With the increasing popularity of smartphones, cell phone cases are not only a necessity to protect your phone, but also a fashion accessory to show your personality and taste. In order to meet the market’s urgent demand for high-quality, personalized phone cases, Xiamen Goldcattle provides one-stop customized phone case mold service, with exquisite craftsmanship, rigorous process, to create a unique phone case mold solutions for each customer.

1.Demand Analysis: Precise positioning, customization

Segment Overview: The service begins with a deep understanding of the customer’s needs. Our professional team will communicate one-on-one with customers to understand in detail their specific requirements in terms of phone case material, color, pattern, function, etc., as well as the preferences and needs of target user groups. Through meticulous demand analysis, we ensure that each mold can accurately meet the customer’s individual needs.

Core highlights: personalized customization to meet the needs of different scenarios and styles; accurately grasp the market trends and lead the trend.

2.Design development: unlimited creativity, accurate presentation

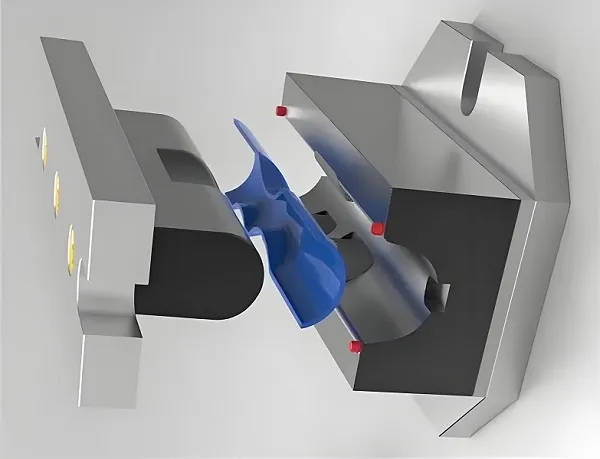

Segment Overview: Based on the results of the demand analysis, our design team will use advanced CAD/CAM software to carry out three-dimensional modeling and creative design of cell phone cases. During the design process, we pay attention to details to ensure that the pattern lines are smooth and the colors are harmonious, while taking into account the practicality and aesthetics of the phone case. Upon completion of the design, we will generate detailed design drawings and 3D renderings for customers to review and confirm.

Core highlights: innovative design concepts, leading the industry trend; accurate modeling technology to ensure that the design effect is perfectly presented.

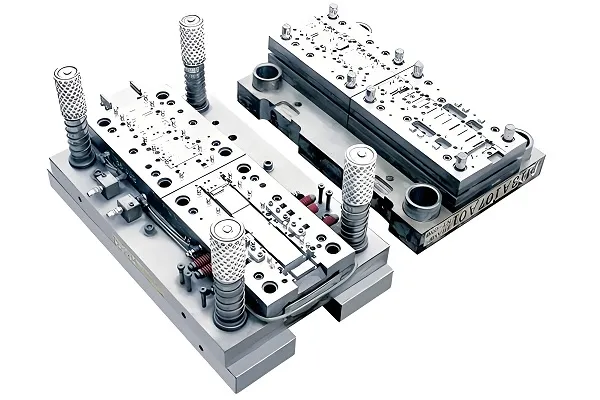

3. Mold Manufacturing: Precision work, quality assurance

Overview: Mold manufacturing is the core link of customized phone cases. We use high-precision CNC machining centers, EDM and other advanced equipment to accurately process the mold cavities and structural parts according to the design drawings. During the manufacturing process, we strictly control the processing precision and material quality to ensure the durability and stability of the mold. At the same time, we pay attention to the cooling system and exhaust design of the mold to improve the injection molding efficiency and product quality.

Core highlights: advanced processing equipment to ensure mold precision and quality; scientific design principles to enhance the injection molding effect.

4. Injection molding production: high efficiency and stability, consistent quality

Segment Overview: After the mold manufacturing is completed, we will enter the injection production stage. We choose high quality injection materials, and after preheating, injection, cooling, demolding and other processes, the molten plastic is injected into the mold cavity to form the phone case. We strictly control the parameters of the injection molding process, such as temperature, pressure, time, etc., to ensure that each piece of phone case can achieve the expected dimensional accuracy, appearance quality and physical properties.

Core highlights: High-efficiency injection molding production line to ensure production speed and output; strict quality control system to ensure stable product quality.

5. Post-processing and inspection: Keep improving, pursue excellence.

Segment Overview: After the injection molding production is completed, we will also carry out a series of post-processing and testing work for the chassis. Including the removal of flying edges, grinding and polishing, surface spraying or plating and other treatment processes, in order to enhance the appearance of the phone case texture and protective properties. At the same time, we use advanced testing equipment and methods to comprehensively test the size, appearance, and performance of phone cases to ensure that each product meets customer satisfaction standards.

Core highlights: meticulous post-treatment process to enhance the added value of products; strict quality inspection process to ensure zero defects.

6. Delivery and after-sales service: attentive service, worry-free throughout the whole process

Segment Overview: After completing all the production links, we will deliver the customized phone case molds and samples to customers according to the agreed time, place and way. At the same time, we provide a perfect after-sales service system, including mold maintenance and maintenance guidance, injection molding production technical support, etc., to ensure that any problems encountered by the customer in the process of use can be resolved in a timely and effective manner.

Core highlights: efficient and convenient delivery process, so that customers save effort; attentive and thoughtful after-sales service, so that customers have no worries.

Xiamen Goldcattle has won wide recognition and praise in the field of customized cell phone case mold service by virtue of its professional technical strength, rigorous service process and excellent product quality. We are committed to providing customized mold solutions for each customer, so that each phone case can become a unique work of art. Choosing us is choosing quality and trust!

Xiamen Goldcattle Customized Phone Case Mould Service FAQ

1. What is the process of customized phone case mold?

A: The process of customized cell phone case mold usually includes demand analysis, design and development, mold manufacturing, injection production, post-processing and testing, as well as delivery and after-sales service. First of all, we will communicate with customers to clarify their individual needs; then, the design team will carry out 3D modeling and creative design, and generate detailed design drawings; then, the mold manufacturing team will process the molds according to the design drawings; after the molds are completed, we will carry out the injection molding production, and carry out the post-processing and testing of the products; finally, we will deliver the qualified products to the customers, and provide perfect after-sales service.

2. How long does it take to make customized phone case mold?

A: The time for customized phone case mold varies depending on the complexity of the project and the customer’s demand. Generally speaking, it takes several weeks to several months from the demand analysis to the completion of mold manufacturing. The exact time will also be affected by the difficulty of mold design, material procurement, processing equipment scheduling and other factors. We will fully communicate with our customers to make a reasonable project schedule and try our best to ensure on-time delivery.

3. What are the choices of material for customized phone case mold?

A: There are various choices of materials for custom phone case molds, commonly including aluminum alloy, steel, stainless steel and other metal materials. These materials have good mechanical properties, processing performance and wear resistance, which can meet the needs of different customers. When choosing the material, we will consider the service life of the mold, the production cost and the customer’s specific requirements for the product.

4. How to ensure the precision and quality of the customized phone case molds?

A: We use advanced equipment and technology such as high-precision CNC machining centers and EDM to ensure the machining precision and surface quality of the molds. During the manufacturing process, we strictly control every production link and conduct comprehensive inspection on the size, shape and structure of the molds. Meanwhile, we have experienced technicians and strict quality management system to ensure that the quality of the molds meets customer requirements and industry standards.