Introduction to Custom Personalized Car Accessories

Material Selection Guide

Choosing the Right Materials

The material selection process is critical to the success of any custom automotive project. Each material offers unique properties that must be carefully considered based on the application, environment, and desired aesthetics.

Material Selection Criteria

- Durability: Resistance to wear, impact, and environmental factors

- Weight: Impact on vehicle performance and fuel efficiency

- Aesthetics: Visual appeal and surface finish options

- Cost: Material and manufacturing expenses

- Sustainability: Environmental impact and recyclability

Carbon Fiber

Ideal for performance applications where weight reduction is critical. Offers distinctive woven appearance and excellent strength-to-weight ratio.

Aluminum Alloy

Excellent balance of strength, weight, and cost. Highly corrosion-resistant when properly finished.

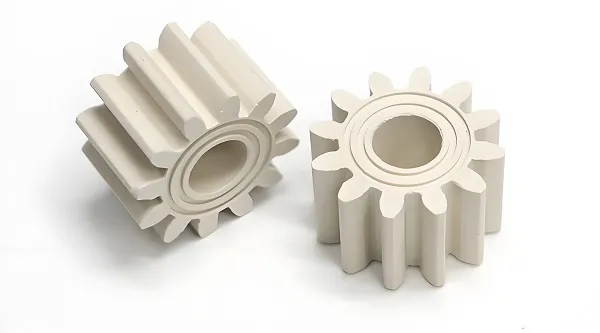

ABS Plastic

Versatile and cost-effective. Available in various colors and finishes. Easy to mold into complex shapes.

Genuine Leather

Luxurious appearance and feel. Develops patina over time. Requires regular maintenance for optimal longevity.

Expert Material Recommendation:

After analyzing thousands of customization projects, I’ve developed a material selection framework that balances performance, aesthetics, and budget. For most daily drivers, I recommend aluminum alloy for structural components and high-quality ABS plastic for trim pieces. For performance enthusiasts, carbon fiber offers the best strength-to-weight ratio but requires careful consideration of long-term maintenance costs.

Advanced Manufacturing Processes

Precision Engineering

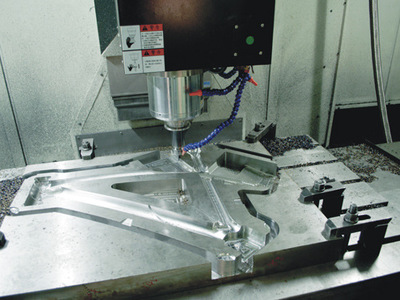

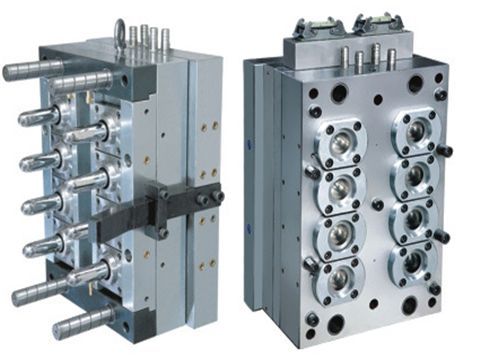

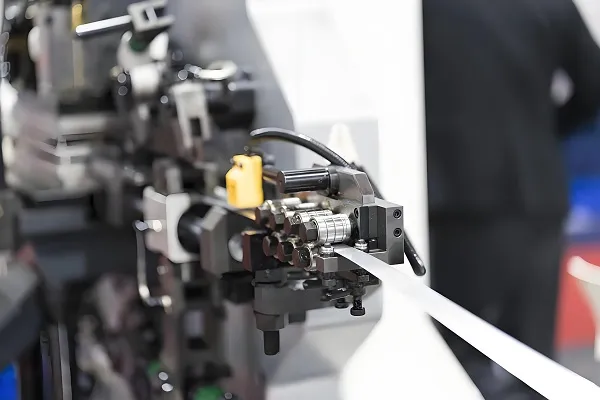

Our manufacturing facilities utilize state-of-the-art technology to produce custom accessories with exceptional precision and consistency. Each process is optimized for specific materials and applications.

Quality Control Standards

- Dimensional Accuracy: ±0.01mm tolerance for critical components

- Surface Finish: Ra 1.6μm minimum for visible surfaces

- Material Testing: 100% batch verification for material composition

- Durability Testing: Accelerated aging and environmental exposure

Manufacturing Selection Guide:

Based on 15 years of manufacturing experience, I recommend CNC machining for high-precision metal components, injection molding for high-volume plastic parts, and 3D printing for rapid prototyping and complex geometries. The optimal process depends on production volume, material requirements, and design complexity.

