"Why Customize Plastic Shells?"

- Standard parts cannot meet special functional requirements

- Customization enhances product competitiveness and brand value

- More cost-effective for mass production

- Professional customization ensures product quality and consistency

I. Do You Need Custom Plastic Shell Components?

Core Application Scenarios

- Product Differentiation Needs: When standard parts cannot meet unique design requirements

- Functional Requirements: Specific strength, temperature resistance, chemical resistance needed

- Mass Production: Custom molds more cost-effective for >500 unit production runs

- Brand Consistency: Unified appearance design and quality standards

Cost-Benefit Analysis

- Small Batch (<100 units): 3D printing for rapid prototyping verification

- Medium Batch (100-500 units): Consider 3D printing or simple molds

- Large Batch (>500 units): Injection molding with custom molds more economical

II. Custom Plastic Shell Component Process

Standard Customization Process

- Requirements Analysis and Design

-

- In-depth communication with customers about functional requirements

-

- 3D modeling and structural design

-

- Material selection and performance evaluation

- Prototype Production

-

- 3D printing for rapid prototype verification

-

- Functional testing and design optimization

-

- Customer confirmation and feedback

- Mold Design and Manufacturing

-

- Professional mold engineer design

-

- CNC machining and precision manufacturing

-

- Mold testing and adjustment

- Injection Molding

-

- Material preparation and process parameter setting

-

- Mass production and quality monitoring

-

- Post-processing and surface finishing

- Quality Inspection and Delivery

-

- Dimensional accuracy testing

-

- Appearance quality inspection

-

- Packaging and logistics distribution

III. Plastic Shell Materials

|

Material

|

Properties

|

Application Areas

|

|

ABS

|

High strength, impact resistant, easy to process

|

Electronic product housings, toys, home appliances

|

|

PC

|

High transparency, heat resistant, impact resistant

|

Optical components, safety protection, lighting

|

|

PP

|

Chemical resistant, heat resistant, lightweight

|

Food packaging, medical devices, automotive parts

|

|

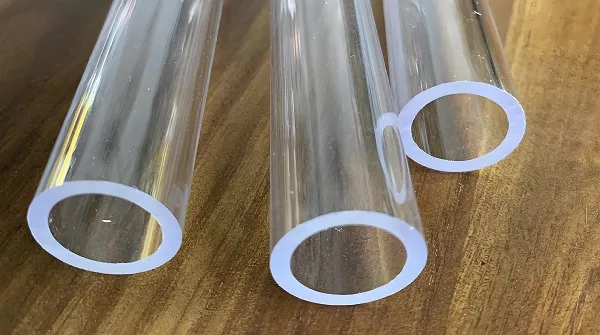

PE

|

Chemical resistant, good flexibility

|

Containers, pipes, packaging materials

|

|

PA

|

High strength, wear resistant, oil resistant

|

Mechanical parts, gears, bearings

|

|

PVC

|

Chemical resistant, flame retardant

|

Pipes, wire sheaths, industrial equipment

|

Material Selection Key Points

- Functional Requirements: Strength, heat resistance, chemical resistance

- Cost Considerations: Material price, processing difficulty

- Environmental Requirements: Food grade, medical grade certifications

- Appearance Requirements: Transparency, color stability

IV. Plastic Shell Characteristics

Main Physical Properties

- Mechanical Strength: Tensile strength, flexural strength, impact strength

- Thermal Properties: Heat resistance temperature, heat distortion temperature, thermal conductivity

- Electrical Properties: Insulation resistance, dielectric strength, arc resistance

- Chemical Properties: Corrosion resistance, solvent resistance, weather resistance

Processing Characteristics

- Flowability: Material flow ability in molds

- Shrinkage Rate: Dimensional changes during cooling

- Demoldability: Ease of removal from molds

- Machinability: Ease of cutting, drilling, surface treatment

Environmental Adaptability

- Weather Resistance: Durability for outdoor use

- Flame Retardancy: Fire resistance rating requirements

- UV Resistance: Prevention of aging and discoloration

V. Injection Molding vs. 3D Printing: Which is Better?

Technical Comparison Analysis

|

Comparison Item

|

Injection Molding

|

3D Printing

|

|

Production Volume

|

High volume (>500 units)

|

Low volume (<100 units)

|

|

Cost Structure

|

High mold cost, low unit cost

|

No mold cost, fixed unit cost

|

|

Production Speed

|

High efficiency for mass production

|

Fast for single unit production

|

|

Design Complexity

|

Limited by mold constraints

|

Freedom for complex structures

|

|

Material Selection

|

Wide range of materials

|

Limited material selection

|

|

Surface Quality

|

High surface finish

|

Requires post-processing improvement

|

|

Precision Control

|

High dimensional accuracy

|

Layer thickness affects precision

|

Selection Recommendations

- Product Development Stage: 3D printing for rapid prototype verification

- Small Batch Production: 3D printing or simple molds

- Mass Production: Injection molding

- Complex Structures: 3D printing has obvious advantages

- Functional Testing: Both processes are suitable

VI. Plastic Shell Surface Processing

Main Surface Treatment Processes

1. Painting Technology

- Process Features: Rich colors, mature technology

- Applicable Materials: ABS, PC, PP, etc.

- Advantages: High surface finish, uniform color

- Disadvantages: Higher cost, relatively lower yield rate

2. Plating Treatment

- Process Features: Metallic appearance, good conductivity

- Applicable Materials: ABS, PC, etc.

- Advantages: High-end appearance, good wear resistance

- Disadvantages: Strict environmental requirements, higher cost

3. In-Mold Decoration (IMD/IML)

- Process Features: Patterns embedded, not easily worn

- Applicable Materials: ABS, PC, etc.

