I. Core Material Properties and Application Advantages

(A) Comparison of Mainstream Material Properties

|

Material Type

|

Density (g/cm³)

|

Temperature Range (℃)

|

Core Advantages

|

Typical Certifications

|

|

Polypropylene (PP)

|

0.89–0.91

|

-30 to 120

|

Moist-heat resistance, chemical corrosion resistance, cost-effective

|

LFGB Food Contact Certification

|

|

Acrylonitrile Butadiene Styrene (ABS)

|

1.03–1.07

|

-20 to 80

|

High toughness, easy moldability, easy electroplating

|

UL94 V-0 Flame Retardant Certification

|

|

Polybutylene Terephthalate (PBT)

|

1.31–1.53

|

-40 to 150

|

Low hygroscopicity, high abrasion resistance

|

IEC 60243 Dielectric Strength Certification

|

|

PC/ABS Alloy

|

1.12–1.20

|

-30 to 120

|

Balanced high strength and temperature resistance

|

RoHS Environmental Certification

|

|

Glass Fiber Reinforced Polypropylene (PP+GF)

|

1.05–1.15

|

-20 to 130

|

High rigidity, fatigue resistance

|

ISO 16750-3 Chemical Resistance Test

|

(B) Driving Forces of Customization Requirements

1. Environmental Adaptability

- Moist-Heat Resistance: No deformation after 500 hours in 90%RH/50℃ environment, tensile strength retention ≥80%.

- Detergent Resistance: Swelling rate ≤1.5% after 72-hour immersion in 5% laundry liquid, no surface cracking.

2. Structural Reliability

- Load-Bearing Capacity: Inner tub components must withstand ≥50kg dynamic load (simulating full-load washing conditions), deformation ≤1mm.

- Assembly Precision: Positioning accuracy of clips/screw holes ±0.1mm, ensuring assembly gap with metal frames ≤0.3mm.

3. Functional Adaptability

- Sealing Performance: Waterproof grade IPX4 for sealing components, no leakage under 20kPa pressure test.

- Control Panel Requirements: Weather resistance (QUV-A irradiation 1000 hours, color difference ΔE ≤3), surface hardness ≥2H.

II. Analysis of Four Core Processing Technologies

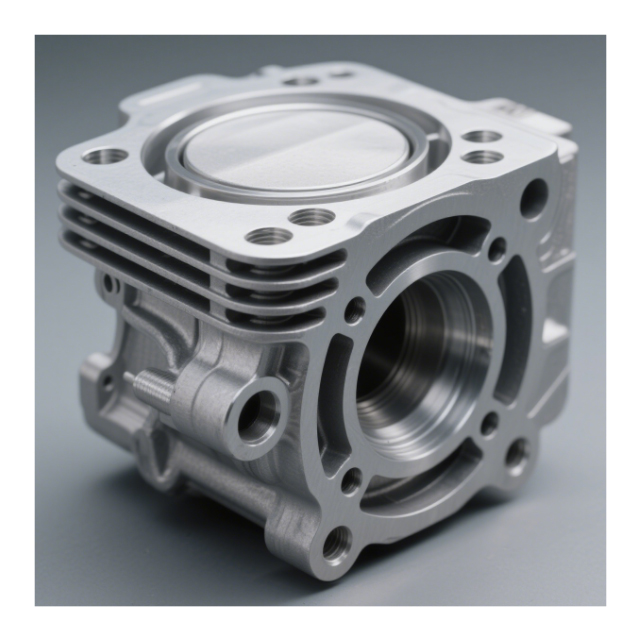

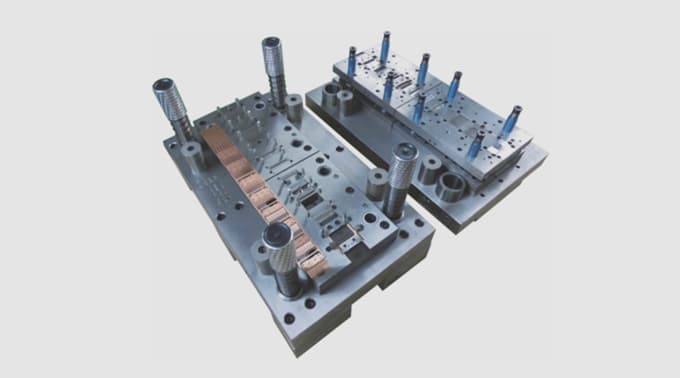

(A) Injection Molding: High-Precision Structural Processing

- Technical Advantages:

