No, die cast aluminum does not rust—but it can still corrode. Here’s the key distinction: Rust (technically “iron oxide”) only forms on ferrous metals (those containing iron, like steel or iron). Since aluminum is a non-ferrous metal (no iron content), it can’t produce rust. Instead, aluminum develops a thin, protective oxide layer when exposed to air—but under certain conditions (e.g., saltwater, acidic environments), this layer can break down, leading to corrosion.

Below, we’ll break down why die cast aluminum doesn’t rust, what causes its corrosion instead, the factors that speed up damage, and how to protect your die cast aluminum parts long-term.

Why Die Cast Aluminum Can’t Rust (But Can Corrode)

To understand this, we first clarify two critical terms:

- Rust: A red/brown iron oxide formed by the reaction of iron, oxygen, and moisture. Aluminum has no iron, so rust is impossible.

- Aluminum Corrosion: When aluminum reacts with oxygen, it forms a passive oxide layer (aluminum oxide, Al₂O₃)—just 0.00001mm thick—within seconds of exposure to air. This layer is dense, non-porous, and adheres tightly to the metal surface, acting as a natural barrier against further oxidation.

For die cast aluminum (which uses alloys like A380, ADC12, or A413), this passive layer is its first line of defense. However, the 压铸 process (high pressure, rapid cooling) and alloy additives (e.g., silicon, copper) can affect how well this layer holds up—making some die cast aluminum parts more prone to corrosion than pure aluminum.

What Causes Die Cast Aluminum to Corrode (If Not Rust)?

While the oxide layer is protective, three common scenarios can break it down, leading to visible corrosion (e.g., white/grey powdery deposits, pitting, or discoloration):

1. Exposure to Aggressive Environments

- Moisture + Salt: The biggest threat—saltwater (coastal areas, marine applications) or deicing salts (roadside equipment) react with aluminum oxide, creating soluble compounds that wash away the protective layer. For example, die cast aluminum marine hardware (e.g., boat cleats) may show white “salt corrosion” after 6–12 months of unprotected use.

- Acids/Alkalis: Industrial chemicals (e.g., cleaning agents with pH <4 or >9), acidic rain, or even certain foods (e.g., citrus juices) can dissolve the oxide layer. A die cast aluminum food processor bowl, for instance, might corrode if left in contact with lemon juice overnight.

- High Humidity: Constantly damp environments (e.g., bathrooms, outdoor sheds) slow the oxide layer’s self-repair, allowing gradual corrosion over time.

2. Alloy Composition (Silicon & Copper Matter)

Die cast aluminum isn’t pure aluminum—it’s mixed with other metals to improve strength, flowability, and castability. These additives impact corrosion resistance:

- High-silicon alloys (e.g., A380, ADC12): Silicon (5–13% content) makes casting easier but creates tiny “silicon particles” in the metal. These particles don’t bond with the oxide layer as well, leaving small gaps where moisture can seep in—causing localized pitting. A380 is common in automotive parts (e.g., engine brackets) but needs extra protection for outdoor use.

- Low-silicon/high-copper alloys (e.g., A201): Copper boosts strength but accelerates corrosion (copper acts as a “cathode” in moist conditions, drawing electrons from aluminum). These alloys are rare in outdoor parts but may corrode quickly if exposed to moisture.

- Corrosion-resistant alloys (e.g., A413): Contains magnesium (instead of copper) and less silicon, making it more durable in wet environments—often used for outdoor lighting or marine components.

3. Poor Surface Finish or Damage to the Oxide Layer

- Die casting defects: Surface flaws like porosity (tiny holes) or flash (excess metal) can trap moisture, bypassing the oxide layer. For example, a porous die cast aluminum outdoor light housing might corrode from the inside out.

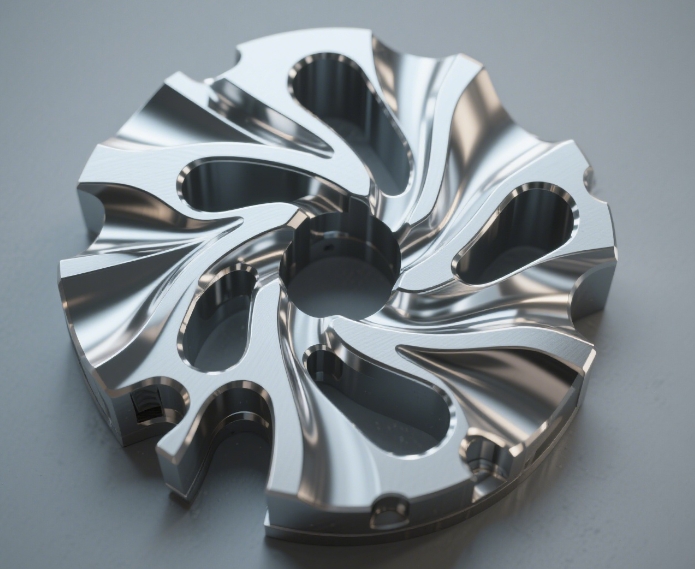

- Mechanical damage: Scratches, dents, or machining (e.g., CNC trimming) can scrape off the oxide layer. Without this barrier, fresh aluminum is exposed to air and moisture, leading to new corrosion spots.

