In the precision world of industrial manufacturing, every component carries the important mission of ensuring stable equipment operation. As a national high-tech enterprise with 26 years of dedicated experience, Xiamen Goldcattle Industrial & Trade Co., Ltd. has become a trusted custom parts supplier for global customers, providing high-quality CNC mechanical parts customization services for various industries.

I. Professional Strength, Forging the Foundation of Quality

Goldcattle boasts an experienced and highly skilled professional team, including industrial designers, mold engineers, and CNC programming experts. The company 始终 adheres to the business philosophy of “high quality, high efficiency, integrity service” and is committed to providing customers with one-stop solutions from design to production.

Advanced Equipment Guarantee

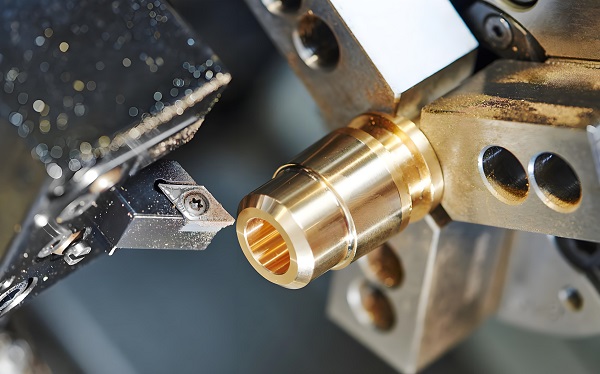

The company is equipped with over 100 professional processing and quality inspection equipment, covering various CNC machining centers and precision testing instruments, ensuring that every part meets customers’ strict requirements. From milling, turning to drilling, boring, from multi-axis machining to EDM processing, Goldcattle has complete processing capabilities to handle customization needs for various complex structures.

Strict Quality Control

As an ISO 9001 certified enterprise, Goldcattle has established a comprehensive quality management system. Each processing 环节 undergoes professional quality inspection to ensure products meet international standards. The company also holds multiple international certifications such as SGS, RoHS, CE, providing reliable quality assurance for global customers.

II. Diverse Materials, Adapting to Various Needs

Goldcattle offers a rich selection of materials and can customize the most suitable CNC mechanical parts for customers according to the requirements of different industries and application scenarios:

Metal Material Series

- Aluminum Alloy: Lightweight and high strength, with good thermal conductivity and corrosion resistance, suitable for aerospace, automotive manufacturing and other fields

- Stainless Steel/Carbon Steel: High strength and good wear resistance, widely used in key components of construction machinery, medical equipment, etc.

- Copper/Brass: Excellent electrical and thermal conductivity, often used in core components of electronic equipment and precision instruments

Non-metal Material Series

- Engineering Plastics: Lightweight and good insulation properties, suitable for electronic housings, medical devices, etc.

- Rubber Products: Good sealing performance and shock absorption effect, used in various seals and shock absorption devices

III. Full-process Customization, Seamless Service Connection

Goldcattle has established a standardized customization service process to ensure smooth and efficient operation of every link from demand communication to product delivery:

1. Demand Consultation and Program Design

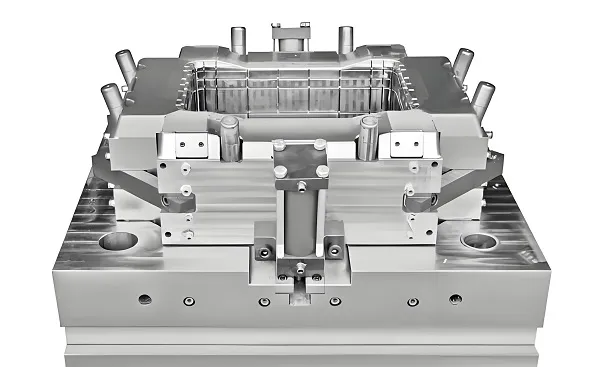

Customers only need to provide drawings or samples, and Goldcattle’s professional engineering team will conduct in-depth demand analysis and develop detailed processing plans, including process selection, material recommendations, cost budget, etc., to ensure the feasibility and economy of the plan.

