In the field of modern furniture manufacturing, the precision, design complexity, and durability of fittings directly affect the quality of furniture and the user experience. With the increasing demand from consumers for personalized and high – quality furniture, CNC (Computer Numerical Control) technology, with its excellent precision machining capabilities and flexible design adaptability, has become the core technical support for customizing furniture fittings. This article will systematically analyze the technical logic and engineering value of customized CNC furniture fittings from dimensions such as technical advantages, materials engineering, processing technology, quality control, and industry applications.

I. Core Advantages of CNC Technology in Customizing Furniture Fittings

CNC technology provides three core supports for the processing of furniture fittings through digital control and multi – axis linkage capabilities:

Micron – level Precision Assurance

The positioning accuracy of CNC machine tools can reach ±0.01mm, the repeat positioning accuracy is ±0.02mm, and the surface roughness Ra≤0.8μm. For example, when processing the mortise – and – tenon joints of solid – wood furniture, the fit tolerance between the tenon and the mortise can be controlled within ±0.05mm, ensuring the stability and aesthetics of furniture assembly.

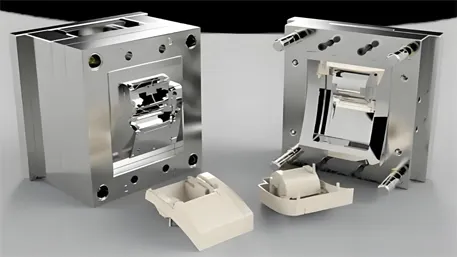

Full – dimensional Machining Ability for Complex Structures

Five – axis CNC equipment can achieve the processing of three – dimensional carvings, special – shaped curved surfaces, and thin – wall structures (wall thickness ≤ 1mm) that are difficult to complete with traditional processes. For example, the wavy table legs and hollow partition screens of customized furniture can be formed in one – step through five – axis milling, avoiding the accumulation of errors from multiple processes.

High Compatibility of Materials and Processes

CNC technology is compatible with a variety of materials such as solid wood (oak, walnut), artificial panels (medium – density fiberboard, plywood), metals (aluminum alloy, stainless steel), and plastics. For different material characteristics, cutting parameters can be optimized: when processing solid wood, high – speed milling (HSC) technology is adopted, with a rotation speed of 10000r/min and a feed rate of 3000mm/min to reduce wood chipping; when processing metal fittings, carbide tools are used to ensure surface finish and dimensional accuracy.

II. Materials Engineering and Selection Strategies for Customizing Furniture Fittings

Material selection is a crucial link in customizing furniture fittings and needs to be combined with furniture functions, design styles, and cost requirements:

Balance of Functionality and Aesthetics

Solid wood materials: Natural woods such as oak and walnut can achieve complex patterns through CNC carving, combining texture and aesthetic value, which are suitable for high – end customized furniture.

Artificial panels: Medium – density fiberboard and plywood are low – cost and easy to process. They can be made into flat cabinet side panels and drawer fronts through CNC milling, and the surface can be veneered or painted.

Durability and Environmental – friendliness Design

Metal fittings: Aluminum alloy (6061) or stainless steel (304) are used for furniture hardware (such as hinges, handles), with a tensile strength of ≥290MPa and passing the 48 – hour salt – spray test for corrosion resistance to ensure long – term use.

Environment – friendly materials: Bamboo fiber boards, recycled plastics, and other eco – friendly materials are processed into furniture fittings through CNC, in line with the green concept of modern homes.

Optimization of Cost and Process

Economical solution: Medium – density fiberboard or pine wood is made into basic furniture frames through CNC milling, with a cost 50% lower than that of solid wood, which is suitable for mass customization.

High – end application: Precious woods such as mahogany and teak are precisely carved by CNC to achieve detailed designs that are difficult to complete with traditional processes, enhancing the artistic value of furniture.

III. Analysis and Innovation of CNC Processing Technology

In response to the diverse needs of furniture fittings, CNC processing technology achieves a double breakthrough in efficiency and quality through the following techniques:

Multi – axis Linkage Composite Machining

Five – axis linkage milling can complete three – dimensional carvings and curved – surface modeling. For example, the cylindrical table legs and wavy chair backs of furniture can complete the processing of complex contours in one clamping, with a 60% increase in efficiency.

Four – axis processing can achieve multi – angle grooving and drilling of panels. For example, the connection hole positions of customized cabinets have a position accuracy of ±0.02mm.

High – speed Cutting and Precision Carving

When processing solid wood, high – speed milling (HSC) technology can reduce wood thermal deformation and ensure clear carving details. For example, the depth error of CNC – carved rose patterns is ≤0.1mm.

