If you want to achieve high precision in CNC machining parts, here are some key steps and considerations:

1. Start with a detailed design: Ensure that the part design is precise and includes all necessary dimensions, tolerances, and surface finish requirements. Use CAD software to create accurate 3D models.

2. Select the right materials: Choose materials that have consistent mechanical properties and low variations. Materials with good machinability, such as certain grades of aluminum alloys or tool steels, can contribute to better precision.

3. Optimize the machining process:

- Use high-quality cutting tools specifically designed for the material and the machining operation.

- Determine the appropriate cutting speeds, feed rates, and depths of cut through experimentation and reference to machining handbooks.

- Employ multi-axis machining when necessary to access complex geometries and improve surface finish.

4. Ensure proper fixturing: The part must be securely held in place during machining to prevent movement or vibration. Custom fixtures or vacuum chucks can provide stable support.

5. Implement temperature control: Minimize the effects of heat generated during machining, as it can cause thermal expansion and affect precision. Use coolant or coolant mist systems effectively.

6. Regular machine maintenance: Keep the CNC machine in top condition by performing routine maintenance, including calibration of axes, checking spindle accuracy, and maintaining tool changers.

7. Quality control and inspection: Use precise measuring tools like coordinate measuring machines (CMMs) to verify the dimensions and tolerances of the machined parts.

8. Skill and experience of the operator: A well-trained and experienced operator can make adjustments on the fly to optimize the machining process and ensure high precision.

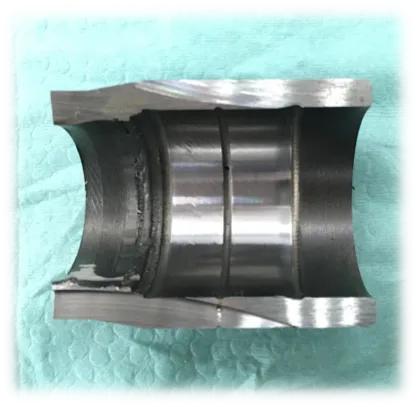

9. Post-processing operations: Sometimes, additional processes like grinding, honing, or polishing may be required to achieve the final desired surface finish and precision.

By following these steps and paying attention to detail throughout the process, you can increase the chances of obtaining high-precision CNC machined parts.