2. Factory Quotation and Sample Confirmation

Based on the design plan, Goldcattle provides transparent quotations. Before formal mass production, the company will first produce samples for customer confirmation to ensure that the dimensional accuracy and appearance quality of the products fully meet the requirements.

3. Mass Production and Quality Assurance

After sample confirmation, Goldcattle will start mass production. Advanced production equipment and strict quality control system ensure that every product meets consistent high-quality standards.

4. Logistics Delivery and After-sales Service

After production is completed, Goldcattle provides flexible logistics solutions to ensure timely delivery of products. The company also provides comprehensive after-sales service to solve any problems customers encounter during use.

IV. Wide Application, Empowering Industry Development

Goldcattle’s CNC mechanical parts customization service has been successfully applied in multiple industries, creating significant value for customers:

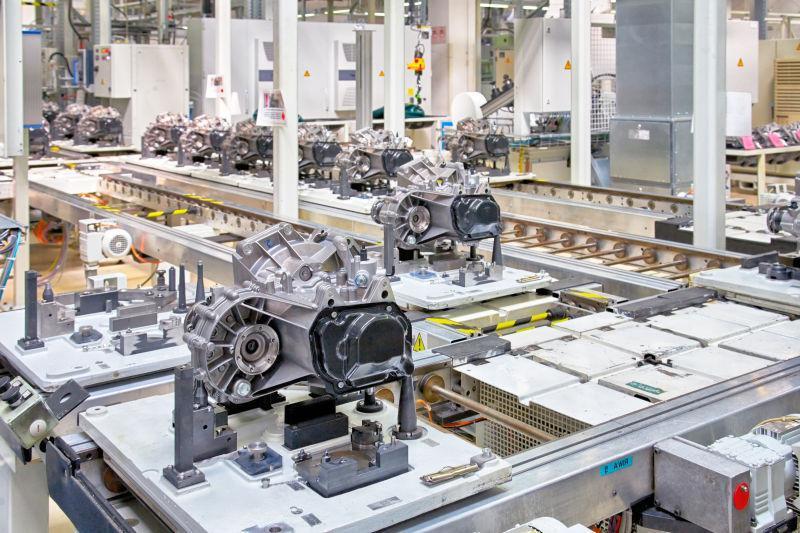

Automotive Manufacturing Field

Customizing precision engine components and transmission system parts for automotive manufacturers, improving vehicle performance and reliability.

Construction Machinery Field

Providing high-strength, wear-resistant mechanical parts to ensure stable operation of construction machinery in harsh environments.

Electronic Equipment Field

Customizing high-precision electronic housings and heat dissipation components to meet the precision and reliability requirements of electronic equipment.

Medical Device Field

Producing precision parts that meet medical standards, providing guarantee for the safety and accuracy of medical equipment.

Aerospace Field

Manufacturing lightweight and high-strength aerospace components, supporting the development of aerospace technology.

V. Win-win Cooperation, Creating the Future Together

Goldcattle is not only a parts supplier but also a partner of customers. Adhering to the tenet of “sustainable operation, customer first”, the company has established long-term and stable cooperative relationships with over 100 partners worldwide.

Customer Testimonials

Many internationally renowned enterprises choose Goldcattle as their CNC mechanical parts supplier. Customers’ trust stems from Goldcattle’s consistent high-quality products and professional services. Whether it is small precision parts or large complex components, Goldcattle can provide satisfactory solutions.

Future Outlook

With the in-depth development of Industry 4.0, Goldcattle will continue to invest in research and development, introduce more advanced equipment and technology, and enhance the capabilities and level of customization services. The company will always adhere to customer demand-oriented, with technological innovation as the driving force, to provide global customers with higher quality CNC mechanical parts customization services.

Conclusion

On the path of precision manufacturing, Goldcattle has gone through 26 years. These 26 years of accumulation and precipitation have forged the company’s professional strength in the field of CNC mechanical parts customization. Whether it is standardized products or personalized customization, Goldcattle can create greater value for customers with exquisite craftsmanship, strict quality, and professional services.

Choosing Goldcattle means choosing professionalism, quality, and peace of mind. Let us work together to customize your industrial future with precision manufacturing technology!