Answer:

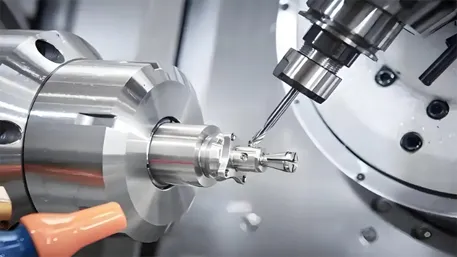

There is no fixed value for the time required for CNC milling. It mainly depends on factors such as the complexity of the part, the hardness of the material, the performance of the cutting tool, the cutting parameters, and the performance of the equipment. Simple planar or groove machining may only take a few minutes. For complex curved surfaces, high-precision parts, or machining of hard materials, it may take several hours or even several days. In mass production, due to fixture reuse and program reuse, the processing time per piece will be shortened.

Extension

I. The Correlation between Part Structure Complexity and Processing Duration

The complexity of the part structure directly determines the number of machining processes and the difficulty of path planning in CNC milling. Simple parts such as regular planes and straight grooves only require a single or a small number of machining processes, and the tool path planning is simple, so the milling time is short. For example, for rectangular plane milling, it can usually be completed in one or several passes, which may take less than 10 minutes. However, for complex parts, such as the blades of an aero – engine, which have twisted three – dimensional surfaces, thin – walled structures, and fine film holes, multi – axis linkage machining is required, involving multiple processes such as roughing, semi – finishing, and finishing. The tool path needs to be carefully planned according to the surface curvature to avoid interference and ensure accuracy. Just the surface milling of the blade may take dozens of hours, and with the processing of other features, the total duration can reach several days. In addition, special structures such as undercuts and deep cavities on the part also require the use of special tools and processing strategies, further increasing the processing time.

II. The Impact of Material Properties on Processing Efficiency

The properties such as hardness, strength, and toughness of different metal materials significantly affect the cutting speed and tool durability in CNC milling. For hard materials such as titanium alloys and nickel – based superalloys, the tool wears quickly during cutting. To ensure tool life and machining accuracy, the cutting speed and feed rate need to be reduced, resulting in a significant increase in processing time. For example, when milling titanium alloy parts, the cutting speed is usually controlled at 30 – 60m/min. In contrast, for aluminum alloys (the cutting speed can reach 200 – 300m/min), the processing efficiency is much lower. For parts of the same size, milling titanium alloy may take 3 – 5 times as long as milling aluminum alloy. In addition, the thermal conductivity of the material also affects the processing time. For materials with poor thermal conductivity, such as stainless steel, the cutting heat is not easy to dissipate, which easily causes the tool to overheat and requires frequent shutdowns for cooling, thus prolonging the processing cycle. For some composite materials, such as carbon – fiber – reinforced composites, although their hardness is not high, due to their anisotropy and fiber – reinforced characteristics, defects such as delamination and tearing are likely to occur during cutting. Special cutting parameters and tools need to be used, which also increases the processing time.

III. Optimization Strategies for Tools and Cutting Parameters

The selection of tools and the setting of cutting parameters directly affect the milling efficiency. The right type of tool can significantly increase the processing speed. For example, when machining deep grooves, using a large – diameter end – mill can reduce the number of passes; for machining curved surfaces, a ball – nose mill can better fit the contour. The material of the tool is also crucial. Carbide tools have good wear resistance and are suitable for high – speed milling of general metal materials. PCD (polycrystalline diamond) tools can work at higher cutting speeds and feed rates when machining aluminum alloys and non – metallic materials, greatly shortening the processing time. Regarding cutting parameters, the cutting speed, feed rate, and cutting depth need to be considered comprehensively. Increasing the cutting speed and feed rate can accelerate the material removal rate, but it will exacerbate tool wear and even affect machining accuracy. Increasing the cutting depth can reduce the number of passes, but too large a cutting depth may cause excessive cutting force, leading to vibration and tool damage. Therefore, according to the material, tool, and part requirements, the parameter combination needs to be optimized through experiments or empirical formulas to shorten the processing time as much as possible while ensuring processing quality.

IV. The Role of Equipment Performance and Processing Modes

The performance of CNC machine tools, such as spindle speed, feed speed, positioning accuracy, and rigidity, has a significant impact on milling efficiency. High – speed machining centers can have a spindle speed of over 20,000r/min. With a fast – feed system, high – speed cutting can be achieved. Compared with ordinary machine tools, the processing time can be shortened by 30% – 50%. If the machine tool has good rigidity, it can withstand greater cutting forces, allowing the use of larger cutting parameters and further improving efficiency. In addition, the processing mode also affects the duration. During single – piece processing, frequent clamping, tool setting, and program debugging are required. In batch processing, multiple workpieces are clamped at one time, or group technology is used to reuse the programs of similar parts, which can significantly reduce the auxiliary time and improve the overall processing efficiency. At the same time, machine tools with a high degree of automation, equipped with an automatic tool – changing system and a pallet – changing system, can achieve continuous processing, which also helps to shorten the processing cycle.