongation, balancing machinability and corrosion resistance. Used in 70% of general-purpose machined parts.

- 7075-T6: Delivers 503 MPa tensile strength, ideal for high-load applications like aerospace brackets. Contains 5.6-6.1% zinc for enhanced hardness.

- 5052-H32: Offers 230 MPa tensile strength and 15% elongation, with superior saltwater resistance—used in 85% of marine-grade machined components.

- 2024-T3: Features 470 MPa tensile strength but lower corrosion resistance, primarily used in aircraft structural parts where strength outweighs environmental exposure concerns.

Alloy selection directly impacts machining parameters: 6061 requires 20-30% lower cutting force than 7075, reducing tool wear by 40% in mass production.

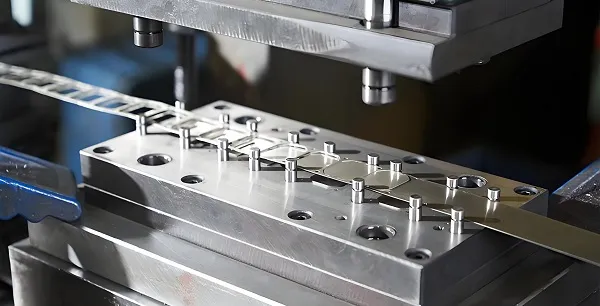

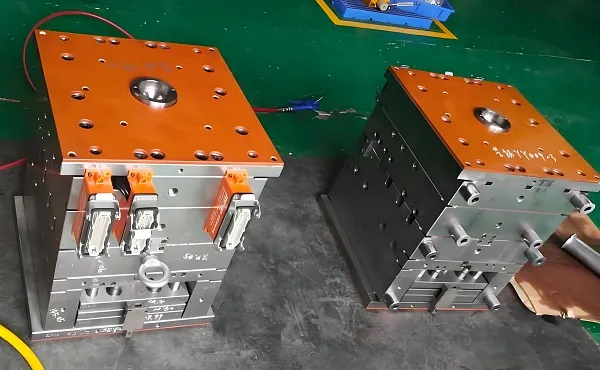

2. Precision Machining Technologies

Modern machining processes for aluminum parts achieve exceptional accuracy through advanced techniques:

CNC milling systems with 5-axis capabilities maintain positional accuracy of ±0.002 mm, enabling complex geometries like contoured aerospace fittings. Spindle speeds up to 20,000 RPM allow for high-speed machining, reducing cycle times by 35% compared to conventional methods.

Turning operations on CNC lathes produce cylindrical parts with surface finishes as fine as Ra 0.8 μm. Live tooling attachments eliminate secondary operations for features like keyways, reducing production time by 25% for shaft components.

Electrical Discharge Machining (EDM) achieves tolerance levels of ±0.001 mm for intricate features such as micro-holes (0.1-0.5 mm diameter) in mold inserts. Wire EDM can cut 0.02 mm kerf widths, essential for precision gears and medical instrument components.

3. Surface Treatment Processes

Surface modifications enhance performance characteristics of machined aluminum parts:

Anodizing creates an oxide layer (5-250 μm thick) with hardness up to 300 HV, increasing wear resistance by 300% compared to untreated surfaces. Type II anodizing (20-30 μm) is standard for decorative applications, while Type III (hard anodizing) reaches 50-100 μm for industrial components.

Electroless nickel plating deposits a 5-50 μm layer with 500-600 HV hardness, providing corrosion resistance exceeding 1,000 hours in salt spray testing (ASTM B117). This treatment is specified for 65% of aluminum hydraulic components.

Powder coating applies a 40-120 μm polymer layer with impact resistance exceeding 16 ft-lbs (ASTM D2794). The process achieves 95% material utilization, superior to liquid painting’s 60-70% efficiency.

4. Design Optimization for Machining

CAD/CAM integration enables design for manufacturability (DFM) principles that reduce production costs by 20-40%:

Fillets and radii larger than 0.5 mm minimize tool breakage in CNC milling. Internal corners with radii matching standard end mill sizes (3-6 mm) reduce cycle times by 15% compared to sharp corners requiring special tools.

Wall thickness should maintain a 1:4 ratio (thickness to height) for aluminum to prevent warping during machining. Parts with 2 mm walls can reliably reach 8 mm heights without distortion, while 1 mm walls require height limitations of 4 mm.

Undercuts deeper than 3× the tool diameter increase setup time by 50%. Incorporating 3° draft angles on vertical surfaces eliminates the need for secondary operations in 75% of cases.

5. Quality Control and Compliance

Rigorous inspection protocols ensure part conformity:

Coordinate Measuring Machines (CMMs) with 0.5 μm accuracy verify dimensional compliance. Critical features require CMM sampling at 100% for aerospace components, while automotive parts typically use 10% AQL (Acceptable Quality Level) standards.

