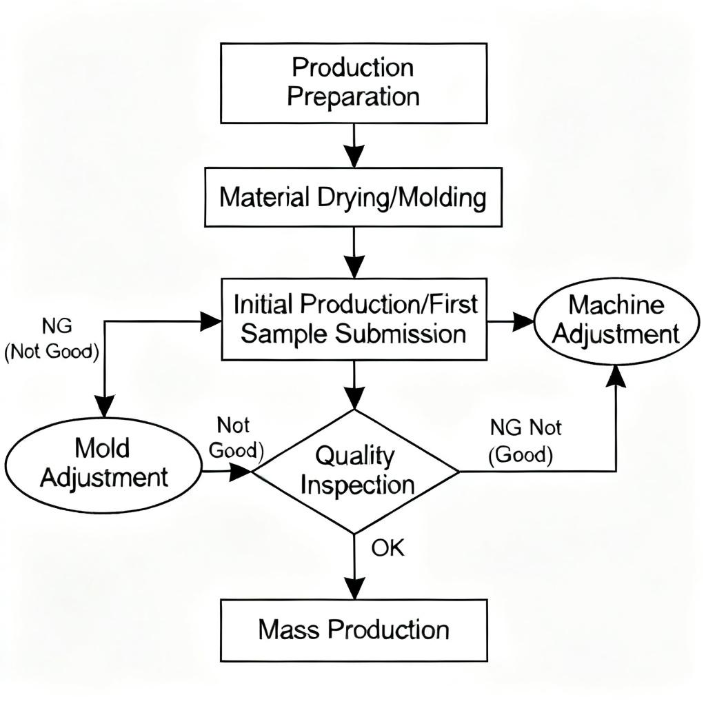

Injection molding is one of the most important plastic processing methods in modern manufacturing. By precisely controlling parameters such as temperature, pressure, and time, it transforms plastic raw materials into products of various shapes. From everyday plastic containers to precision automotive components, injection molding plays an irreplaceable role.

Process Overview

The core of the injection molding process involves heating and melting solid plastic materials, injecting them into mold cavities under high pressure, and obtaining products of the desired shape after cooling and solidification. This process is somewhat like making models with clay, but using more advanced equipment and more precise control technology.

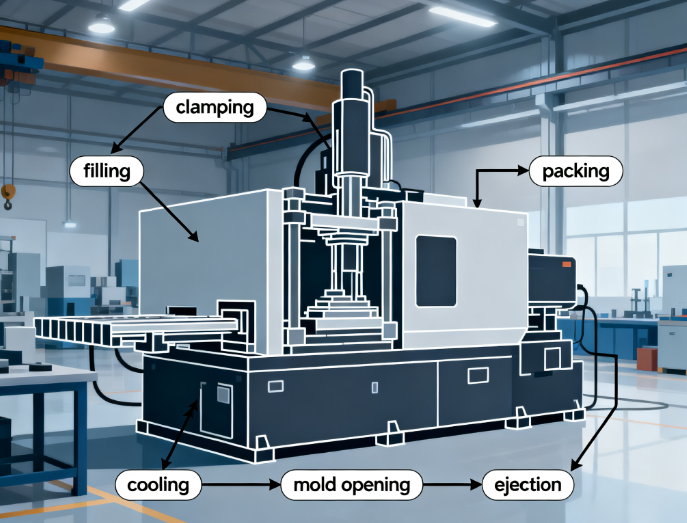

A complete injection molding cycle typically includes six main stages: clamping, filling, packing, cooling, mold opening, and ejection. These six stages are closely interconnected, and the control precision of each stage directly affects the quality of the final product.

