I. Core Material Properties and Application Advantages

(A) Comparison of Mainstream Material Properties

|

Material Type

|

Density (g/cm³)

|

Temperature Range (℃)

|

Core Advantages

|

Typical Certifications

|

|

Acrylonitrile Butadiene Styrene (ABS)

|

1.03–1.07

|

-20 to 80

|

Easy moldability, high toughness, cost-effective

|

UL94 V-0 Flame Retardant Certification

|

|

Polycarbonate (PC)

|

1.20–1.22

|

-40 to 130

|

Impact resistance, high transparency, dimensional stability

|

UL746C Material Certification

|

|

Polyphenylene Oxide (PPO)

|

1.06–1.07

|

-40 to 155

|

Excellent insulation, chemical corrosion resistance

|

UL94 V-1 Flame Retardant Certification

|

|

Polybutylene Terephthalate (PBT)

|

1.31–1.53

|

-40 to 150

|

Low hygroscopicity, high abrasion resistance

|

IEC 60243 Dielectric Strength Certification

|

|

PC/ABS Alloy

|

1.12–1.20

|

-30 to 120

|

Balanced high strength and toughness

|

RoHS Environmental Certification

|

(B) Driving Forces of Customization Requirements

1. Safety Performance

- Flame retardancy rating must reach UL94 V-0 (1.6mm thickness), passing glow wire test (850℃) without ignition.

- Insulation resistance ≥ 10¹²Ω (500V test voltage), dielectric strength ≥ 25kV/mm.

2. Heat Dissipation and Structure

- Heat dissipation hole opening rate ≥ 30%, air resistance coefficient ≤ 0.3 (optimized via CFD simulation).

- Positioning accuracy of 卡扣 /screw holes ±0.1mm for precise assembly with internal power components.

3. Environmental Adaptability

- Thermal shock resistance (-20℃ to 70℃ cycling 50 times without cracking), suitable for complex working conditions.

- Antistatic surface treatment (surface resistance ≤ 10⁹Ω) to reduce dust adsorption.

II. Analysis of Four Core Processing Technologies

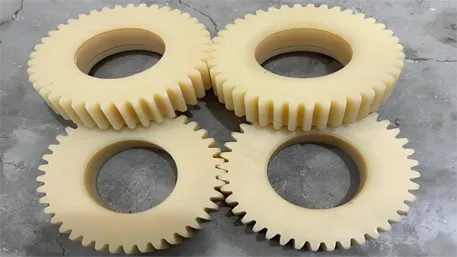

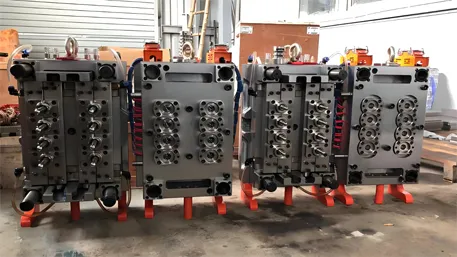

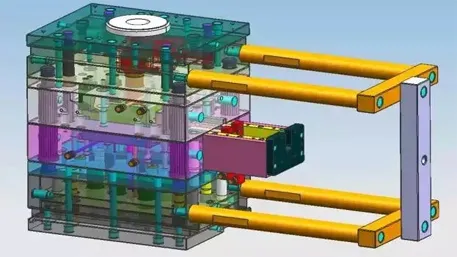

(A) Injection Molding: High-Precision Structural Processing

- Technical Advantages:

-

- Enables one-step molding of complex structures (e.g., heat dissipation grilles, mounting bosses) with dimensional accuracy ±0.05mm.

-

- Large-scale mold design (1–4 cavities per mold), suitable for 500–2000g power supply cases, production efficiency 500–1000 pieces/hour.

- Process Parameters:

-

- Injection pressure 120–180MPa, mold temperature 60–100℃, cooling time 20–30 seconds.

-

- Shrinkage control: 0.4%–0.7% for ABS, 0.5%–0.8% for PC/ABS, ensuring assembly tolerance ≤0.03mm.

(B) In-Mold Decoration (IMD): Integration of Appearance and Function

|

Process Type

|

Typical Application Scenarios

|

Technical Highlights

|

|

Texture Molding

|

Matte/brushed surfaces for high-end cases

|

Mold surface roughness Ra≤0.2μm, gloss control 40–60GU (60° angle)

|

|

Composite Molding

|

Transparent windows + main structure

|

Optical-grade PC with light transmittance ≥90%, bonding strength with ABS ≥15MPa

|

- Technical Advantages:

-

- Paint-free process reduces VOC emissions, meeting environmental requirements.

-

- Surface hardness ≥3H, passing 500-cycle friction test without scratches.

(C) 3D Printing: Rapid Prototyping and Small-Batch Customization

- Process Advantages:

-

- Quickly validates irregular structures (e.g., curved heat holes, modular clips), with samples delivered in 3 days.