Material verification via spectrometric analysis confirms alloy composition within ±0.1% for critical elements. 7075 aluminum must maintain zinc content between 5.6-6.1% to achieve specified mechanical properties.

Ultrasonic testing at 2-10 MHz detects subsurface defects larger than 0.1 mm in diameter. This method is mandatory for 100% of aluminum parts used in aircraft structural applications (per AMS 2631).

6. Cost Analysis and Production Efficiency

Material utilization rates average 70-85% for CNC machining of aluminum parts, significantly higher than casting’s 50-60% yield. Scrap aluminum from machining operations retains 95% of its original value due to high recyclability.

Production volume directly impacts unit costs:

- 100-piece runs: $50-150 per part (setup costs dominate)

- 1,000-piece runs: $15-40 per part (optimized tool paths reduce per-unit time)

- 10,000-piece runs: $5-15 per part (volume discounts on raw materials apply)

Tooling costs for aluminum machining are 30-50% lower than for steel due to reduced wear. Carbide end mills last 800-1,200 parts when machining 6061 aluminum, compared to 300-500 parts for 4140 steel.

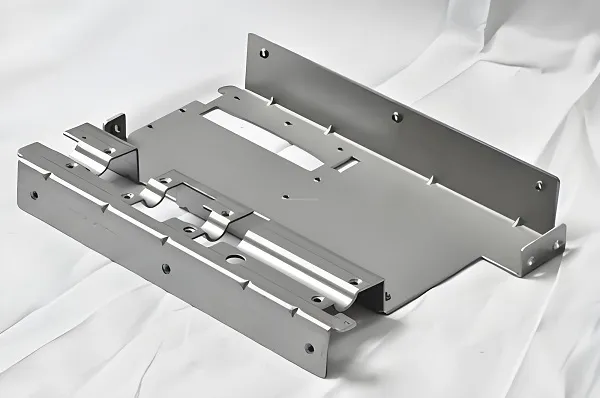

7. Industry-Specific Applications

Aerospace applications utilize 7075-T6 machined parts for wing spars and landing gear components, where each kg of weight reduction saves approximately $1,000 in lifetime fuel costs for commercial aircraft. The Boeing 787 uses over 11,000 custom machined aluminum parts, reducing overall airframe weight by 15% compared to previous models.

Automotive manufacturers specify 6061-T6 for suspension components, achieving 40% weight reduction over steel equivalents while maintaining 300 MPa tensile strength. A typical electric vehicle contains 45-60 kg of machined aluminum parts, contributing to 8-10% increased range through reduced vehicle mass.

Medical devices employ 5052 aluminum machined parts for surgical instrument trays, where the alloy’s corrosion resistance meets ISO 10993 biocompatibility standards. These components undergo 0.8 μm surface finishing to prevent bacterial adhesion.

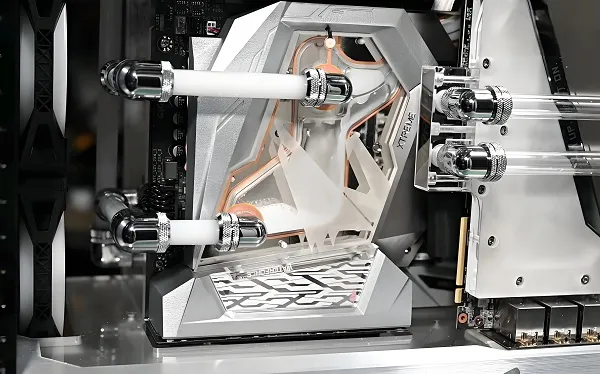

Electronics enclosures utilize anodized 6061 aluminum with 50-75 μm oxide layers, providing EMI shielding effectiveness of 60-80 dB at frequencies up to 1 GHz. Heat sinks machined from 6063 aluminum achieve thermal resistance as low as 0.15°C/W, critical for high-performance processors.

Frequently Asked Questions

Q: How do I choose between 6061 and 7075 aluminum for my project?

A: Select 6061 for general applications requiring a balance of machinability and corrosion resistance. Choose 7075 when high strength (over 500 MPa) is critical, such as aerospace load-bearing components, and corrosion resistance can be managed through surface treatments.

Q: What’s the maximum precision achievable in aluminum machining?

A: Advanced CNC systems and EDM can achieve tolerances as tight as ±0.001 mm, with surface finishes down to Ra 0.8 μm. Precision is influenced by alloy type, with softer alloys like 6061 allowing finer finishes than high-strength 7075.

Q: How does surface treatment affect part dimensions?

A: Anodizing adds 50-100% of the coating thickness to part dimensions (e.g., a 20 μm anodized layer increases diameter by ~20 μm). Electroless nickel plating typically adds 5-50 μm, requiring pre-machining allowances for critical tolerances.

We hope this technical overview helps clarify key aspects of custom machined aluminum parts. If you have specific questions about alloy selection, machining processes, or application-specific challenges, feel free to share your thoughts in the comments below—our team of engineers will be happy to provide detailed insights.