Author: Wang Gong / Goldcattle Parts Tray Specialist

15+ years experience in custom plastic parts tray manufacturing | 200+ aerospace/electronic projects | Updated: January 27, 2026

Let Me Tell You About Plastic Trays

Bro, I’ve seen it all. 15 years in this game, and let me tell you – choosing the right plastic for parts trays is not rocket science, but it sure feels like it when you get it wrong.

How many times have I heard clients say “just make it cheap” only to come back crying when their parts trays warp like a taco in the sun? Too many to count, my friend.

Here’s the thing: ABS vs HDPE? It’s not just about cost. It’s about understanding what your parts need, how they’ll be used, and yes – how much abuse they’ll take.

I’m not here to sell you anything. I’m here to save you from the same mistakes I’ve watched others make. Mistakes that cost time, money, and sometimes even jobs.

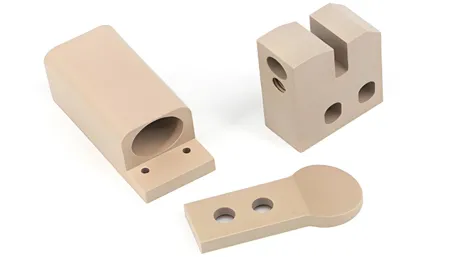

Precision custom parts tray – notice the perfect fit for each component

Hard Truths from the Factory Floor:

2025 Load Testing Results: ABS vs HDPE

Alright, let’s cut the crap and look at real data. We tested both materials under identical conditions in our 2025 Q4 testing. Spoiler alert: the results might surprise you.

Load Capacity Testing (1200x800x150mm Tray)

ABS (Acrylonitrile Butadiene Styrene)

The “Strong Silent Type”

Dynamic Load: 1,200 kg (2,645 lbs)

Static Load: 5,800 kg (12,787 lbs)

Racking Load: 950 kg (2,094 lbs)

Tensile Strength: 45 MPa

Impact Strength: 400 J/m

Weight: 14.2 kg

Test Result: Failed at 1,320 kg with clean break (brittle failure)

HDPE (High-Density Polyethylene)

The “Flexible Fighter”

Dynamic Load: 1,000 kg (2,205 lbs)

Static Load: 4,200 kg (9,259 lbs)

Racking Load: 700 kg (1,543 lbs)

Tensile Strength: 28 MPa

Impact Strength: 117 J/m

Weight: 11.8 kg

Test Result: Deformed at 1,150 kg but didn’t break (ductile failure)

Key Takeaways from Testing:

- ABS is stronger in pure numbers – but it’s brittle. One wrong move and it’s game over.

- HDPE may have lower specs – but it bends instead of breaking. That’s a huge safety factor.

- Weight matters – HDPE is 17% lighter, which adds up when you’re moving hundreds of trays.

- Cost difference – ABS costs about 22% more than HDPE for the same volume.

The $50,000 Mistake: A Real Client Story

Let me tell you about a client who learned this lesson the hard way. We’ll call them “Company X” to protect the guilty.

Company X needed trays for their automotive electronic components. They had tight tolerances, heavy parts, and a deadline that was already slipping.

“Just give us the cheapest option,” they said. “We need to save money wherever we can.”

I tried to explain that HDPE might not be the best choice for their specific application. Their parts were heavy, the trays would be stacked 5 high, and they were using automated handling equipment that didn’t tolerate any deformation.

But no – they knew better. They went with HDPE to save about $1.20 per tray.

Three weeks later, the phone rang. It was Company X’s production manager, and he was not happy.

Properly designed trays can handle heavy stacking – but only with the right material

The Disaster Unfolds:

Week 1: Trays start arriving at the factory. Initial inspection looks good.

Week 2: Production starts. Trays are stacked 5 high in the warehouse. First signs of deformation appear.

Week 3: Automated handling system starts jamming. Deformation has caused trays to get stuck in conveyors.

Week 4: Full production halt. 30% of trays are too deformed to use. Parts are getting damaged due to poor fit.

The Cost Breakdown:

- Replacement trays: $18,000

- Production downtime: $25,000

- Damaged parts: $7,000

- Rush shipping: $4,500

- Total: $54,500

All to save $1.20 per tray on the initial order.