-

- Enables one-step molding of complex rib structures (e.g., inner tub supports), dimensional accuracy ±0.05mm.

-

- Multi-cavity mold design (8–16 cavities per mold), suitable for 50–1000g parts, production efficiency 800–2000 pieces/hour.

- Process Parameters:

-

- Injection pressure 120–180MPa, mold temperature 50–80℃, cooling time 15–25 seconds.

-

- Shrinkage control: 1.2%–1.8% for PP, 0.8%–1.2% for PBT, ensuring assembly tolerance ≤0.03mm.

(B) Blow Molding: Custom Hollow Component Production

|

Process Type

|

Typical Application Scenarios

|

Technical Highlights

|

|

Extrusion Blow Molding

|

Washing machine inner tubs, balance rings

|

Wall thickness uniformity ≥95%, maximum diameter ≤1000mm

|

|

Injection Blow Molding

|

Transparent observation windows, water inlet pipes

|

Optical-grade precision (transmittance ≥90%), interface accuracy ±0.02mm

|

- Technical Advantages:

-

- Multi-layer co-extrusion combines wear-resistant (PP) and UV-resistant (PE) layers, extending service life by 40%.

-

- Inner tub roundness error ≤0.5mm, ensuring drum rotation balance (vibration amplitude ≤1.5mm).

(C) Surface Treatment Technologies

- Functional Coatings:

-

- Antibacterial Treatment: Silver-ion coating (bacteriostasis rate ≥99.9%), suitable for bacteria-prone components like inner tubs and filters.

-

- Detergent-Resistant Coating: Teflon coating (20–30μm thickness), surface tension ≤18mN/m, reducing foam residue.

- Decorative Treatments:

-

- Electroplating: Chrome layer thickness 8–12μm, salt spray test ≥1000 hours, enhancing control panel metallic texture.

-

- Matte Treatment: Surface roughness Ra 1.6–3.2μm, fingerprint resistance (cleaning cycle extended by 50%).

(D) 3D Printing: Rapid Prototyping & Small-Batch Customization

- Process Advantages:

-

- Quickly validates irregular structures (e.g., wave-shaped inner tub walls, clip-on filters), samples delivered in 3 days.

-

- Nylon 12 material strength up to 80MPa, suitable for load-bearing prototype testing.

- Application Scenarios:

-

- Custom high-end model parts (order quantity ≤300 pieces), delivery cycle reduced by 40%.

-

- Reverse engineering for obsolete model parts (3D scanning modeling error ≤0.1mm).

III. Full-Process Customization Solutions

(A) Design and Material Engineering

- Multi-Dimensional Design Support:

-

- Structural Optimization:

-

-

- Inner tub reinforcing ribs at 8–10 ribs/100mm, reducing stress concentration via ANSYS simulation, fatigue life increased by 30%.

-

-

-

- Seal ring lip angle designed at 45°±5°, ensuring dynamic sealing pressure ≥5kPa.

-

-

- Functional Customization:

-

-

- Self-cleaning inner tub: 0.5mm-depth flow channels on inner wall, reducing foam residue by 60%.

-

-

-

- Anti-vibration foot pads: TPU soft rubber + PP hard plastic composite molding, vibration absorption efficiency ≥70% (10–100Hz frequency band).

-

- Precise Material Selection:

-

- Inner Tub & Load-Bearing Parts: PP+30%GF material, bending strength ≥50MPa, adapted to long-term moist-heat environments (water absorption ≤0.05%).