- Advantages: Long-lasting patterns, advanced technology

- Disadvantages: High mold cost, difficult design changes

4. Laser Engraving

- Process Features: Permanent marking, high precision

- Applicable Materials: Various plastic materials

- Advantages: Ink-free, environmentally friendly and durable

VII. Plastic Shell Feature Processing

Functional Feature Processing

1. Strengthening Treatment

- Chemical Strengthening: Improve surface hardness and scratch resistance

- Physical Strengthening: Improve material properties through heat treatment

- Composite Strengthening: Multi-layer structure enhances overall performance

2. Functional Coatings

- Anti-Fingerprint Coating: Reduce fingerprint residue, easy to clean

- Antibacterial Coating: Inhibit bacterial growth, suitable for medical equipment

- Conductive Coating: Achieve electromagnetic shielding function

- Hydrophobic Coating: Waterproof and moisture-proof, protect internal components

3. Structural Optimization

- Reinforcement Rib Design: Improve structural strength

- Weight Reduction Design: Optimize material distribution, reduce weight

- Heat Dissipation Design: Improve thermal conductivity

Safety Features

- Flame Retardant Treatment: Improve fire resistance rating

- Impact Resistance Design: Absorb impact energy

- Environmental Certification: Meet RoHS, REACH and other standards

VIII. Plastic Shell Color Processing

Color Processing Methods

1. Masterbatch Coloring

- Process Features: Good uniformity, stable color

- Applicable Scope: Mass production

- Advantages: High color consistency, relatively low cost

- Disadvantages: Long color change time, not economical for small batches

2. Surface Painting

- Process Features: Rich color selection, can achieve gradient effects

- Applicable Scope: Various production volumes

- Advantages: Diverse color effects, can be partially colored

- Disadvantages: Coating may peel off, need to pay attention to adhesion

3. In-Mold Coloring

- Process Features: Color integrated with substrate, never fades

- Applicable Scope: Products with special color requirements

- Advantages: Long-lasting color, good wear resistance

- Disadvantages: Limited material selection, higher cost

4. Two-Color Injection Molding

- Process Features: Two colors integrated molding

- Applicable Scope: Products requiring two-color effects

- Advantages: Strong structure, exquisite appearance

- Disadvantages: Complex molds, higher cost

Color Management

- Color Difference Control: Use color difference meter for precise control

- Batch Management: Ensure color consistency across different batches

- Environmental Testing: Verify color stability

IX. How to Choose the Right Plastic Shell?

Selection Consideration Factors

1. Functional Requirements Analysis

- Usage Environment: Temperature, humidity, chemical contact

- Mechanical Requirements: Strength, rigidity, impact resistance

- Electrical Requirements: Insulation, electromagnetic shielding

- Appearance Requirements: Transparency, color, surface texture

2. Cost-Benefit Evaluation

- Material Cost: Price differences between different materials

- Processing Cost: Injection molding vs. 3D printing

- Mold Cost: Mold opening costs vs. production volume

- Maintenance Cost: Long-term usage maintenance costs

3. Quality Standard Considerations

- Dimensional Accuracy: Tolerance requirements and measurement methods

- Surface Quality: Finish, flatness requirements

- Performance Testing: Meet relevant industry standards

- Reliability: Service life and failure rate

4. Supply Chain Evaluation

- Supplier Capability: Technical level, equipment conditions

- Delivery Cycle: Time from design to delivery

- Service Quality: Technical support and after-sales service

- Sustainability: Environmental protection measures and social responsibility

Professional Recommendations

- Prototype Verification: Make samples for testing first

- Multi-Solution Comparison: Evaluate different design options

- Long-Term Cooperation: Choose reliable suppliers for long-term partnerships

X. Common Plastic Shell Processing Issues

Injection Molding Issues

1. Surface Defects

- Sink Marks: Depressions caused by uneven material shrinkage

- Air Bubbles: Moisture in material or poor venting

- Flow Marks: Streaks formed by uneven melt flow

- Burn Marks: Material decomposition due to local overheating

2. Dimensional Issues

- Dimensional Deviation: Improper mold precision or process parameters

- Warping: Uneven cooling or structural design issues

- Flash: Poor mold clamping or excessive injection pressure

3. Structural Issues

- Short Shots: Insufficient injection volume or poor flowability

- Weld Lines: Reduced strength at melt merge areas

- Distortion: Uneven cooling shrinkage

3D Printing Issues

- Poor Layer Adhesion: Affects overall strength

- Surface Roughness: Requires post-processing improvement

- Dimensional Accuracy: Affected by equipment and materials

Solutions

- Process Optimization: Adjust temperature, pressure, speed parameters

- Mold Improvement: Optimize gate, cooling system design

- Material Selection: Replace with more suitable materials

- Equipment Maintenance: Regular maintenance to ensure equipment precision

Professional Service Recommendation

Core Advantages

- Technical Strength: ±0.005mm ultra-high precision control

- Advanced Equipment: Over 100 precision processing machines

- Quality Assurance: International certifications including SGS, RoHS, CE

- Service Scope: Multiple industries including automotive, machinery, electronics, medical

Service Process

- Requirements Communication: Understand your specific requirements

- Solution Design: Provide professional technical solutions

- Prototype Production: Rapid prototype production to verify design

- Mass Production: Efficient and high-quality production services

- Quality Inspection: Strict quality control system

- Delivery Service: On-time delivery and after-sales service

Contact Us Now for Professional Solutions!

Contact Information

- Technical Consultation: One-on-one service from professional engineers

- Quick Quotation: Detailed quotation within 24 hours

- Sample Production: Rapid sample production to verify design

- Mass Production: Efficient and high-quality mass production capabilities