How to Prevent Die Cast Aluminum Corrosion (5 Practical Tips)

Even though die cast aluminum doesn’t rust, protecting it from corrosion ensures longer lifespan—especially for outdoor, marine, or high-moisture applications. Here’s how:

1. Choose the Right Aluminum Alloy

Match the alloy to your environment:

- Outdoor/marine use: Opt for A413 (magnesium-enhanced) or A360 (low silicon, high corrosion resistance).

- Industrial/automotive (dry conditions): A380 or ADC12 work well (balance of strength and cost).

- Food/medical applications: A380 (food-safe) or pure aluminum (if casting allows)—avoid copper-rich alloys.

2. Apply a Protective Surface Coating

Surface treatments seal the aluminum and reinforce the oxide layer. The most effective options for die cast parts:

- Anodizing: Electrochemically thickens the oxide layer (from 0.00001mm to 0.01–0.1mm). Creates a hard, scratch-resistant finish that can be dyed (e.g., black for electronics housings). Ideal for outdoor furniture or architectural parts—lasts 10–20 years in mild climates.

- Powder Coating: Sprays a dry polymer powder (e.g., polyester) onto the part, then bakes it to form a tough, uniform layer. Resists chipping and salt corrosion—common in automotive wheels, outdoor grills, or garden tools.

- Electroplating: Coats the aluminum with a thin layer of corrosion-resistant metal (e.g., chrome, nickel, or zinc). Used for decorative parts (e.g., faucet handles) or high-wear components.

- Ceramic Coating: A thin, heat-resistant layer that works for high-temperature parts (e.g., engine components) while preventing corrosion.

3. Design for Corrosion Resistance

Work with your die caster to avoid moisture traps:

- Add drainage holes: For parts that hold water (e.g., outdoor light housings), drill small holes to let moisture escape.

- Smooth surfaces: Minimize porosity by optimizing die design (e.g., proper venting, slower cooling) to reduce trapped air.

- Avoid sharp edges: Sharp corners can chip easily, damaging the oxide layer—use rounded edges instead.

4. Regular Maintenance

For existing die cast aluminum parts:

- Clean gently: Wipe with a mild soap and water (avoid harsh chemicals like bleach or ammonia) to remove salt, dirt, or grime.

- Touch up damage: If the coating scratches, use a matching touch-up paint (for powder coating) or clear sealant (for anodizing) to cover exposed aluminum.

- Apply a protective spray: For outdoor parts, use a silicone-based or wax sealant every 6–12 months to boost water resistance.

5. Use Corrosion Inhibitors (For Industrial Applications)

In harsh environments (e.g., chemical plants, marine engines), add corrosion inhibitors to coolants or lubricants. These chemicals (e.g., chromates, silicates) bond to the aluminum surface, reinforcing the oxide layer and preventing chemical attack.

Real-World Example: Die Cast Aluminum in Outdoor Lighting

A manufacturer of outdoor LED fixtures switched from A380 (uncoated) to A413 (with powder coating) after customers reported white corrosion on fixtures in coastal areas. The change reduced corrosion claims by 90%—and the powder coating added only $0.50 per unit to the cost (a small investment for 15+ years of lifespan).

When to Worry About Die Cast Aluminum Corrosion

Corrosion is rarely a problem if:

- The part uses a corrosion-resistant alloy (e.g., A413) or has a protective coating (e.g., anodizing).

- It’s used in dry, mild environments (e.g., indoor electronics housings, office furniture).

You should take action if:

- The part is exposed to saltwater, high humidity, or chemicals.

- You notice white/grey powder, pitting, or discoloration (signs the oxide layer is failing).

Final Takeaway

Die cast aluminum doesn’t rust—but it can corrode if unprotected. The key to long-lasting parts is choosing the right alloy, adding a protective coating, and designing to avoid moisture traps. For high-risk applications (e.g., marine, outdoor), invest in corrosion-resistant treatments—they’ll save you money on replacements and repairs down the line.

Have a specific die cast aluminum project? Leave a comment with your application (e.g., “outdoor furniture” or “marine part”), and we’ll help you pick the best alloy and coating!