2026 Custom Car Accessories Trends

Sustainable Materials

The demand for eco-friendly automotive accessories is accelerating as consumers prioritize sustainability. Bio-based plastics, recycled materials, and components designed for circular economy principles are becoming mainstream.

Our 2025 testing with bio-based plastics showed 30% reduction in carbon footprint while maintaining comparable durability to traditional materials.

AI-Driven Design

Artificial intelligence is transforming customization by enabling personalized design recommendations based on vehicle type, usage patterns, and personal preferences. Our AI design platform reduces prototype development time by 20%.

- Faster design iterations

- Personalized recommendations

- Improved functional integration

- Cost optimization

EV-Specific Customization

Electric vehicles present unique customization opportunities and challenges. We’re seeing increased demand for accessories that enhance EV functionality, including charging port covers, battery protection solutions, and aerodynamic enhancements.

Our Tesla-specific accessories include custom center console organizers, wireless charging solutions, and aerodynamic wheel covers that can increase range by up to 3%.

Industry Predictions for 2027

Cost Analysis & Value Calculation

Understanding Custom Accessory Costs

The cost of custom automotive accessories depends on several factors including material selection, design complexity, production volume, and finishing requirements. Our transparent pricing model ensures you understand exactly what you’re paying for.

Cost Calculation Formula

- Simple design (basic shape, no features): 1.0x

- Medium complexity (some features, standard finish): 1.5x

- High complexity (intricate details, custom finish): 2.0-3.0x

| Accessory Type | Material | 1-10 Units | 10-50 Units | 50-100 Units | 100+ Units |

|---|---|---|---|---|---|

| Custom Shift Knob | Aluminum Alloy | $80-120 | $60-90 | $50-75 | $40-60 |

| Carbon Fiber Mirror Covers | Carbon Fiber | $150-200 | $120-160 | $100-140 | $90-130 |

| Custom Steering Wheel Cover | Genuine Leather | $120-180 | $100-150 | $80-130 | $70-100 |

| LED Ambient Lighting Kit | ABS Plastic + LEDs | $200-300 | $180-250 | $150-220 | $120-180 |

Cost Optimization Strategy:

Based on thousands of projects, my recommendation is to group similar components when ordering. For example, combining interior accessories can reduce setup costs by 25-35%. Also, consider the total lifecycle cost – investing in higher quality materials upfront often saves money on replacements later. Our engineering team can help you find the optimal balance between cost, quality, and performance for your specific project.

Common Defects & Prevention Strategies

Quality Assurance & Defect Prevention

Over 15 years in the industry, I’ve identified common failure points in custom automotive accessories. Our quality control protocols are designed to prevent these issues before they reach our customers.

Goldcattle Quality Standards

- ISO 9001 Certified: Comprehensive quality management system

- 100% Inspection: Every component undergoes dimensional and visual inspection

- Environmental Testing: Accelerated aging and weather resistance testing

- Material Verification: Batch testing for material composition and properties

Quality Guarantee:

Goldcattle comprehensive quality control processes ensure that 99.7% of our products meet or exceed customer expectations. In the rare event of a quality issue, our engineering team will work with you to resolve it quickly and completely.

Frequently Asked Questions

Lead times vary based on complexity and quantity:

Expert Note: Rushing the design phase often leads to costly reworks. I always recommend allowing adequate time for proper engineering and testing to ensure the final product meets your expectations.

We specialize in both small-batch and large-scale production:

Cost Consideration: Unit costs decrease significantly with higher volumes. For example, a custom shift knob that costs $100 for 1 unit might cost $50 for 100 units due to economies of scale in material purchasing and production setup.

When properly designed and manufactured, custom accessories can match or exceed OEM durability:

Our Guarantee: All Goldcattle custom components come with a 2-year warranty against manufacturing defects. We stand behind the quality of our products and are committed to ensuring your complete satisfaction.

This depends on the type of accessory and installation method:

- Non-invasive accessories (seat covers, floor mats, etc.)

- Exterior trim and cosmetic enhancements

- Interior storage solutions and organizers

- Performance modifications to engine or drivetrain

- Suspension and brake system changes

- Electrical system modifications

Recommendation: Consult with your dealership before making modifications that could impact critical systems. We can provide documentation for insurance and warranty purposes, including engineering specifications and installation guidelines.

EVs offer unique customization opportunities:

Tesla Specialization: We’ve developed over 50 custom accessories specifically for Tesla models, including Model 3, Model Y, Model S, and Model X. Our Tesla-specific accessories are designed to integrate seamlessly with the vehicle’s unique features and aesthetics.

on