In the booming plastic products market, custom PVC plastic parts have become the core choice for more than 20 industries, such as construction, electronics, and healthcare, thanks to their excellent comprehensive performance and flexible customization advantages. In 2023, the global market size of PVC plastic parts exceeded $50 billion, with an annual growth rate of 6.8%. This data confirms their broad application prospects and strong market demand.

I. Core Advantages of PVC Materials

- Exceptional Chemical Stability: It can withstand sulfuric acid with a concentration of up to 90% and hydrochloric acid with a concentration of up to 30%. In chemical pipeline applications, its service life can reach 15 – 20 years, three times that of ordinary plastics.

- Outstanding Flame Retardancy: Meeting the UL94 V-0 flame retardant standard, with a self-extinguishing time of ≤5 seconds after the fire source is removed. When used for electronic appliance casings, it reduces the fire risk by more than 60%.

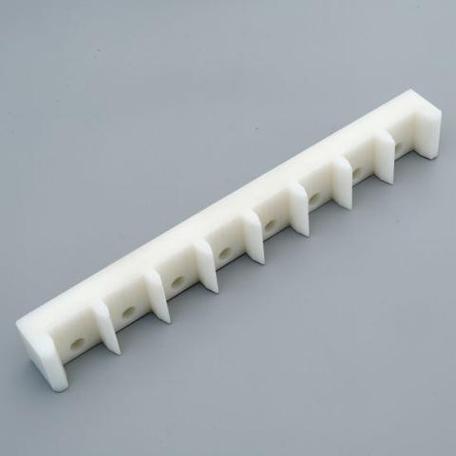

- Flexible Processing Adaptability: It supports various molding processes such as injection molding, extrusion, and blow molding. The shortest mold forming cycle is only 8 seconds. Using a 64-cavity mold can increase production efficiency by 300%.

II. Full Process of Customization Services

- Requirement Communication: Respond to requirements within 24 hours. Utilize 3D scanning and AI modeling technologies to quickly confirm the design plan.

- Mold Manufacturing: Achieve a mold accuracy of ±0.005mm through five-axis machining centers, supporting the production of ultra-thin parts with a thickness of 0.3mm.

- Intelligent Production: An automated production line, combined with a PLC control system, keeps the defective rate within 0.3%.

- Quality Inspection and Delivery: Conduct 100% dimensional inspection and obtain third-party certification. Regular orders are delivered within 7 – 15 days, and a 3-day rush service is available.

III. In-depth Technical Analysis

(I) Material Modification Technologies

- Anti-aging Modification: By adding nano-scale UV absorbers and antioxidants, the weather resistance of PVC plastic parts in outdoor environments is increased by 40%, making them suitable for applications such as building window profiles and outdoor signage.

- Toughening and Reinforcement Modification: Incorporating MBS (Methyl Methacrylate-Butadiene-Styrene Copolymer) or glass fibers increases the impact strength by 35% and the flexural strength by 25%, meeting the high-strength requirements of automotive interior parts and industrial equipment casings.

- Antibacterial Modification: Using silver ion antibacterial technology, it achieves an antibacterial rate of 99% against Escherichia coli and Staphylococcus aureus, commonly used for products with strict hygiene requirements, such as medical trays and food-grade containers.

(II) Precision Molding Process Optimization

- Precise Temperature Control: Employ a segmented temperature control system, with the front section of the barrel at 160 – 170°C, the middle section at 170 – 180°C, and the rear section at 150 – 160°C. Combined with the dynamic adjustment of the mold temperature between 40 – 60°C, it ensures uniform plasticization of the PVC melt, reduces decomposition risks, and improves molding quality.

- Dynamic Pressure Management: Adopt a servo hydraulic system to adjust pressure parameters in real-time according to products of different wall thicknesses. For thin-walled parts (wall thickness ≤1mm), the injection pressure is maintained at 80 – 100MPa; for thick-walled parts (wall thickness ≥3mm), the injection pressure is adjusted to 60 – 80MPa. The holding pressure is set at 60% – 70% of the injection pressure, enabling dimensional accuracy control within ±0.05mm.

- Efficient Time Optimization: Optimize the layout of the cooling water channels through mold flow analysis. Combined with precise temperature control by the mold temperature controller, the proportion of cooling time is reduced from 70% in traditional processes to 60%. For example, in the production of ordinary PVC pipe fittings, the molding cycle is reduced from 25 seconds to 18 seconds, significantly improving production efficiency.

