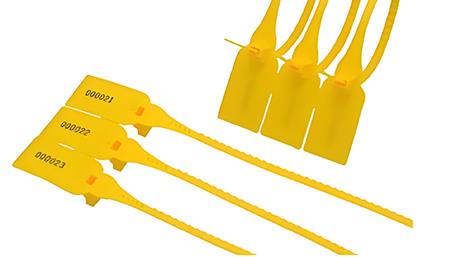

Plastic airtight seal is a kind of fixing tool based on plastic material, which is widely used in logistics, transportation, aviation, household, outdoor and other fields. It meets the sealing and fixing needs of different industries with its convenient use and safety.

1.Plastic sealing production process

Raw material preparation: Choose high quality plastic raw materials, such as polypropylene (PP), polyethylene (PE) or nylon (PA), to ensure the strength and durability of the product.

Mold design: Make precise molds according to customer’s needs and product design requirements.

Injection Molding: The plastic raw material is heated and melted, then injected into the mold and cooled to form the initial shape of the dense blockade.

Post-processing: Trimming and polishing the injection molded sealing blockade to ensure that the appearance and size of the product meet the requirements.

Quality Inspection: Strict quality inspection of the finished product, including strength test, durability test, etc., to ensure that the product meets the relevant standards and customer needs.

2.Plastic sealing customization

Demand analysis: Communicate with customers to understand their specific needs and application scenarios, such as size, color, shape and so on.

Design: According to the customer’s needs, design the sealing program to meet the requirements, and provide detailed drawings and samples.

Mold making: Make the mold according to the design scheme to ensure the accuracy and consistency of the product.

Mass production: After the mold is made, mass production will be carried out to ensure the quality and delivery time of the products.

After-sales service: Provide perfect after-sales service, including product use guidance, maintenance and replacement.

3.Plastic sealing material

Material: polypropylene (PP), polyethylene (PE), nylon (PA) and so on.

Characteristics:

Corrosion resistance: Plastic seal has excellent corrosion resistance and can be used for a long time in harsh environments such as humidity, acid and alkali.

Light weight: Compared with metal seals, plastic seals have a lighter weight, easy to carry and install.

Easy to process: Plastic seals are easy to process and mold, and can be customized in various shapes and sizes according to customers’ needs.

Low cost: Plastic raw material prices are relatively low, making the plastic seal has a lower cost, more competitive market.

4. Characteristics of plastic sealing blockade made of different materials

Products: Polypropylene (PP) sealing, polyethylene (PE) sealing, nylon (PA) sealing.

Data:

Polypropylene (PP) sealing:

Strength: ≥20MPa

Density: 0.9g/cm³

Temperature resistance range: -30℃~+120

Abrasion resistance: good

Polyethylene (PE) airtight seal:

Strength: ≥15MPa

Density: 0.92g/cm³

Temperature resistance range: -40℃~+80

Toughness: excellent

Nylon (PA) sealing blockade:

Strength: ≥50MPa

Density: 1.1g/cm³

Temperature resistant range: -20℃~+100℃

Corrosion resistance: excellent

5.Plastic sealing application

Logistics industry: used for sealing and encapsulating express bags, pouches, express boxes and other products, preventing parcels from being opened illegally during transportation.

Transportation industry: Used for binding and fixing of containers, wooden crates, tin boxes and other goods, to ensure the safety of goods in the transportation process.

Aviation industry: Used for sealing and fixing luggage and aviation containers to ensure the safety of luggage and goods.

Home and Outdoor: Used for the safe locking of shoe cabinets, file cabinets, lockers and other household items, as well as the fixing of backpacks, tents and other items in outdoor activities such as camping and hiking.

Customized Plastic Sealer FAQ

Q1: What are the advantages of plastic seal?

A1: Plastic seal has the advantages of light weight, corrosion resistance, easy processing, low cost and so on.

Q2: What is the customization process of plastic seal?

A2: The customization process includes demand analysis, design, mold making, mass production and after-sales service.

Q3:What are the differences between different materials of plastic sealing blockade?

A3: There are differences in strength, density, temperature resistance and abrasion resistance between different materials, so customers can choose the right material according to their specific needs.

Q4: What is the service life of plastic seals?

A4:The service life of plastic seals depends on the material, the environment and the way of use, etc. Generally speaking, the service life of high quality plastic seals depends on the material, the environment and the way of use. Generally speaking, high-quality plastic seal has a long service life.

Through the above introduction, I believe you have a deeper understanding of customized plastic sealing blockade. If you have any questions or needs, please feel free to contact us.