-

- Nylon 12CF material strength up to 180MPa, suitable for high-strength prototype testing.

- Application Scenarios:

-

- Custom server power supply cases (order quantity ≤500 pieces), delivery cycle reduced by 40%.

-

- Personalized hole design for modular power supply cases.

(D) Surface Treatment Technologies

- Flame Retardancy Enhancement:

-

- Nano-scale flame retardant modification (5%–10% additive), upgrading flame retardancy to UL94 V-0.

-

- Fire-resistant coating (50–100μm thickness), oxygen index ≥28%.

- Heat Dissipation Optimization:

-

- Metallized coating (20–30μm aluminum-based), thermal conductivity increased to 1.2W/(m·K).

-

- Micro-structured design (heat fins 3–5mm height, 2–3mm spacing), heat dissipation efficiency improved by 20%.

III. Full-Process Customization Solutions

(A) Design and Material Engineering

- Multi-Dimensional Design Support:

-

- Structural Optimization: ANSYS simulation analyzes clip stress distribution to ensure 1000-time disassembly without fracture.

-

- Functional Customization:

-

-

- Modular power supply cases: Support quick-release structure (disassembly time ≤30 seconds), adaptable to different power modules.

-

-

-

- Noise reduction design: Muffling structure for heat holes (5–8mm diameter, 15°–20° angle), noise reduction by 5–8dB.

-

- Precise Material Selection:

-

- Consumer-grade power supplies: ABS + 20% flame retardant, meeting UL94 V-0 standards with 15% cost reduction.

-

- Industrial-grade power supplies: PPO material, volume resistivity ≥10¹⁶Ω·cm, suitable for high-humidity environments (humidity ≤95%RH).

- Pre-Processing Technology:

-

- Raw material drying: PC moisture content controlled ≤0.02% to avoid molding bubbles.

-

- Antistatic treatment: Permanent antistatic agents added (surface resistance ≤10⁸Ω), suitable for precision electronic environments.

(B) Production and Quality Control

- Flexible Manufacturing Capability:

-

- Rapid Prototyping: 3D printed samples delivered in 48 hours, aluminum mold development cycle 10–15 days (steel mold 30–45 days).

-

- Mass Production:

-

-

- High-speed injection lines: Equipped with KUKA robots, daily output 3000 pieces per machine (2-cavity mold).

-

-

-

- Automated production lines: Integrated visual inspection system, appearance defect recognition rate ≥99.5%.

-

- Comprehensive Testing System:

-

- Electrical Performance:

-

-

- Dielectric withstand test: 2000V AC for 1 minute without breakdown, leakage current ≤0.5mA.

-

-

-

- Insulation resistance: 500V DC test, resistance value ≥10¹³Ω.

-

-

- Mechanical Performance:

-

-

- Drop test: 1.2m drop to concrete, breakage rate ≤1% (100-piece sample).

-

-

-

- Aging test: QUV-A irradiation for 1000 hours, color difference ΔE≤2, strength retention ≥90%.

-

-

- Certification Support: Provides UL, CE, CB, and other international certification reports for global market access.

IV. Multi-Scenario Application Solutions

(A) Consumer Electronics

- ATX Power Supply Cases: PC/ABS alloy material, supporting side-transparent window design (transmittance ≥85%), UV coating for anti-yellowing (color difference ΔE≤3 after 3 years).

- Laptop Adapter Cases: Thin-wall design (1.2–1.5mm thickness), passing 1.5m drop test, 20% lighter than traditional designs.

(B) Industrial Equipment

- Server Power Supply Cases: PBT + 30% glass fiber, resistant to 120℃ long-term operation, dustproof grade IP54 (dust ingress ≤1g/m³).

- Automation Equipment Power Cases: PPO material + metal inserts, EMI shielding efficiency ≥40dB, suitable for industrial control environments.

(C) New Energy Sector

- Energy Storage Power Cases: Fire-resistant PC material, UL94 V-0 certified, supporting IP65 waterproof design (1m water immersion for 30 minutes without water ingress).

- Vehicle Power Cases: Low-temperature modified ABS (-40℃ impact strength ≥25kJ/m²), adapted to vehicle vibration environments (10–2000Hz frequency, acceleration ≤5g).

V. Technology Selection Guide

|

Requirement Type

|

Preferred Technology

|

Weight Range

|

Core Indicators

|

Delivery Cycle

|

|

R&D Validation & Small Batches

|

3D Printing + Injection Molding

|

200–1000g

|

Rapid iteration, structural validation

|

Prototype in 3 days, batch in 15 days

|

|

High-End Appearance & Heat Dissipation

|

IMD + PC/ABS

|

500–1500g

|

High flame retardancy, low noise, premium aesthetics

|

Prototype in 7 days, batch in 25 days

|

|

Large-Scale Standardized Production

|

Injection Molding + ABS

|

800–2000g

|

Low cost, high reliability

|

Prototype in 5 days, batch in 20 days

|