(III) Advanced Mold Design and Manufacturing Technologies

1. Innovative Design Concepts and Processes

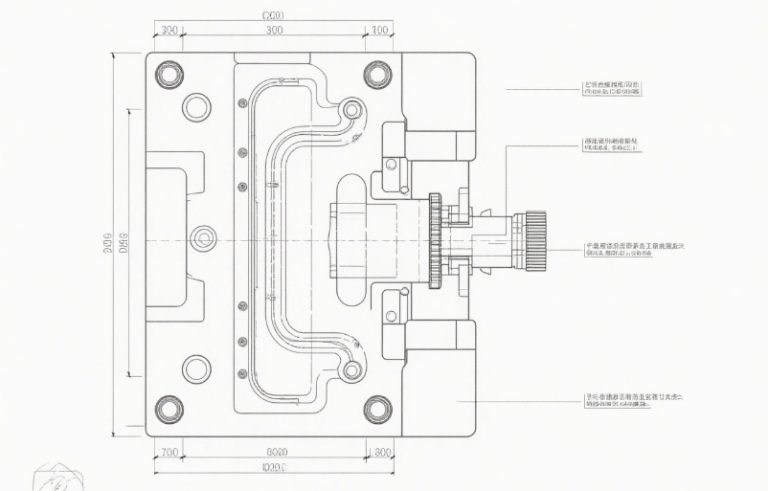

Mold design is the key starting point for the production of custom PVC plastic parts. We adopt a dual-track mode of “data-driven + experience verification”. First, based on the product design drawings or 3D models provided by customers, we use CAD/CAM software (such as UG NX, SolidWorks) to perform 1:1 digital modeling, accurately restoring product details. At the same time, considering the shrinkage rate characteristics of PVC materials (usually 0.1% – 0.5%), pre-compensation is carried out for the dimensions of the mold cavity to ensure the dimensional accuracy of the molded products.

During the design stage, Moldflow mold flow analysis software is used for multiple rounds of simulation. By simulating parameters such as the flow path, filling time, pressure distribution, and cooling rate of the PVC melt in the mold, potential defects such as weld lines, air traps, and warpage can be predicted in advance. For example, when designing molds for complex-structured automotive interiors, optimizing the gate position through mold flow analysis transfers the weld lines to non-appearance surfaces, increasing the product yield from 78% to over 95%. In addition, for multi-cavity mold design, a balanced runner system is adopted to ensure uniform melt filling in each cavity and reduce dimensional deviations caused by unbalanced filling.

2. Key Technologies and Processes

- Hot Runner Technology: The hot runner system is widely applied in mold design, especially for large or multi-cavity molds. Hot runner technology keeps the PVC melt in the runner in a molten state through heating, avoiding the generation of a large amount of sprue waste in traditional cold runners. For example, when producing 100,000 PVC electrical appliance casings, using a hot runner mold can reduce material waste by 30% and shorten the molding cycle by 15%, significantly reducing production costs.

- Slider and Angle Lifter Mechanisms: For PVC plastic parts with side holes, side recesses, or undercuts, slider or angle lifter core-pulling mechanisms are designed. These mechanisms achieve lateral core-pulling through the opening and closing actions of the mold, ensuring smooth product demolding. For example, when manufacturing molds for PVC pipe fittings with side holes, the design accuracy of the slider mechanism is controlled within ±0.01mm, ensuring accurate side hole positions without burrs and meeting product assembly requirements.

- Cooling System Optimization: An efficient cooling system is crucial for shortening the molding cycle and ensuring product quality. We adopt the design concept of “conformal cooling” and use 3D printing technology to create cooling water channels that vary with the product shape, making mold cooling more uniform. Compared with traditional straight-hole cooling, conformal cooling can reduce the average mold cooling time by 25% – 30%. For example, in the production of large-scale PVC sheet molds, the conformal cooling system reduces the cooling time from 20 seconds to 14 seconds, greatly improving production efficiency.

3. Precision Manufacturing Process

The mold manufacturing process follows a standardized sequence of “rough machining – semi-finishing – finishing – surface treatment”. In the rough machining stage, high-speed milling equipment is used to quickly remove most of the material, leaving a machining allowance of 0.5 – 1mm. The semi-finishing process further refines the mold structure, with an accuracy controlled within ±0.05mm. In the finishing stage, five-axis 联动 machining centers and electrical discharge machining (EDM) technology are employed to achieve ultra-high precision machining within ±0.005mm, ensuring the dimensional and surface quality of the mold cavity and core. For molds requiring a mirror finish, polishing treatment is also required to make the surface roughness of the mold cavity reach below Ra0.4μm, thus producing PVC transparent parts with a light transmittance of over 88%.

