Product Overview

Check valve injection molded parts serve as core components in fluid control systems, primarily functioning to allow fluid passage in a specific direction while preventing reverse flow. Through precision injection molding processes, thermoplastic materials are transformed into parts with complex geometries and precise dimensions, ensuring efficient and reliable operation of check valves in fluid systems.

Technical Positioning

- Core Function: Unidirectional fluid control, preventing medium backflow

- Application Fields: Petrochemical, pharmaceutical, food and beverage, water treatment, energy, etc.

- Technical Standards: Compliant with ISO 15848-1 Leakage Class V standards

I. Production Process of Check Valve Injection Molded Parts

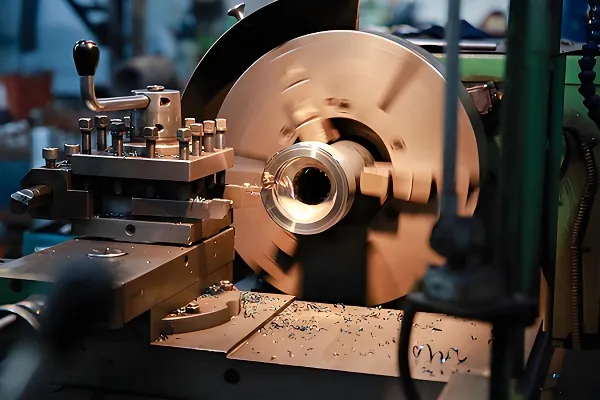

1.1 Mold Design and Manufacturing

Based on check valve design drawings, precisely calculate mold dimensions, structure, and materials to manufacture high-precision, long-life injection molds.

Technical Requirements:

- Surface Roughness: Ra ≤ 0.8μm

- Mold Lifespan: ≥ 500,000 molding cycles

- Compliant with GB/T 12554 Plastic Injection Mold Technical Specifications

1.2 Material Selection and Pretreatment

Select appropriate thermoplastic materials based on check valve working environment and performance requirements, and perform drying, mixing, and other pretreatment processes to ensure stable material performance.

Common Materials:

- Polypropylene (PP): Density approx. 0.9g/cm³, Tensile Strength ≥ 30MPa, Flexural Strength ≥ 40MPa, Heat Distortion Temperature ≥ 80°C

- Nylon (PA): Density approx. 1.15g/cm³, Tensile Strength ≥ 60MPa, Flexural Strength ≥ 90MPa, Heat Distortion Temperature ≥ 150°C

- Polyvinyl Chloride (PVC): Density approx. 1.4g/cm³, Tensile Strength ≥ 40MPa, Flexural Strength ≥ 60MPa, Heat Distortion Temperature ≥ 65°C

1.3 Injection Molding Process

Inject pretreated materials into molds, and through heating and pressure, cure and mold materials within molds to form main components of check valves.

Process Parameters:

- Barrel Temperature: Front section 70~95°C, Rear section 40~60°C

- Mold Temperature: Fixed mold 165~175°C, Moving mold 170~180°C

- Injection Pressure: 80~150MPa

1.4 Post-processing

Perform deburring, trimming, inspection, and other post-processing on injection molded check valve parts to ensure products meet design requirements.

Quality Control:

- Dimensional Accuracy Inspection: 3D Coordinate Measuring Machine

- Surface Quality Inspection: Visual Inspection System

- Performance Testing: Pressure testing, Seal testing

1.5 Assembly and Testing

Assemble check valve injection molded parts with other components into complete check valves, and conduct performance testing to ensure key indicators such as flow rate, pressure loss, and sealing meet required standards.

Testing Standards:

- Sealing: Zero leakage standard

- Opening/Closing Performance: Response time ≤ 0.5s

II. Customization Services for Check Valve Injection Parts

2.1 Personalized Design Services

Provide personalized design services for check valve injection parts based on specific customer needs, including customization of shape, size, material, etc.

Design Capabilities:

- Computational Fluid Dynamics Simulation

2.2 High-precision Processing Technology

Adopt advanced injection molding technology and equipment to ensure processing precision of one-way valve injection molded parts reaches within ±0.05mm, meeting customer precision requirements.

Technical Advantages:

- Multi-axis Injection Molding Machines

- Precision Mold Technology

- Automatic Control Systems

2.3 Mass Production Capacity

Possess large-scale injection molding production lines and efficient production management systems, capable of meeting large customer demands for check valve injection molded parts, ensuring product delivery time and price advantages.

Production Scale:

- Annual Capacity: 1,000,000 pieces

- Production Cycle: 7-15 working days

- Quality Assurance: ISO 9001 certification

2.4 After-sales Service System

Provide comprehensive after-sales services, including technical support, quality assurance, maintenance, and replacement, ensuring customers receive timely and effective support during usage.

Service Commitments:

- 24-hour Technical Support

- Quality Warranty Period: 1 year

- Rapid Response: Problem resolution within 48 hours

III. Material Characteristics of Check Valve Injection Molded Parts

3.1 Material Types

Mainly use thermoplastic materials such as polypropylene (PP), nylon (PA), polyvinyl chloride (PVC).

3.2 Material Characteristics

3.2.1 Corrosion Resistance

These materials possess excellent corrosion resistance, capable of withstanding erosion from various chemical substances, ensuring stable operation of check valves in harsh environments.

Corrosion Resistance Rating:

- PP: Acid-alkali Resistance Grade A

- PA: Solvent Resistance Grade A

- PVC: Chemical Resistance Grade A

3.2.2 High Strength Performance

These materials have high strength and toughness, capable of withstanding certain pressure and impact, ensuring reliability of check valves in fluid systems.