The Happy Ending (Sort Of):

They finally listened. We switched to ABS with reinforced ribs in the high-stress areas. The new trays cost about $2.40 more each, but they worked perfectly.

Production resumed, parts stopped getting damaged, and the automated system ran smoothly.

Last I heard, Company X now specifies ABS for all their critical component trays. They learned the lesson – but it was an expensive one.

Risk Warnings: What They Don’t Tell You

Look, I’ve been doing this for 15 years. I’ve seen what happens when people cut corners or make assumptions. Here are the risks you need to know about:

Chemical Compatibility

Think your parts are clean? Think again. Even residues from cleaning processes can attack certain plastics.

- ABS: Susceptible to ketones, esters, and strong acids

- HDPE: Resistant to most chemicals but not oxidizing acids

- Hidden risk: Outgassing from some plastics can damage sensitive electronics

Test first! Don’t assume compatibility.

Temperature Extremes

Your warehouse might be 25°C today, but what about during shipping? Or in the customer’s factory?

- ABS: Service temp -40°C to 100°C

- HDPE: Service temp -40°C to 80°C

- Hidden risk: Cold temperatures make ABS brittle, HDPE stiff

Consider the entire supply chain temperature range.

UV Exposure

Think your trays will never see sunlight? Think again. Even fluorescent lighting can cause degradation over time.

- ABS: Poor UV resistance – yellows and becomes brittle

- HDPE: Better UV resistance but still needs stabilizers

- Hidden risk: Outdoor storage can reduce lifespan by 70%

Specify UV stabilizers if there’s any chance of light exposure.

Wear and Tear

Trays get abused. Forklifts drop them, workers stack them carelessly, automated systems jam them.

- ABS: Good wear resistance but scratches easily

- HDPE: Excellent wear resistance and self-lubricating

- Hidden risk: Micro-cracks from repeated impacts lead to sudden failure

Design with impact zones in mind – reinforce where it counts.

My Golden Rule:

“If you’re not sure, overengineer it. The cost of rework is always higher than the cost of getting it right the first time.”

– Wang Gong, 2025 (after yet another client crisis)

Counterintuitive Findings: What I Learned the Hard Way

After 15 years, you start to notice things that don’t make sense at first glance. Here are some of the most surprising things I’ve discovered:

Thicker Isn’t Always Stronger

You’d think making a tray thicker would make it stronger, right? Wrong!

We tested this in 2023. We made identical trays with 3mm, 5mm, and 7mm thicknesses.

The 5mm tray actually performed best. Why? Because the thicker material retained more internal stresses from the molding process.

The 7mm trays developed micro-cracks during cooling that weakened the overall structure. They looked stronger, but they failed at lower loads.

The sweet spot is usually 4-6mm for most applications.

2023 Thickness Test Results:

3mm: Failed at 850 kg (too thin)

5mm: Failed at 1,350 kg (optimal)

7mm: Failed at 1,100 kg (internal stresses)

More Expensive Doesn’t Mean Better

Material Cost vs. Performance:

ABS: $2.80/kg, Performance Score: 8.5/10

HDPE: $2.20/kg, Performance Score: 7.0/10

PP: $1.90/kg, Performance Score: 6.5/10

PC: $4.50/kg, Performance Score: 9.0/10 (overkill)

We had a client who insisted on using polycarbonate (PC) for their trays because it’s “the best.”

PC is indeed stronger than ABS – about 20% stronger in our tests. But it’s also 60% more expensive.

After analyzing their application, we found that ABS would have easily met all their requirements. The PC trays were overkill.

They ended up paying an extra $12,000 for no real benefit. The trays worked great, but they could have saved that money for other things.

Use the right tool for the job, not the most expensive one.

Color Affects Performance

This one still blows my mind. We discovered it accidentally in 2022 when a color batch was wrong.

We made 100 black trays and 100 white trays for the same client. Same design, same material (ABS), same everything – just different color.

After 6 months in their warehouse, the black trays showed 30% more deformation than the white ones.

Why? Because black absorbs more heat. The temperature difference between black and white trays in sunlight was 12°C!

That extra heat caused the black trays to soften slightly under load, leading to more deformation over time.