Detailed Process Flow

Stage 1: Clamping

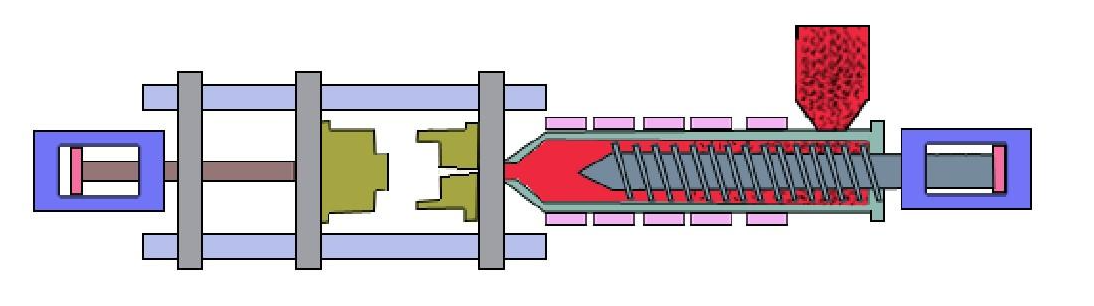

Clamping is the first and fundamental step in injection molding. During this stage, the clamping system of the injection molding machine tightly closes the moving and fixed halves of the mold.

The clamping process needs to provide sufficient clamping force to prevent the mold from opening during the subsequent high-pressure injection process. The magnitude of clamping force depends on the mold size, injection pressure, and product projection area. Generally, larger molds require greater clamping force.

Modern injection molding machines typically use hydraulic or electric drives for their clamping systems, providing precise control of clamping speed and pressure. During the clamping process, the system automatically detects whether the mold is completely closed and ensures safety devices are functioning properly.

Stage 2: Filling

The filling stage involves injecting molten plastic into the mold cavity and is one of the key stages determining product quality.

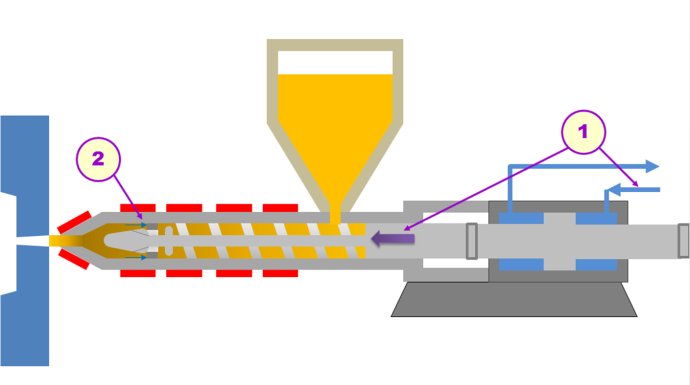

Before filling begins, plastic materials have already been heated and melted in the injection molding machine’s barrel. The screw inside the barrel pushes plastic pellets forward while rotating, and through heating and shearing actions, the plastic is uniformly melted.

When the plastic melt reaches the set temperature and viscosity, the screw starts moving forward, injecting the molten plastic into the mold cavity through the nozzle at high pressure and speed. Injection pressure typically ranges from tens to hundreds of megapascals, and injection speed can reach several tens of centimeters per second.

Key control parameters during the filling process include:

- Injection pressure: Affects melt flow speed and filling effectiveness

- Injection speed: Influences melt flow state and product surface quality

- Injection temperature: Impacts melt viscosity and flowability

- Filling time: Time from start of injection to completion of cavity filling

The length of filling time directly affects production efficiency; theoretically, shorter filling times are better. However, in actual production, filling time needs to be optimized based on material properties, product shape, and mold design.

**

Stage 3: Packing

The packing stage follows immediately after the filling stage and is an important phase ensuring product quality. After the filling stage is completed, the mold cavity is basically filled with plastic, but due to plastic shrinkage during cooling, continued pressure application is needed to supplement the melt.

During the packing stage, the injection molding machine continues to apply pressure to the mold cavity, allowing more molten plastic to enter the cavity to compensate for volume reduction caused by plastic cooling shrinkage. Packing pressure is typically around 80% of the filling pressure.

Pressure transmission during the packing process is very important. Since the mold temperature is relatively low, the plastic near the mold walls begins to cool and solidify first, forming a solidified layer. The packing pressure needs to be transmitted through this solidified layer to the interior of the cavity, pushing more melt to compensate for shrinkage.

The duration of the packing stage depends on the cooling time of the gate. When the gate is completely solidified, packing loses its meaning because the melt can no longer enter the cavity at this point.