Mechanical Properties:

- Tensile Strength: PP≥30MPa, PA≥60MPa, PVC≥40MPa

- Flexural Strength: PP≥40MPa, PA≥90MPa, PVC≥60MPa

- Impact Strength: ≥ 5kJ/m²

3.2.3 Wear Resistance

Specially treated thermoplastic materials have excellent wear resistance, capable of extending service life of check valves.

Wear Rate:

- Wear Coefficient: ≤ 0.001mm/1000 cycles

- Service Life: ≥ 500,000 opening/closing cycles

3.2.4 Processability

These materials are easy to injection mold, suitable for manufacturing various complex-shaped check valve injection molded parts with low processing costs.

Processing Advantages:

IV. Characteristics of Check Valve Injection Molded Parts with Different Materials

4.1 Polypropylene (PP) Check Valve Injection Molded Parts

Technical Parameters:

- Density: approx. 0.9g/cm³

- Tensile Strength: ≥ 30MPa

- Flexural Strength: ≥ 40MPa

- Heat Distortion Temperature: ≥ 80°C

- Operating Temperature Range: -20°C~+95°C

- Suitable Media: Food, beverages, tap water, pure water, etc.

4.2 Nylon (PA) Check Valve Injection Molded Parts

Technical Parameters:

- Density: approx. 1.15g/cm³

- Tensile Strength: ≥ 60MPa

- Flexural Strength: ≥ 90MPa

- Heat Distortion Temperature: ≥ 150°C

- Operating Temperature Range: -40°C~+120°C

- Characteristics: Excellent wear resistance and self-lubrication

4.3 Polyvinyl Chloride (PVC) Check Valve Injection Molded Parts

Technical Parameters:

- Density: approx. 1.4g/cm³

- Tensile Strength: ≥ 40MPa

- Flexural Strength: ≥ 60MPa

- Heat Distortion Temperature: ≥ 65°C

- Operating Temperature Range: -20°C~+70°C

- Characteristics: Excellent weather resistance and flame retardancy

V. Frequently Asked Questions about Customized Check Valve Injection Parts

Q1: What is the production cycle for one-way valve injection molded parts?

A1: The production cycle mainly depends on product complexity, quantity, and raw material preparation. Generally, it takes 7-15 working days from design confirmation to finished product delivery. For urgent orders, we can provide expedited services, with completion possible in as short as 3-5 working days.

Q2: What material options are available for check valve injection molded parts?

A2: We offer multiple material options, including polypropylene (PP), nylon (PA), polyvinyl chloride (PVC), etc. Customers can choose based on actual usage environment and requirements. For special working conditions, we can also provide high-performance material options such as PVDF and PTFE.

Q3: What is the machining accuracy of check valve injection molded parts?

A3: Our check valve injection molded parts can achieve machining accuracy within ±0.05mm, ensuring product dimensional and shape accuracy. For products requiring high precision, we can enhance accuracy to ±0.02mm through special processes.

Q4: Do you support customization of check valve injection parts?

A4: Yes, we provide comprehensive customization services, including material selection, shape design, processing precision, etc., ensuring products can fully meet customer requirements. We have a professional design team and advanced CAD/CAE software, providing one-stop services from concept design to mass production.

Q5: How is the price of injection molded check valve parts calculated?

A5: Price mainly depends on product size, shape, quantity, and material selection. We will provide detailed quotation plans based on specific customer requirements. Generally, larger quantities result in lower unit prices, and we can offer competitive pricing and flexible payment terms.

VI. Technical Advantages and Quality Assurance

6.1 Technical Advantages

- 26 Years of Industry Experience: Specialized in custom parts manufacturing

- Advanced Equipment: Multi-axis injection molding machines, precision mold equipment

- Professional Team: Engineering team with strong technical R&D capabilities

- Quality Certification: ISO 9001 quality management system certification

6.2 Quality Assurance

- Raw Material Control: High-quality raw materials with strict inspection

- Process Control: Full-process monitoring with real-time adjustments

- Finished Product Inspection: 100% full inspection to ensure quality

- After-sales Guarantee: Quality warranty period with rapid response

6.3 Service Commitments

- Delivery Guarantee: On-time delivery with rapid response

- Technical Support: Professional engineers with technical guidance

- Continuous Improvement: Customer feedback with constant optimization

- Honest Cooperation: Fair transactions with long-term partnerships

VII. Application Cases and Industry Recognition

7.1 Typical Application Cases

Case 1: Petrochemical Industry

A large petrochemical enterprise selected our PP material check valves for acidic medium transportation systems. They operated stably without leakage issues, with service life exceeding expectations by 30%.

Case 2: Pharmaceutical Industry

An internationally renowned pharmaceutical company adopted our PA material check valves, meeting GMP requirements and ensuring safe and reliable fluid control during pharmaceutical production processes.

Case 3: Water Treatment Industry

A municipal sewage treatment plant selected our PVC material check valves, which operated stably for long periods in corrosive environments, reducing maintenance costs by 50%.

7.2 Industry Recognition

- Customer Satisfaction: Over 98%

- Repeat Order Rate: Over 85%

- Industry Certifications: ISO 9001, ISO 14001, OHSAS 18001

VIII. Contact Us

Xiamen Goldcattle Industrial & Trade Co., Ltd.

- Address: Xiamen City, Fujian Province, China

We look forward to cooperating with you to create better quality and more reliable fluid control products!

This technical document is copyrighted by Xiamen Goldcattle Industrial & Trade Co., Ltd. Reproduction or copying without permission is prohibited.