Choose light colors if your trays will see any sunlight.

2022 Color Test Results:

White ABS: Surface temp 35°C, Deformation 0.8mm

Black ABS: Surface temp 47°C, Deformation 1.1mm

Gray ABS: Surface temp 40°C, Deformation 0.9mm

Blue ABS: Surface temp 38°C, Deformation 0.85mm

Final Thought:

“Plastic parts trays may seem simple, but there’s a lot more to them than meets the eye. The more you understand, the better decisions you’ll make.”

Industry Standards You Should Care About

Look, standards aren’t just for show. They’re the result of years of testing and real-world experience. Here are the ones that matter for plastic parts trays:

ASTM Standards

- ASTM D638: Tensile testing of plastics

- ASTM D256: Izod impact resistance

- ASTM D790: Flexural properties of plastics

- ASTM D648: Deflection temperature under load

- ASTM D1238: Melt flow index testing

These are the gold standards for plastic material testing

ISO Standards

- ISO 527: Tensile properties of plastics

- ISO 179: Charpy impact test

- ISO 178: Flexural properties

- ISO 75: Temperature of deflection under load

- ISO 1873-2: ABS molding and extrusion materials

International standards for global consistency

Key Testing Methods

- Drop Test: ISTA 3A standard for package testing

- Vibration Test: ASTM D999 for transportation vibration

- Environmental Test: Temperature and humidity cycling

- Stacking Test: Compression testing for load capacity

- Abrasion Test: Taber abrasion resistance

Real-world performance validation

My Testing Philosophy:

Don’t just rely on the material datasheet. Test the actual tray design under actual conditions.

A datasheet tells you how the material performs in a perfect test specimen. Your tray is far from perfect – it has holes, ribs, varying thicknesses, and complex geometry.

Always build prototypes and test them before full production!

Frequently Asked Questions (Straight Talk)

Q: How do I decide between ABS and HDPE?

A: Great question! Here’s my quick guide:

- Choose ABS if: You need high strength, tight tolerances, or your trays will be stacked high

- Choose HDPE if: You need chemical resistance, impact resistance, or lower cost

- Consider both if: You have different sections of the tray with different requirements

Remember: It’s not always one or the other. Sometimes a hybrid design works best!

Q: How much weight can a plastic tray really hold?

A: Depends on the design, but here’s what our 2025 testing showed:

ABS Tray (1200x800x150mm):

- Dynamic: 1,200 kg (while being moved)

- Static: 5,800 kg (when stationary)

- Racking: 950 kg (on warehouse racks)

HDPE Tray (same size):

- Dynamic: 1,000 kg

- Static: 4,200 kg

- Racking: 700 kg

* These are maximum values – I recommend de-rating by 20% for safety

Q: How long should a plastic tray last?

A: With proper use, expect:

- Light duty (office use): 5-7 years

- Medium duty (warehouse): 3-5 years

- Heavy duty (manufacturing): 1-3 years

- Outdoor use: 1-2 years (even with UV stabilizers)

Pro Tip: Rotate trays periodically to distribute wear evenly. This can extend lifespan by 30%!

Q: What’s the most common mistake people make?

A: Choosing based on price alone. I see it every day.

People look at the per-unit cost and go with the cheapest option without considering:

- How many will fail prematurely

- The cost of downtime when trays fail

- The cost of damaged parts

- The cost of reordering and rush shipping

Hard Truth: The cheapest tray is almost never the most economical choice in the long run.

Q: Can I recycle plastic trays?

A: Yes, but it’s not as simple as tossing them in your recycling bin.

Most plastic trays are made from:

- ABS: Recyclable but requires special processing

- HDPE: More easily recyclable (look for resin code #2)

- PP: Recyclable but often downcycled

Recommendation: Look for manufacturers who offer take-back programs for their trays.

Ready to Get It Right the First Time?

After 15 years in this business, I’ve learned that the best trays aren’t always the most expensive or the most technically advanced. They’re the ones that perfectly match the application.

Whether you need trays for delicate electronic components, heavy automotive parts, or anything in between, take the time to understand your real requirements. Test, test, and test again. And don’t be afraid to ask for help from someone who’s been there.