1、Answer

CNC machines cut by using computer-controlled tools (e.g., end mills, drills, lathe tools) that move along precise paths defined by G-code. The machine’s motors drive the tools or workpiece to remove material through rotary cutting (milling), linear cutting (lathes), or abrasive processes (grinding). Speed, feed rate, and tool type are optimized for the material (e.g., metal, plastic) to achieve accurate shapes and finishes.

2、Expansion

Core Cutting Mechanisms in CNC Machines

-

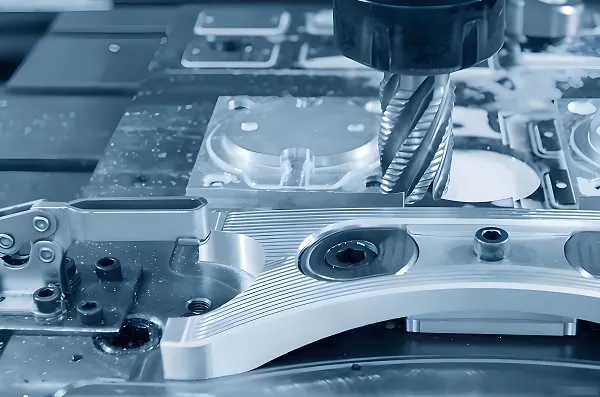

Milling: Rotary Cutting with Multi-Tooth Tools

- A spinning cutter (e.g., end mill, ball nose mill) removes material through lateral or plunge movements. For example:

- A 3-flute end mill might rough-cut a steel bracket at 2000 RPM, removing 2mm of material per pass, then switch to a 5-flute mill for a smooth finish at 5000 RPM.

- 3-axis vs. 5-axis milling: 5-axis machines tilt the tool or workpiece, enabling undercuts and complex curves (e.g., sculpting a dental crown from a ceramic block).

- A spinning cutter (e.g., end mill, ball nose mill) removes material through lateral or plunge movements. For example:

-

Turning/Lathe: Rotating Workpiece, Stationary Tool

- The workpiece spins (e.g., a steel rod in a lathe chuck), while a fixed cutting tool moves linearly to shape it. Common operations include:

- Facing: Cutting the end surface to create a flat face.

- Taper turning: Shaping a conical surface (e.g., a stair railing post).

- Thread cutting: Using a threading tool to create screw threads (e.g., on a bolt).

- Example: A CNC lathe might turn a 50mm-diameter aluminum rod into a piston with a 30mm-diameter cylinder in one automated setup.

- The workpiece spins (e.g., a steel rod in a lathe chuck), while a fixed cutting tool moves linearly to shape it. Common operations include:

-

Drilling and Boring: Creating Holes

- Drills create cylindrical holes (e.g., a 6mm hole for a bolt), while boring bars enlarge existing holes for precision (e.g., a 10mm hole bored to 10.02mm for a press-fit bearing).

- Peck drilling: Used for deep holes (e.g., 100mm in steel), where the drill retracts periodically to clear chips and prevent overheating.

-

Abrasive Cutting: Grinding and EDM

- Grinding: Uses a rotating abrasive wheel to refine surfaces (e.g., a CNC surface grinder smoothing a stainless steel plate to a Ra 0.8μm finish).

- Electrical Discharge Machining (EDM): For hard materials (e.g., tungsten carbide), an electrode releases electrical sparks to erode material, ideal for intricate molds or turbine blades.

-

Specialized Cutting for Non-Metals

- Routing: In CNC routers, spiral bits cut wood, foam, or plastic (e.g., carving a sign from MDF with 0.1mm precision).

- Laser/Plasma Cutting: Used in CNC laser machines to melt or vaporize materials (e.g., cutting 2mm acrylic with a CO₂ laser for signage).

Key Factors Influencing Cutting Performance

- Material Properties:

- Hard materials (e.g., titanium) require slower speeds and robust tools (e.g., carbide end mills).

- Soft materials (e.g., aluminum) allow faster feeds (e.g., 1000mm/min) and higher spindle speeds (15,000 RPM).

- Tool Geometry:

- A helical flute angle (e.g., 30°) in end mills improves chip evacuation for sticky materials like stainless steel.

- Coatings (e.g., TiN, DLC) reduce friction and extend tool life (e.g., a TiN-coated drill lasts 3x longer in cast iron).

- Coolant Strategies:

- Flood cooling with oil cools tools in steel machining; mist cooling or air is used for non-ferrous metals to avoid residue.

Automation and Safety in Cutting

- CNC machines use tool changers (e.g., 20-tool magazines) to switch automatically between operations, reducing manual intervention.

- Safety features like enclosure doors, emergency stops, and chip guards protect operators from flying debris and rotating tools.

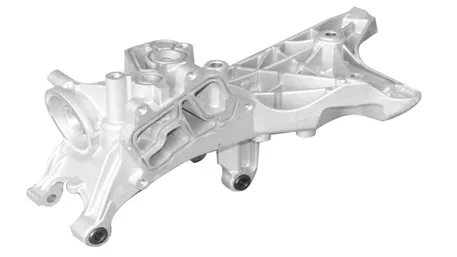

By combining precise motion control, tooling versatility, and material-specific parameters, CNC machines achieve repeatable, high-precision cutting across industries—from automotive engine parts to intricate jewelry components.