Answer

Machining brass is relatively easy. Brass has a low hardness. The commonly used free – cutting brass C36000 has a hardness of 63 – 126HB, and the lead in lead – containing brass acts as a self – lubricant, reducing tool wear. When using carbide tools for machining, the cutting speed can reach 2000 surface feet per minute, and a surface finish of Ra≤1.6μm can be obtained. The chips produced during brass cutting are short and easy to handle, and are not likely to clog the tool. However, specific grades such as lead – free brass need parameter adjustments during machining due to their slightly higher hardness. Overall, the machining difficulty of brass is low, and it is regarded as a benchmark material for machinability.

Extended Answer

I. Influence of Brass Material Properties on Machining

Relationship between Chemical Composition and Properties

Brass is a copper – zinc alloy, with the zinc content generally ranging from 5% to 45%. The zinc content directly affects its hardness and strength. The higher the zinc content, the higher the hardness and strength of brass, but the plasticity will decrease to some extent. For example, C28000 brass with 40% zinc content has higher strength, while C23000 brass with 15% zinc content is easier to form. In addition, some brasses contain 1.5% – 3.7% lead, forming free – cutting brass (such as C36000). Lead, as a solid lubricant, greatly improves the cutting performance of brass.

Characteristics of Mechanical Properties

Hardness: The hardness of common brass grades ranges from 63 – 126HB. Compared with steel (about 200HB) and stainless steel, the hardness of brass is significantly lower, which means that less force is required for the tool to cut into the material.

Tensile Strength: The annealed C36000 brass has a tensile strength of 338 – 469MPa, which can withstand the cutting force without premature fracture or deformation.

Ductility: Some brasses, such as C26000, have an elongation of 30%, which is suitable for forming complex shapes through cold working. However, work – hardening problems need to be noted during the machining process.

II. Machining Differences among Different Brass Alloy Grades

Free – cutting Brass (Taking C36000 as an Example)

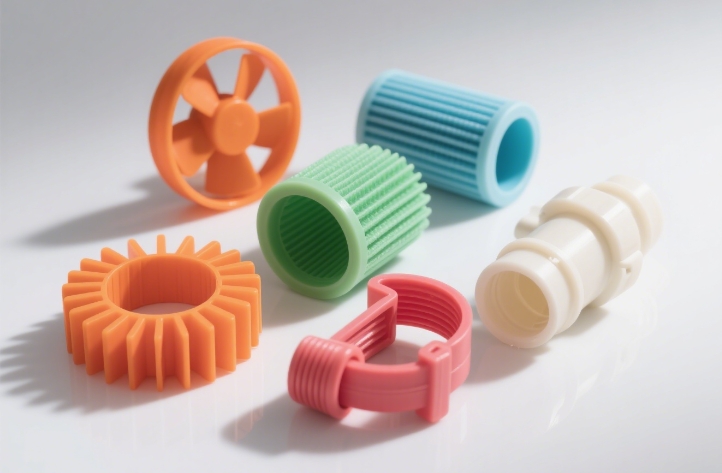

C36000 is the most commonly used free – cutting brass, with a lead content of 2.5% – 3.7%. Its machinability index is defined as 100%, serving as a benchmark for measuring the machinability of other materials. It can be processed at high speeds. When using carbide tools, the cutting speed can reach 2000 surface feet per minute (SFM), and a surface finish of Ra≤1.6μm can be ensured. It is often used to manufacture precision parts such as screws, valves, and electronic connectors.

Admiralty Brass (C46400)

Admiralty brass contains 0.75% tin, which has good seawater corrosion resistance and is often used to manufacture marine propellers and pipe fittings. Although its hardness is slightly higher than that of C36000 (HB 120 – 150), it can still maintain about 90% of the machinability of C36000. Only slight adjustments to the cutting parameters are needed during machining.

Lead – free Brass (Such as C69300)

To meet environmental protection standards such as RoHS, lead – free brass uses bismuth or silicon to replace lead. The hardness of this type of brass is 100 – 130HB. The cutting speed needs to be reduced by 10% – 15% during machining, but it can still achieve about 90% of the surface machining quality of C36000, and is suitable for the processing of medical and food – contact products with high environmental protection requirements.

III. Machining Processes and Parameter Optimization

Tool Selection

Tool Materials: Carbide tools (such as carbide coated with TiN or DLC) are the first choice for machining brass. Compared with high – speed steel (HSS) tools, their service life can be extended by 3 – 5 times. When continuously machining C36000 brass, carbide tools can run for more than 8 hours without re – grinding.

Tool Geometric Shapes: A positive rake angle of 8 – 15° and a sharp cutting edge can effectively reduce the cutting force. When machining threads, a tool with a 60° angle and a chip – breaking groove can prevent material smearing.

