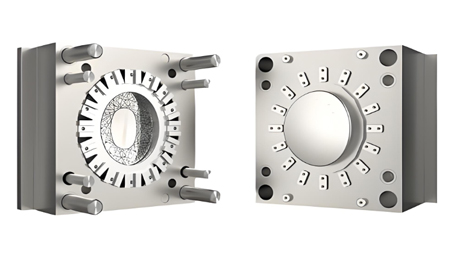

The children’s toy in your hand, the car dashboard, even the component casings of Mars rovers—they might all originate from the same “magic box”: the injection mold. Like a silent creator, it transforms molten plastic into countless forms in an instant, from 0.1-gram micro gears to 2-ton logistics pallets, from millimeter precision in medical needles to artistic curves in household items. Today, we unveil the secrets of this “industrial magic.” It’s not just about cold steel and scorching plastic—it embodies humanity’s relentless pursuit of “perfect replication.” Whether you aim to create a viral water bottle or produce medical devices with million-level precision, this story will redefine your imagination of manufacturing.

Main Content

1. What Is an Injection Mold? — The Replication Master of Industrial Civilization

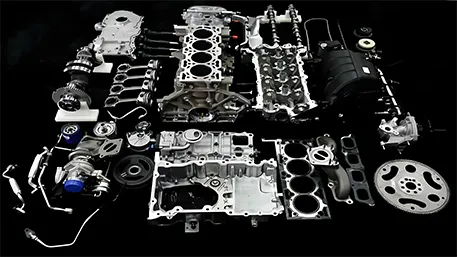

An injection mold is not just a block of steel but a precise “space-time controller.” Its working principles resemble a symphony of fire and ice:

- High-Temperature Melting: Plastic pellets are heated to 200–300°C (akin to volcanic lava) and transformed into a viscous fluid.

- High-Pressure Injection: The molten plastic is forced into the mold cavity at 150–300 MPa (three times the pressure of the deep sea at 3,000 meters).

- Instant Solidification: Cooling systems solidify the melt in 10–30 seconds, freezing intricate details like a paused moment in time.

The global injection mold market has surpassed $102.4 billion (2025 data from Grand View Research). From Coca-Cola bottles to iPhone casings, 90% of plastic products rely on this technology. The true revolution? What was once exclusive to mass production now enables “one-piece orders” through flexible manufacturing.

2. Custom Injection Mold Manufacturing: The Superbridge from Idea to Mass Production

▎Game-Changer for Small-Batch Customization

At a maternal-infant brand in Dongguan, designers used our mold flow analysis system to validate the sealing performance of 12 bottle designs in just 5 days. The final mold achieved a lifespan of 500,000 cycles, reducing per-unit costs to one-third of traditional methods. This “fast iteration–precision production” capability empowers startups to compete in high-end manufacturing.

▎Data-Driven Value Leap

- Complex Structures: Molds for 0.05mm ultra-thin medical catheters (equivalent to A4 paper thickness).

- Energy Revolution: Hot runner technology cuts material waste by 30%, reducing plastic waste by 800 tons annually.

- Efficiency Myth: 72 hours from 3D design to first trial mold (industry average: 7 days).

3. Material Universe: The Gene Pool of Injection Molds

Our “material galaxy” spans 6 categories and 218 engineering plastics, meeting demands from extreme environments to daily life:

| Material Family | Star Player | Extreme Performance | Iconic Use Cases |

|---|---|---|---|

| General Warrior | ABS | Impact strength: 35 kJ/m² | LEGO bricks, luggage shells |

| Medical Expert | PEEK | Withstands 300°C steam sterilization | Orthopedic screws, endoscope parts |

| Transparent Elf | PMMA | 92% light transmittance (like glass) | Car light lenses, acrylic bathtubs |

| Green Pioneer | PLA Bioplastic | 90% decomposition in 180 days | Eco-friendly cutlery, sutures |

For specialized needs, we offer “material+” solutions. For example, glass-fiber-reinforced PA66 in automotive grille molds boosts tensile strength by 400% while reducing weight by 20%.

4. Technical Core: The Nine Layers of Precision

▎Equipment Matrix: The Evolution of Steel Giants

Our 1,000-ton injection machines feature AI vision systems, giving them “eagle eyes”:

- Real-Time Monitoring: Captures melt flow anomalies in 0.01 seconds.

- Smart Parameter Adjustment: Auto-optimizes pressure curves based on environmental conditions.

- Self-Healing: Predictive maintenance cuts downtime by 70%.

▎Process Innovations:

- Microcellular Foaming: Creates honeycomb structures, reducing weight by 30% without sacrificing strength.

- Two-Shot Molding: Produces soft-grip tool handles in a single cycle.

- Gas-Assisted Molding: Forms hollow channels in AC panels, saving 40% material.

5. Marketing Revolution: Turning Manufacturing into Tangible Stories

Our “Cloud Factory” experience lets clients:

✅ Co-Design Online: Modify cooling channels via AR previews.

✅ Track Production: Watch molds being crafted via 5G livestreams.

✅ Visualize Carbon Footprints: Convert saved petroleum into forestation metrics.

On Bilibili, our documentary 108 Days of a Mold surpassed 5 million views. When viewers witnessed 20-ton steel blocks transform in five-axis machining centers, the screen flooded with comments: “This is hardcore romance!”

6. Precision Battle: The Micron-Level Race

Our four-dimensional precision system ensures:

| Precision Aspect | Control Technology | Performance Data |

|---|---|---|

| Dimensional Accuracy | Laser calibration + thermal compensation | ±0.005mm (exceeds ISO 1) |

| Surface Finish | Mirror EDM | Ra0.1μm (reflects facial contours) |

| Lifespan | Nano-coating | Mold life extended 2–5x |

A drone manufacturer using our high-precision molds reduced propeller balance errors from 0.3g to 0.05g, boosting flight stability by 40%—a triumph of technology and a dance with physical limits.

7. Q&A: Demystifying Injection Molding

Q: Is mold cost feasible for 500 custom planters?

A: Our “shared cavity” solution slashes costs to 1/3 of industry standards, supporting unlimited design tweaks.

Q: How to eliminate flow marks on transparent parts?

A: “Ultra-slow injection + mold temp oscillation” ensures crystal clarity—5mm/s flow rate ±1°C precision.

Q: How to prevent design theft?

A: Triple shield:

① Blockchain-stored designs

② Invisible anti-counterfeit codes

③ Post-delivery data destruction

As you read this, you might be using an injection-molded phone stand or sitting on an office chair with molded cushions. This is not just a dance of plastic and steel but humanity’s eternal quest to perfect replication.