The impact of the packing stage on product quality is mainly reflected in:

- Reducing product shrinkage and warpage

- Improving product density and strength

- Enhancing product dimensional stability

- Reducing defects such as bubbles and sink marks

Stage 4: Cooling

The cooling stage is the longest stage in the injection molding cycle, typically accounting for 70% to 80% of the entire cycle. During this stage, the plastic melt inside the mold gradually cools down through the cooling system and eventually solidifies into shape.

Control of the cooling process has an important impact on both product quality and production efficiency. If cooling speed is too fast, it may cause internal stress in the product, leading to warpage and deformation; if cooling speed is too slow, it will extend the production cycle and reduce efficiency.

The design of the mold’s cooling system is crucial. Water circulation is usually used for cooling, and the position, diameter, and distribution of cooling channels all affect cooling effectiveness. In modern mold design, cooling systems are typically optimized according to product shape to achieve uniform cooling.

Main factors affecting cooling time include:

- Product thickness: Thicker products require longer cooling times

- Plastic thermal conductivity: Higher thermal conductivity means faster cooling

- Mold temperature: Lower mold temperature results in faster cooling

- Cooling medium temperature: Lower cooling water temperature provides better cooling effect

Generally speaking, cooling time is proportional to the square of the maximum wall thickness of the product. For example, a product with a wall thickness of 2mm may require approximately 4 seconds of cooling time, while a product with a wall thickness of 4mm would need about 16 seconds.

Stage 5: Mold Opening

After the plastic has sufficiently cooled and solidified inside the mold, the mold opening stage begins. During this stage, the clamping system of the injection molding machine opens the mold in preparation for product removal.

The mold opening process requires control of opening speed and position to ensure operational safety and product quality. Mold opening speed is typically controlled in segments: starting slowly, then gradually accelerating, and finally slowing down again to avoid excessive pulling force on the product during opening, which could cause damage.

During the mold opening process, the system detects the position and status of the mold to ensure it can open smoothly. At the same time, various safety devices start working to prevent accidents during mold opening.

Stage 6: Ejection

Ejection is the final stage of the injection molding cycle and the last quality control phase for the product. During this stage, the molded product is pushed out of the mold through the ejection mechanism of the mold.

Several factors need to be considered during the ejection process:

- Ejection force: Sufficient force is needed to push the product out of the mold, but not so much that it damages the product

- Ejection speed: Affects production efficiency and product quality

- Ejection position: Ejection points should be set at areas of higher product strength to avoid product deformation

- Ejection method: Appropriate ejection method selected based on product shape and structure

Common ejection methods include:

- Ejector pin ejection: Using ejector pins to push out the product, suitable for most products

- Ejector plate ejection: Using an ejector plate to push out the entire product, suitable for deep cavity products

- Stripper plate ejection: Using a stripper plate to separate the product from the mold, suitable for thin-walled products

- Pneumatic ejection: Using compressed air to blow out the product, suitable for small products

After ejection, the product still needs some post-processing, such as removing gates, trimming flash, and surface treatment, to become the final product.

Process Parameter Control

The success of the injection molding process largely depends on the precise control of various process parameters. Here are some key process parameters:

Temperature Control

Temperature control is one of the most basic and important control parameters in injection molding. It mainly includes:

Barrel temperature: Controls the melting state and flowability of the plastic. Different plastic materials require different barrel temperatures, typically between 150°C and 300°C.

Mold temperature: Affects the cooling rate and crystallization state of the plastic. Mold temperature is usually controlled between 40°C and 120°C, depending on the plastic type and product requirements.

Nozzle temperature: Ensures the plastic maintains appropriate flowability during injection, usually slightly lower than the barrel temperature.

Pressure Control

Pressure control directly affects product quality and performance:

Injection pressure: Pressure that pushes the plastic melt to fill the mold cavity, typically between 40MPa and 200MPa.

Packing pressure: Pressure maintained after filling is completed to compensate for plastic shrinkage, usually 60% to 90% of the injection pressure.

Back pressure: Pressure applied during plastic plasticization, affecting plastic mixing and degassing effectiveness.

Time Control

Time control affects production efficiency and product quality:

Injection time: Time from start of injection to completion of filling, usually between a few seconds to tens of seconds.

Packing time: Time during which packing pressure is maintained until the gate solidifies.