Setting of Cutting Parameters

Turning: When using carbide tools, the cutting speed is 300 – 900SFM, the feed rate is 0.05 – 0.15mm/rev, and the depth of cut is controlled at 2 – 5 times the feed rate to achieve the best chip – breaking effect.

Milling: The cutting speed is 200 – 600SFM, the feed per tooth is 0.03 – 0.12mm. For finish machining, the axial depth of cut is 0.5 – 2mm, and for rough machining, it can be increased to 6mm.

Drilling: Use a standard 118° twist drill, with a cutting speed of 150 – 400SFM. For deep holes with a depth more than 5 times the diameter, the peck – drilling method should be used to assist chip removal.

Cooling and Lubrication

Coolant: A water – soluble emulsion with a concentration of 5% – 10% can effectively reduce friction and cutting heat. In deep – hole drilling, using mineral oil can improve the surface finish. For the machining of marine brass parts, using high – pressure coolant of 5 – 10MPa can enhance chip – removal ability.

Dry Machining: In the case of low – load machining, dry machining can be adopted. For example, dry – turning C36000 brass at a speed of 600SFM and cooling with compressed air can reduce the cost of coolant use and waste – liquid treatment problems.

IV. Common Machining Challenges and Countermeasures

Formation of Built – up Edge (BUE)

Cause: During the cutting process, high temperature and high pressure cause the brass material to adhere to the tool edge, forming a built – up edge, which affects the machining surface quality.

Solution: Increase the cutting speed to reduce the contact time between the material and the tool. For example, increase the cutting speed of C36000 brass to 1000SFM. Coat the tool surface with a PVD coating (such as TiAlN) to enhance the lubricity and wear resistance of the tool surface.

Long Chip Entanglement

Cause: Brass grades with good plasticity (such as C26000) are prone to producing continuous long chips during machining, which entangle the tool or workpiece, affecting machining accuracy and safety.

Solution: Set chip – breaking grooves on the tool or use a serrated cutting edge to force the long chips to break. Adjust the feed rate and cutting speed parameters to make the chips break due to stress concentration during the formation process.

Work – hardening

Cause: During cold working, the grain structure of brass changes, increasing its hardness and strength while reducing its plasticity and toughness, making subsequent machining more difficult.

Solution: Anneal the work – hardened brass parts. Heat them to 260 – 320°C and hold for 1 hour to restore the plasticity and machinability of the material.

V. Comparison of Machining Difficulty with Other Materials

Comparison with Steel

The machinability index of steel (such as 45 – steel with a hardness of about 200HB) is only 20%. Compared with brass, steel has a higher hardness, the tool wears faster during cutting, requires a lower cutting speed (usually 50 – 200SFM) and greater cutting force, and the machining efficiency is much lower than that of brass. In addition, iron chips are likely to stick during the machining of steel, while brass chips are easier to handle.

Comparison with Aluminum Alloy

Although aluminum alloy has a low density and low hardness (about 30HB), it is prone to tool – sticking during machining, forming a built – up edge, resulting in deterioration of surface roughness. Its machinability index is 60%. Although it is higher than that of steel, it is still lower than that of brass. Aluminum alloy machining requires a higher cutting speed (600 – 1800SFM) and frequent tool changes, resulting in a relatively high comprehensive processing cost.

VI. Development Trends of Brass Machining

Research and Development of New Materials

Graphene – reinforced Brass: By adding graphene to enhance the properties of brass, the tensile strength of brass can be increased by 30%, the thermal conductivity can be increased by 20%, and good machinability can be maintained at the same time, which is suitable for the manufacture of high – end heat – dissipation and wear – resistant parts.

High – strength Lead – free Brass: Develop lead – free brass with a hardness of 120 – 150HB and a lead content of less than 0.5%. While meeting environmental protection requirements, it can maintain a machinability close to that of C36000.

Innovation of Machining Technologies

Artificial Intelligence – driven Machining Optimization: Use machine – learning algorithms to analyze brass machining data, predict the best cutting parameters, reduce trial – and – error time, and increase machining efficiency by more than 50%.

Robotic Automated Machining: Use collaborative robots (cobots) combined with force sensors to achieve automated deburring and surface treatment of brass parts, with an accuracy of up to 99.9%.

Sustainable Machining

Closed – loop Recycling System: The waste recovery rate of modern brass foundries exceeds 97%. Compared with the production of primary brass, energy consumption is reduced by 62%, reducing the impact on the environment.

Environment – friendly Surface Treatment: Use Ni – P – TiO₂ nano – composite coatings without heavy metals to provide more than 1000 hours of salt – spray corrosion protection for brass parts, replacing traditional chromium – containing coating processes.