In the processing of metal fittings, the combination of CNC turning and milling can achieve high – precision threads and chamfers. For example, the surface roughness of aluminum alloy handles is Ra≤0.4μm.

Enhancement of Surface Treatment Processes

After CNC milling, solid – wood fittings can be sanded, painted, or treated with wood wax oil to improve texture and weather resistance.

Metal fittings are treated by anodizing, electroplating, or polishing to enhance wear resistance and aesthetics. For example, the mirror polishing of stainless – steel handles has a Ra value of ≤0.2μm.

IV. Quality Control System for Customizing Furniture Fittings

To ensure that products meet furniture industry standards and user requirements, customized CNC furniture fittings need to go through a strict quality control process:

Dimension and Geometric Tolerance Detection

A coordinate measuring machine (CMM) is used to detect key dimensions. For example, the tolerance of hinge hole positions on cabinet doors is ≤±0.02mm.

Geometric tolerance detection: The flatness is ≤0.1mm/m, and the perpendicularity is ≤0.05mm to ensure the assembly accuracy of fittings.

Materials and Performance Verification

The moisture content of solid – wood fittings is tested (8% – 12%) to avoid deformation; the formaldehyde emission of artificial panels is tested (E0 level ≤ 0.05mg/m³).

Tensile tests (such as the tensile strength of 6061 aluminum alloy ≥ 290MPa) and hardness tests are carried out on metal fittings to ensure their mechanical properties.

Surface Quality and Function Detection

The Ra value of the surface is detected by a roughness tester. Solid – wood fittings need to reach Ra≤1.6μm, and metal fittings need to reach Ra≤0.8μm.

Functional tests: For example, the sliding life test of drawer guides (50,000 open – and – close cycles without failure) is carried out to ensure reliable use.

V. Industry Application Practices

Customized Cabinets and Wardrobes

The side panels of medium – density fiberboard cabinets are milled and formed by CNC, with a dimensional tolerance of ±0.02mm. After surface veneering, they are flat and beautiful, and are suitable for various hardware connections.

Aluminum alloy cabinet handles are turned and anodized by CNC, with a surface hardness of HV120 or above, and the scratch – resistance is increased by 3 times.

High – end Solid – wood Furniture

The table legs of walnut wood are carved by five – axis CNC to achieve complex curve shapes, with a surface roughness of Ra≤0.8μm. Matched with mortise – and – tenon joints, they have excellent stability.

Mahogany screens are hollow – carved by CNC, with a pattern accuracy of ±0.1mm, inheriting traditional craftsmanship while improving production efficiency.

Modern and Simple Furniture

The stainless – steel coffee – table frame is bent and polished by CNC, with a surface Ra value of ≤0.4μm. The right – angled corners have a natural arc transition, combining industrial texture and safety.

Plastic furniture feet are injection – molded and precisely processed by CNC, with a dimensional tolerance of ±0.05mm. Their wear resistance can pass the 5000 – hour abrasion test, which is suitable for office furniture.

VI. Frequently Asked Questions (FAQ)

What level of precision can customized CNC furniture fittings achieve?

CNC processing can achieve a dimensional tolerance of ±0.01mm, a repeat positioning accuracy of ±0.02mm, and a surface roughness Ra≤0.8μm, meeting the precise assembly requirements of high – end furniture.

How to choose suitable materials?

It is necessary to choose according to the furniture style and function. Solid wood is suitable for high – end customization, artificial panels are economical and practical, metal fittings improve durability, and plastic fittings are lightweight and flexible.

How long is the production cycle for customizing furniture fittings?

The production cycle depends on the complexity of the fittings and the materials. Simple parts usually take 3 – 7 days, and complex carved parts may take 10 – 15 days. Urgent customization is supported to shorten the delivery time.

Can CNC processing achieve personalized design?

Yes, CNC technology can accurately realize various complex shapes according to CAD drawings, such as carvings and special – shaped structures, to meet the personalized needs of users.

What about the cost of customizing furniture fittings?

The cost is affected by materials, processing complexity, and quantity. The cost of small – batch customization is relatively high, but CNC technology reduces the unit cost by optimizing processes. In the long run, the cost – performance ratio is better than that of traditional processes.

Consult Now and Get a Tailored Solution!

Whether it is the carved fittings of high – end solid – wood furniture, the precision hardware of modern cabinets, or the personalized creative furniture design, our professional team will rely on the high precision and flexibility of CNC technology, combined with materials engineering and process innovation, to provide you with a full – process customization service from design, processing to inspection. Click to leave a message, and let us use a rigorous technical system and innovative design concept to customize high – performance and high – appearance – value CNC fittings for your furniture projects, helping you create a unique and high – quality home space!