4. Mold Material Selection

Mold materials are selected rationally according to the production batch, product requirements, and molding process of PVC plastic parts. For small-batch production or mold trials, P20 pre-hardened steel is used. With a hardness of HRC30 – 35, it has good machining performance and certain wear resistance. For large-batch production molds, S136 mirror stainless steel or NAK80 high-hardness pre-hardened steel is preferred. S136 steel has excellent corrosion resistance and mirror polishing performance, suitable for manufacturing molds for medical-grade and food-grade PVC products. NAK80 steel has a high hardness of HRC38 – 41, meeting high wear resistance requirements without the need for heat treatment. It also has good electrical discharge machining performance and can be used to manufacture molds with complex structures.

5. Technological Upgrades and Intelligent Applications

Mold intelligent manufacturing technologies are introduced. IoT sensors are used to monitor data such as mold temperature, pressure, and wear in real-time, and the data is fed back to the central control system. When abnormalities occur in the mold, the system automatically alarms and provides maintenance suggestions, effectively preventing mold failures and extending the mold service life. At the same time, digital twin technology is utilized to construct a virtual mold model, which synchronously simulates the actual production process, further optimizing mold design and process parameters and achieving full-process digitalization and intelligence from design to manufacturing.

(IV) Application of Cutting-edge Processing Technologies

- Microcellular Foam Injection Molding Technology: Injecting supercritical carbon dioxide to form a microcellular structure reduces the product density by 15% – 25%. While reducing weight, it maintains mechanical properties, widely used in automotive interiors and electronic device casings to reduce transportation costs and energy consumption.

- Two-color/Multi-color Injection Molding Technology: Through two-color injection molding machines, composite molding of PVC with other materials such as TPU and ABS is achieved, completing the production of different color and performance areas in one injection. For example, tool casings combine a rigid PVC body with a soft TPU grip, taking into account both strength and grip comfort.

- Micro Injection Molding Technology: For precision micro parts, high-precision screws and nozzles are used, with a minimum injection volume of up to 0.01g, suitable for the production of millimeter-scale components such as medical catheter connectors and electronic connectors.

(V) Intelligent Production and Quality Control

- Intelligent Production System: Equipped with servo-electric injection molding machines with a clamping force of 1000 – 5000 tons, integrated with a PLC control system, it enables real-time monitoring and automatic adjustment of parameters such as temperature, pressure, and speed. Through the linkage of the mold temperature controller, robotic arms, and conveyor belts, an automated production line is constructed, reducing the energy consumption per piece by 25%.

- Comprehensive Quality Inspection Guarantee: Implement the ISO 9001 quality management system. Use coordinate measuring machines (accuracy ±0.01mm) and two-dimensional image measuring instruments for 100% dimensional inspection. Conduct more than 20 inspection items, including 200-hour aging tests, salt spray tests, and flame retardancy tests, and provide third-party inspection reports.

IV. Application Cases in Multiple Industries

| Industry | Product Type | Customization Advantages |

|---|---|---|

| Construction | Drainage pipes, window profiles | Weather resistance increased by 40%, cost reduced by 18% |

| Electronics | Socket casings, data cable protective sleeves | Insulation strength up to 15kV/mm, temperature resistance from -20°C to 70°C |

| Medical | Infusion tubes, medical trays | Compliant with ISO 10993 biocompatibility standards |

| Automotive | Interior clips, wire harness sleeves | Weight reduced by 20%, impact resistance increased by 35% |

| Food Packaging | Food containers, boxes | Antibacterial rate of 99%, compliant with FDA food contact standards |

V. Cost-effective and Efficient Solutions

- Economies of Scale for Cost Control: The minimum order quantity is as low as 500 pieces. Unit prices for bulk orders can be reduced by 20% – 35%.

- Express Delivery Guarantee: Regular orders are delivered within 7 – 15 days. A 3-day rush delivery channel is available for urgent orders.

- Full-cycle Service Support: Free design optimization, mold maintenance, and product iteration upgrade services are provided.

VI. Frequently Asked Questions

- What is the minimum order quantity for customization? The minimum order quantity for standard parts is 500 pieces, and it can be negotiated for complex parts.

- What is the fastest delivery cycle? Urgent orders can be delivered within 3 days, and regular orders are delivered within 7 – 15 days.

- How is quality guaranteed? We are certified by ISO 9001, and defective products are replaced free of charge.

If you have requirements for custom PVC plastic parts or any questions regarding technical details and product applications, please feel free to leave a comment! Our technical team will respond within 24 hours, providing you with free design solutions and professional technical answers to help your project be implemented efficiently!