-

- Control Panel: PC/ABS alloy, transmittance ≥85% (indicator area), surface scratch resistance (3H hardness).

- Pre-Processing Technology:

-

- Raw material drying: PBT moisture content controlled ≤0.03% to avoid post-molding hydrolysis cracking.

-

- Color matching: Pantone color accuracy ΔE ≤1.0, supporting custom brand-specific gray tones (L* 40–60, a±5, b±5).

(B) Production and Quality Control

- Flexible Manufacturing Capability:

-

- Rapid Prototyping: 3D printed samples delivered in 48 hours, aluminum mold development cycle 10–15 days (steel mold 35–45 days).

-

- Mass Production:

-

-

- High-speed injection lines: Equipped with Kawasaki robots, daily output 10,000 pieces per machine (16-cavity mold).

-

-

-

- Automated production lines: Integrated visual inspection system, inner tub wall thickness detection accuracy ±0.1mm, defect recognition rate ≥99.5%.

-

- Comprehensive Testing System:

-

- Physical Properties:

-

-

- Load-bearing test: Inner tub loaded with 50kg for 24 hours, diameter deformation ≤0.2%.

-

-

-

- Impact test: 500g steel ball drop from 1m height at -20℃, no surface cracks.

-

-

- Environmental Performance:

-

-

- Moist-heat test: 50℃/95%RH environment for 1000 hours, tensile strength retention ≥75%.

-

-

-

- Detergent resistance test: 10% laundry liquid cyclic flushing 500 times, no swelling or discoloration.

-

-

- Certification Support: Provides GB 4706, CE, ETL, and other certification reports for global market access.

IV. Multi-Scenario Application Solutions

(A) Core Structural Components

- Drum Inner Tub: PP+GF blow-molded, inner wall smoothness Ra≤0.8μm, dynamic balance error ≤5g·cm, adapted for 10–12kg washing capacity.

- Impeller Turntable: Wear-resistant PBT injection-molded, tooth depth 1.5mm, torque transmission efficiency ≥90%, anti-cloth entanglement design.

(B) Functional Parts

- Water Inlet Valve Housing: High-pressure resistant PP, withstanding 1.6MPa water pressure without leakage, compatible with 3/4″ and 1/2″ interfaces (tolerance ±0.05mm).

- Filter: Antibacterial ABS material, filter mesh aperture 0.5mm, clip-on design for disassembly in ≤15 seconds, impurity interception rate ≥95%.

(C) Appearance & Control Components

- Operation Panel: IMD-processed PC/ABS panel, integrated touch buttons (response time ≤5ms), anti-misoperation edge design (chamfer R≥3mm).

- Outer Side Panels: Matte PP material, surface roughness Ra 2.5μm, anti-fingerprint treatment, scratch hiding ability improved by 40%.

(D) High-End Model Customization

- Quiet Washing Machine Parts: Inner tub balance ring with liquid silicone-filled PP housing, vibration noise ≤48dB (washing mode), dynamic balance accuracy grade G2.5.

- Bacteria-Removing Inner Tub: Nano-silver ion-modified PP material, bacteria removal rate ≥99.9% during 60℃ high-temperature washing, compliant with GB 21551.4 standards.

V. Technology Selection Guide

|

Requirement Type

|

Preferred Technology

|

Weight Range

|

Core Indicators

|

Delivery Cycle

|

|

R&D Validation & Small Batches

|

3D Printing + Injection Molding

|

50–500g

|

Rapid iteration, irregular structures

|

Prototype in 3 days, batch in 15 days

|

|

Moist-Heat Resistant Load-Bearing Parts

|

Blow Molding + PP+GF

|

500–2000g

|

High rigidity, hydrolysis resistance

|

Prototype in 7 days, batch in 25 days

|

|

Large-Scale Standardized Production

|

Injection Molding + PP

|

100–1000g

|

Low cost, high chemical resistance

|

Prototype in 5 days, batch in 20 days

|