Cooling time: Time the plastic spends cooling inside the mold, accounting for most of the entire molding cycle.

Cycle time: Total time from the start of clamping to the start of the next clamping cycle, an important indicator measuring production efficiency.

Common Process Issues and Solutions

Short Shot (Insufficient Filling)

Symptom: Incomplete product shape with some areas not filled with plastic.

Possible causes:

- Insufficient injection pressure

- Barrel temperature too low

- Gates or runners too small

- Product wall thickness too thin

Solutions:

- Increase injection pressure

- Increase barrel temperature

- Increase mold temperature

- Increase gate or runner size

Flash (Burrs)

Symptom: Excess plastic slice appearing on product edges.

Possible causes:

- Insufficient clamping force

- Injection pressure too high

- Insufficient mold manufacturing precision

- Plastic viscosity too low

Solutions:

- Reduce injection pressure

- Improve mold manufacturing precision

- Repair or replace worn molds

- Adjust process parameters or change materials

Bubbles and Silver Streaks

Symptom: Bubbles or silver-white streaks appearing inside or on the surface of the product.

Possible causes:

- Moisture in raw materials

- Barrel temperature too high

- Insufficient back pressure

Solutions:

- Reduce barrel temperature

Warpage and Deformation

Symptom: Product bends or twists after cooling.

Possible causes:

- Improper mold temperature control

– unreasonable product design

- Inappropriate process parameter settings

- Excessive material shrinkage rate

Solutions:

- Optimize cooling system design

- Improve product structure design

- Optimize process parameters

- Select appropriate materials

Process Optimization and Improvement

With technological development, injection molding processes are constantly being optimized and improved. Here are some development trends in modern injection molding technology:

Intelligent Control

Modern injection molding machines widely adopt computer control technology, enabling precise control and automatic adjustment of process parameters. Some advanced injection molding machines are also equipped with artificial intelligence systems that can automatically optimize process parameters based on real-time data during production.

Energy-saving Technology

In response to environmental protection requirements, modern injection molding machines are increasingly focusing on energy-saving designs. For example, using servo motor drives instead of traditional hydraulic drives can significantly reduce energy consumption. At the same time, optimized heating and cooling system designs can also improve energy efficiency.

Precision Molding Technology

With increasing requirements for product precision, precision injection molding technology has developed rapidly. By precisely controlling parameters such as temperature, pressure, and time, products with dimensional accuracy reaching the micron level can be produced.

New Molding Processes

In addition to traditional injection molding processes, several new molding processes are constantly emerging, such as:

Gas-assisted injection molding: Injecting gas into the plastic melt can produce hollow or partially hollow products, reducing product weight and shortening cooling time.

Two-color injection molding: Using two or more injection units can produce products with different colors or different material combinations.

Micro-injection molding: Injection technology specifically for producing micro-sized products, with product weights as small as a few milligrams.

Reaction injection molding: Mixing two or more liquid raw materials in the mold and causing chemical reactions to form solid products.

Application Cases

The injection molding process has wide applications in various industries. Here are some typical application cases:

Automotive Industry

Many components in automobiles are produced through injection molding processes, such as instrument panels, door panels, bumpers, radiator grilles, and headlight housings. These products typically require high strength, heat resistance, and weather resistance.

Electronics and Electrical Industry

Mobile phone housings, computer keyboards, display housings, connectors, switches, and other electronic and electrical products extensively use injection molding processes. These products typically require high dimensional accuracy and good appearance quality.

Medical Device Industry

Syringes, infusion sets, surgical instruments, medical equipment housings, and other medical devices widely use injection molding processes. Medical plastics require non-toxicity, odorlessness, and sterilization resistance.

Packaging Industry

Various plastic bottles, bottle caps, containers, films, and other packaging materials are mainly produced through injection or blow molding processes. These products require good sealing and printing properties.

Daily Necessities

From plastic tableware, toys, cosmetic packaging to home appliance housings, injection molding processes cover almost all kinds of plastic products in our daily lives.

The development of injection molding processes has not only changed our lifestyle but also promoted the progress of modern manufacturing. Through continuous technological innovation and process optimization, injection molding processes will continue to play an important role in the future, providing higher quality and more efficient manufacturing solutions for various industries.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.