Tail light plastic plate is an important part of the rear part of the car, not only has the function of beautiful body, but also can effectively protect the tail light from external collision and scratches, to extend the service life of the tail light. There are many kinds of tail light plastic plates, and the names and styles vary according to the different models and brands. Common tail lamp plastic plate includes tail lamp decorative cover, tail lamp decorative plate and tail lamp guard plate.

1.Tail lamp plastic plate production process

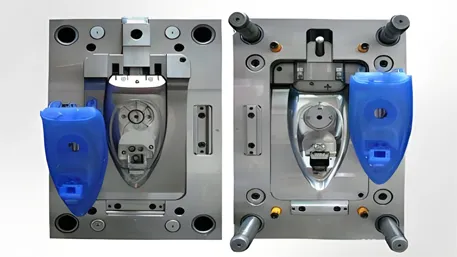

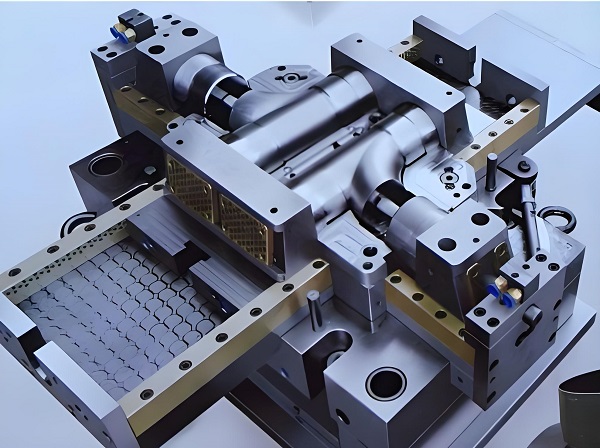

Mould design and manufacture: According to the customer’s demand and the characteristics of the car model, design the mold of the tail lamp plastic plate. The mold design should ensure the precision and appearance quality of the product.

Material preparation: Choose suitable plastic materials, such as polycarbonate (PC), polypropylene (PP), polyamide (PA) or polybutylene sulfide (PBT). These materials have the advantages of light weight, weather resistance, chemical resistance and high temperature resistance.

Injection Molding: The prepared plastic material is heated to a molten state and then injected into the mold for molding. During the molding process, parameters such as temperature, pressure and time need to be controlled to ensure product quality.

Post-processing: After molding, the tail light plastic plate needs to be demolded, trimmed, polished and other post-processing procedures to improve the appearance quality and dimensional accuracy of the product.

Quality Inspection: The quality inspection of the tail light plastic plate includes appearance inspection, size measurement, performance test, etc. to ensure that the product meets the customer’s requirements.

2.Customized tail light plastic plate

Customer demand analysis: Communicate with customers to understand the specific needs of models, colors, sizes, etc., as well as the use of the product environment and special requirements.

Design scheme development: according to the customer’s needs, develop the design scheme of the tail light plastic plate, including shape, structure, material selection and so on.

Quotation and confirmation: According to the design scheme, calculate the product cost and provide quotation to the customer. After the customer confirms the quotation, both parties sign a customized contract.

Production & Delivery: Produce the tail light plastic plate according to the design scheme and production process. Keep communicating with customers during the production process to ensure product quality and delivery time. After the product is completed, quality inspection and packaging, and then delivered to the customer.

3.Tail light plastic plate material

Material: polycarbonate (PC), polypropylene (PP), polyamide (PA), polybutylene sulfide (PBT) and so on.

Characteristics:

Lightweight: These plastic materials have a low density, making the tail light plastic plate lightweight and easy to install.

Weather resistance: able to resist UV rays, high temperature, low temperature and other harsh environments, to maintain stable product performance.

Chemical resistance: strong resistance to acids, alkalis and other chemicals, extending product life.

High temperature resistance: able to maintain stable performance in a certain high temperature environment, no deformation, no melting.

4. Characteristics of tail light plastic sheet of different materials

Products:

Polycarbonate (PC) tail light plastic plate

Data: transmittance up to 80-90%, high temperature stability performance, hardness, strength, toughness.

Polypropylene (PP) tail light plastic plate

Data: good chemical corrosion resistance, lower cost, good processing performance.

Polyamide (PA) tail lamp plastic sheet

Data: high strength, good high-temperature stability, good abrasion resistance, chemical corrosion resistance.

Polybutylene sulfide (PBT) tail lamp plastic sheet

Data: High-performance thermoplastic, excellent electrical and insulating properties, good temperature resistance and corrosion resistance.

Customized Tail Light Plastic Sheet FAQ

Q1: What colors and shapes can be customized for tail lamp plastic sheet?

A1: Tail lamp plastic sheet can be customized in various colors and shapes according to customers’ needs to meet different car models and aesthetic demands.

Q2:What is the delivery time for tail lamp plastic sheet?

A2: The delivery time depends on factors such as production volume, mold manufacturing time and customer demand. Generally speaking, we will negotiate with customers to determine the delivery time and try our best to finish the production on time.

Q3: How do you guarantee the quality of the tail light plastic sheet?

A3: We ensure that the quality of the tail lamp plastic sheet meets customers’ requirements through strict quality inspection and control processes. Meanwhile, we use high-quality plastic materials and advanced production processes to improve the reliability and durability of our products.

Q4: How is the price of tail light plastic sheet calculated?

A4: The price of tail light plastic plate is calculated based on material, size, quantity and other factors. We will provide a detailed quotation according to customers’ requirements and sign a customized contract after both parties confirm.

Q5: What do I need to pay attention to during the installation of tail light plastic plate?

A5:When installing the tail light plastic plate, you need to pay attention to the installation position, fixing method and the cooperation with other parts. Meanwhile, scratches and collisions should be avoided during installation to ensure the appearance quality and performance of the product.