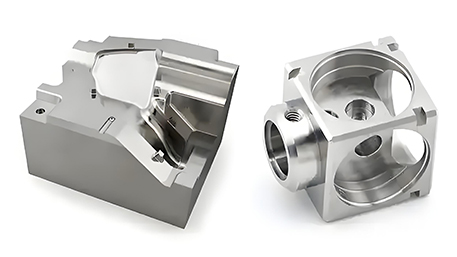

Alloy Precision Machined Parts are parts made from alloy materials through high-precision machining technology. These parts are widely used in aerospace, medical equipment, precision instruments, automobile manufacturing and many other fields due to their high precision, high strength and good corrosion resistance. Alloy precision machined parts not only require excellent performance of the material itself, but also need to have accurate size and shape to meet the requirements of complex mechanical systems.

1.Alloy precision machined parts production process

Material preparation: according to the design requirements, select suitable alloy materials, such as aluminum alloy, titanium alloy, stainless steel alloy, etc., and conduct quality inspection.

Drawing design: Use CAD/CAM software to carry out detailed three-dimensional design to ensure that the geometric dimensions, tolerances and surface quality of the parts meet the requirements.

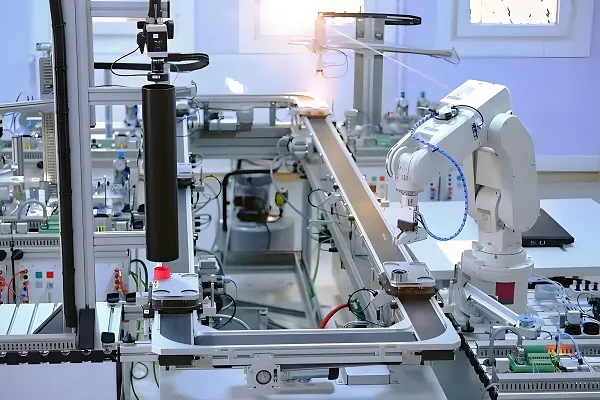

Precision machining: High-precision equipment such as CNC machine tools, laser cutting, EDM, etc. are used to perform machining operations such as cutting, milling and drilling of alloy materials.

Heat treatment: according to the characteristics of the material and use requirements, annealing, quenching, tempering and other heat treatment processes to improve the hardness and wear resistance of the parts.

Surface treatment: carry out surface treatment such as polishing, sandblasting, electroplating, etc. on the parts to improve their surface finish and corrosion resistance.

Quality Inspection: Using CMM, hardness tester and other inspection equipment, the size, shape, surface quality and material properties of the parts are comprehensively inspected.

Packaging and Delivery: The qualified parts are cleaned, rust-proofed and properly packaged to ensure that they are not damaged during transportation.

2.Alloy precision machining parts customization

Demand analysis: Communicate with customers in depth to understand the specific use scenarios, performance requirements and quantity and other needs.

Program design: According to the customer’s needs, design reasonable parts structure, material and processing technology program.

Quotation and Confirmation: Provide detailed quotation, including material cost, processing cost, transportation cost, etc., and confirm the order with the customer.

Sample making: Before formal production, make samples for customers’ confirmation to ensure that the design requirements are met.

Batch production: according to the customer’s demand, batch processing and production, to ensure the quality and delivery time.

After-sales service: provide technical support and after-sales service to ensure that customers get timely help in the process of use.

3.Alloy precision machining parts material introduction

Material: aluminum alloy, titanium alloy, stainless steel alloy

Characteristics:

Aluminum alloy: low density, high strength, good corrosion resistance, easy to process into complex shapes.

Titanium alloy: high strength, low density, high temperature and corrosion resistance, suitable for high temperature and high pressure environment.

Stainless steel alloy: corrosion resistance, high temperature resistance, wear resistance, with good mechanical properties and processing performance.

Characteristics of precision machined parts of alloys of different materials

Products: aluminum alloy precision machined parts, titanium alloy precision machined parts, stainless steel alloy precision machined parts

Data:

Aluminum alloy: density of about 2.7g/cm³, tensile strength up to 400MPa or more, excellent corrosion resistance.

Titanium alloy: density of about 4.5g/cm³, tensile strength up to 800MPa or more, high temperature resistance up to 500 ℃ or more.

Stainless steel alloy: density is about 7.8g/cm³, tensile strength can be up to 1000MPa or more, excellent corrosion resistance, high temperature resistance can be up to 800℃ or more.

Customized Alloy Precision Machined Parts FAQ

Q1: What alloy materials do you provide customized service?

A1: We provide customized service of many alloy materials such as aluminum alloy, titanium alloy, stainless steel alloy, etc. We choose the right material according to customer’s demand.

Q2:How is your machining precision?

A2: We use high-precision machining equipment and technology to ensure that the machining accuracy of parts reaches within ±0.01mm to meet the requirements of precision mechanical systems.

Q3:Do you provide sample making?

A3: Yes, we will make samples for customers to confirm before formal production to ensure that we meet the design requirements before mass production.

Q4:What is your delivery time?

A4:The delivery period depends on the quantity of the order and the difficulty of processing, we will negotiate with the customer to determine the specific delivery time, and ensure on-time delivery.

Q5: Do you provide after-sales service?

A5:Yes, we provide comprehensive after-sales service, including technical support, quality problem handling and maintenance, etc., to ensure that customers get timely help in the process of using.