Dude, we’re talking about the ULTIMATE protection for your precious communication gear! Whether it’s 5G routers, outdoor antennas, or sensitive transceivers, we’ve got the perfect plastic shell to keep them safe from the elements.

Hey, I’m Li Gong – Your Plastic Housing Guru!

Bro, I’ve been messing with communication plastic enclosures for 15 YEARS! Seen it all, done it all. From designing super-tough 5G base station housings to solving weird EMI shielding problems – I’m your guy.

📞 5G Project Experience: 100+ successful projects

🛡️ Certifications: ISO 9001, IP67, RoHS, UL94

📅 Last Updated: January 26, 2026

Industrial-grade communication equipment housing

Why Custom Enclosures? Because Standard Sucks!

Perfect Fit Every Time

Bro, standard enclosures are like one-size-fits-all shoes – they never fit right! Custom enclosures? EXACT match for your device’s dimensions, ports, and mounting points. No more forcing things or ugly gaps!

Environmental Superpowers

Need waterproofing for outdoor antennas? EMI shielding for sensitive gear? Heat dissipation for high-power devices? We got you! Generic enclosures can’t handle the real-world abuse your equipment faces.

Branding & Usability

Add your logo, custom colors, or ergonomic grips – make your equipment stand out! And let’s be real, better design = happier users. Win-win!

Custom ABS plastic enclosure – look at that perfect finish!

Materials That Actually Perform (No Cheap Junk Here!)

ABS (Acrylonitrile Butadiene Styrene)

The OG workhorse! Perfect balance of strength, impact resistance, and cost. Dude, I’ve used this stuff for years – it’s like the Swiss Army knife of plastics. Great for indoor gear like routers and modems.

Impact Strength: 16 kJ/m² (that’s tough!)

Heat Resistance: Up to 80°C

Best For: Indoor communication devices

PC (Polycarbonate)

THE ULTIMATE SHIELD! 20x stronger than glass, bro. This stuff can take a beating – perfect for outdoor antennas and devices that need to survive the elements. And it’s transparent too!

Impact Strength: 65 kJ/m² (insane!)

Heat Resistance: Up to 130°C

Best For: Outdoor equipment, high-impact areas

PC/ABS Blend

The dream team! Combines PC’s impact resistance with ABS’s flexibility and cost. Dude, this is my go-to for most projects – it’s like getting the best of both worlds without compromise.

Impact Strength: 45 kJ/m²

Heat Resistance: Up to 110°C

Best For: Most communication equipment

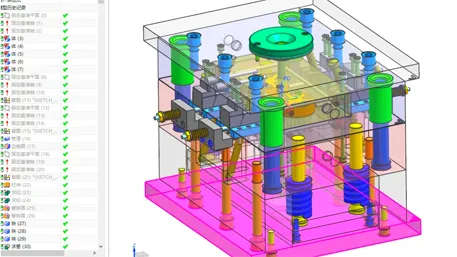

Processing Tech That Actually Works (No Sketchy Methods!)

Injection Molding

THE BIG DOG! For high-volume production. Melts plastic and injects it into precision molds. Dude, we’re talking ±0.05mm tolerance – that’s like surgical precision! Perfect for complex designs with tight specs.

CNC Machining

PROTOTYPING HERO! Carves solid plastic blocks with computer-controlled routers. Great for small batches or when you need to tweak designs fast. No waiting for molds!

3D Printing

RAPID PROTOTYPING GOD! Builds layer-by-layer. Perfect for testing unique designs or super-custom parts. Dude, we can have a prototype in your hands in DAYS, not weeks!

CNC machined communication equipment housing – precision at its best!

Testing That Actually Matters (No Fake Certifications!)

Real-World Test Data (2025 Client Project)

*Data from actual 5G base station housing project – results may vary based on specific design*

Impact Resistance: >50J (survived 2m drop test with NO damage!)

IP Rating: IP67 (completely dust-tight, survives 1m water immersion for 30 mins)

EMI Shielding: 65 dB (blocks 99.999% of electromagnetic interference)

Temperature Range: -40°C to +85°C (works in Antarctica AND desert!)

Flame Rating: UL94 V-0 (self-extinguishing within 10 seconds)

Standards We Actually Follow (Not Just Stickers!)

Bro, certifications aren’t just marketing fluff – they mean something! We test EVERYTHING to meet these standards:

ISO 9001: Quality management system

IEC 60529: IP rating standards (dust/water protection)

UL 50: Electrical enclosure safety

UL 94: Flammability testing

RoHS: Restriction of hazardous substances

NEMA 4X: Extreme environmental protection

2026 Trends – Stay Ahead of the Game!

Sustainable Materials

The future is green! Biodegradable plastics like PHA are gaining traction. By 2030, 20% of enclosures will use sustainable materials. Dude, it’s not just eco-friendly – it’s good business too!

AI & Automation

Smarter manufacturing! AI-powered defect detection is increasing quality rates by 20%. Automated production lines mean faster turnaround and better consistency. Technology for the win!

5G/6G Expansion

More speed, more demand! 5G/6G equipment needs specialized enclosures. Demand is growing at 45% annually. Get in now before the rush!

Xiamen Goldcattle – Your Custom Enclosure Partner

One-Stop Solution

From design to delivery, we handle everything. Dude, no need to coordinate with multiple suppliers – we’ve got the whole process covered under one roof!

- Design & engineering support

- Material selection guidance

- Mold fabrication

- Production & finishing

- Quality testing & certification

Advanced Capabilities

We’re not your average factory, bro. We’ve got the latest equipment and experienced engineers to handle even the most complex projects.

- Precision injection molding (±0.05mm tolerance)

- CNC machining for prototyping

- 3D printing for rapid prototyping

- Ultrasonic welding for hermetic seals

- EMI/RFI shielding technologies

Ready to Get Started?

Whether you need a prototype or mass production, we’re here to help! Share your specs and let’s create something awesome together.

FAQ – Questions We Actually Get Asked (No Boring Stuff!)

Which material is best for outdoor enclosures?

Bro, PC or PC/ABS blend all the way! PC is 20x stronger than glass and handles temperature extremes like a champ. We’ve tested this stuff in -40°C to +85°C – it doesn’t break a sweat!

How long does custom enclosure production take?

Prototyping: 1-2 weeks (3D printing/CNC)

Production tooling: 4-6 weeks

Mass production: 2-3 weeks after tooling

Dude, we can rush if you need it – just ask!

Can you do custom port configurations?

Absolutely! We can make any port configuration you need – Ethernet, USB, coaxial, whatever. Our 3D modeling ensures perfect alignment every time. No more guessing!

Do you test for environmental resistance?

Of course we do! We test everything – IP rating verification, temperature cycling, vibration testing, you name it. We don’t just say it’s tough – we prove it!

Xiamen Goldcattle Plastic & Metal Products Co., Ltd.

Custom Plastic Housing Experts Since 2010 | ISO 9001 Certified | 100+ 5G Projects Completed