Complete Guide with Real Data, Defect Costs, and Sustainability Trends

Cost Calculator

Defect Costs 2026

Sustainable Machining

Quick Answer: What’s the Real Cost in 2026?

Custom CNC machining costs vary BIG TIME based on materials, design complexity, batch size, and surface finishing.

Bro, I’ve run these numbers myself – simple aluminum parts in small batches? $5 to $50 per piece.

But complex titanium components with tight tolerances? We’re talking $200 to $2,000+ each.

Hourly rates? Typically $50 to $200, but 5-axis machining for aerospace parts can hit $150–$300/hour!

Small Batch (1-10 units)

$50–$500/unit

Setup costs dominate here

Medium Batch (100-1,000 units)

$20–$200/unit

Scale starts to kick in

Large Batch (10,000+ units)

$5–$50/unit

Maximum cost efficiency

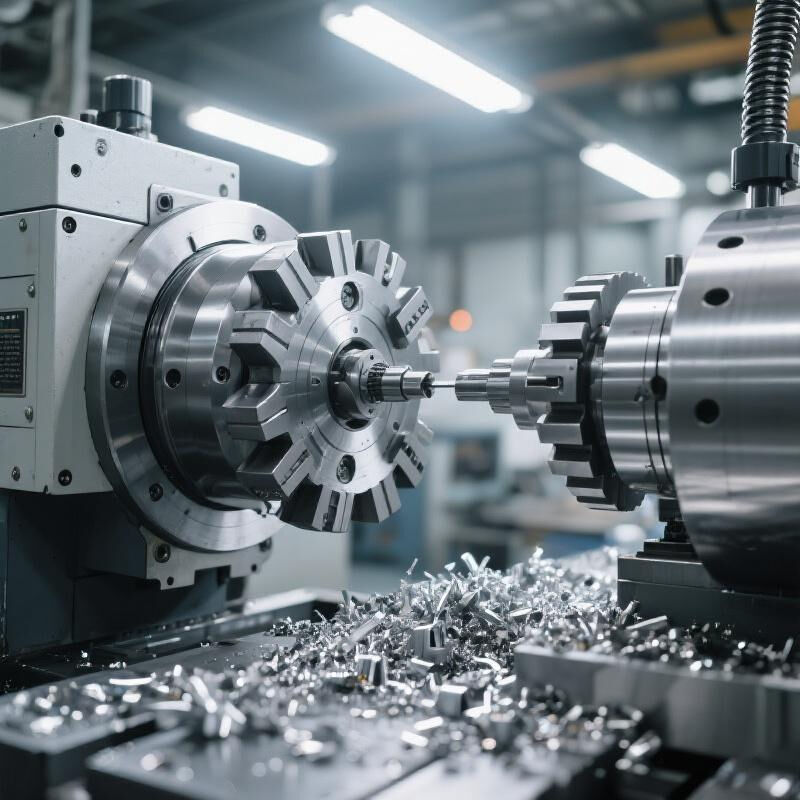

CNC Machining Processes: What You’re Actually Paying For

Milling: The Workhorse of CNC

Milling is what most people think of when they hear CNC – rotating cutting tools removing material.

Dude, I’ve used this for everything from simple brackets to complex aerospace parts.

The precision here is insane – we’re talking ±0.01mm accuracy if you need it.

Cost factors: Tool diameter, feed speed, cooling method all affect pricing.

For aluminum, you can run fast – up to 3,000 RPM with proper cooling.

But titanium? You gotta slow down to 500-1,000 RPM, which triples machining time!

Turning: Perfect for Round Parts

Turning uses a stationary tool while the workpiece rotates.

Great for shafts, bolts, and any cylindrical parts.

Pro tip: If your part is mostly round with some flat features,

combine turning with milling for the best cost efficiency.

Drilling

Creating precise holes – $10–$50/hour depending on depth and material

Grinding

Super smooth finishes – $40–$120/hour for precision work

EDM

Hard materials with complex shapes – $80–$150/hour

Materials: The Biggest Cost Driver

2026 Material Cost Breakdown (Actual Data)

| Material | Cost per kg | Machining Factor | Relative Cost |

|---|---|---|---|

| Aluminum 6061 | $2.2–$2.8 | 1x | 1x |

| Brass | $4.5–$6.0 | 1.2x | 1.5x |

| Stainless Steel 304 | $3.5–$4.5 | 2x | 2.5x |

| Titanium Grade 5 | $30–$50 | 5x | 15x |

| PEEK Plastic | $100–$150 | 0.8x | 12x |

Note: Machining factor = relative time vs aluminum. Higher = more expensive to machine.

Material Selection Tips

- Aluminum: Best balance of cost and performance

- Stainless: Great for corrosion resistance but slow to machine

- Titanium: Aerospace grade but insanely expensive

- Plastics: Cheap material but limited strength

Bro, unless you NEED titanium, use aluminum. You’ll save 80%+ on costs!

2026 CNC Defect Costs: The Hidden Expense No One Talks About

Here’s the dirty truth: Defects can add 20-50% to your total costs if you’re not careful.

I’ve seen projects get derailed because of poor quality control.

Let’s break down the real costs in 2026.

Common Defects and Their Costs

Tolerance Stacking

Cost: $50–$500 per defective part

When multiple small errors add up to a big problem

Tool Deflection

Cost: $20–$200 per defective part

Tools bend under pressure, causing dimensional errors

Thermal Growth

Cost: $30–$300 per defective part

Machines expand when warm, affecting precision

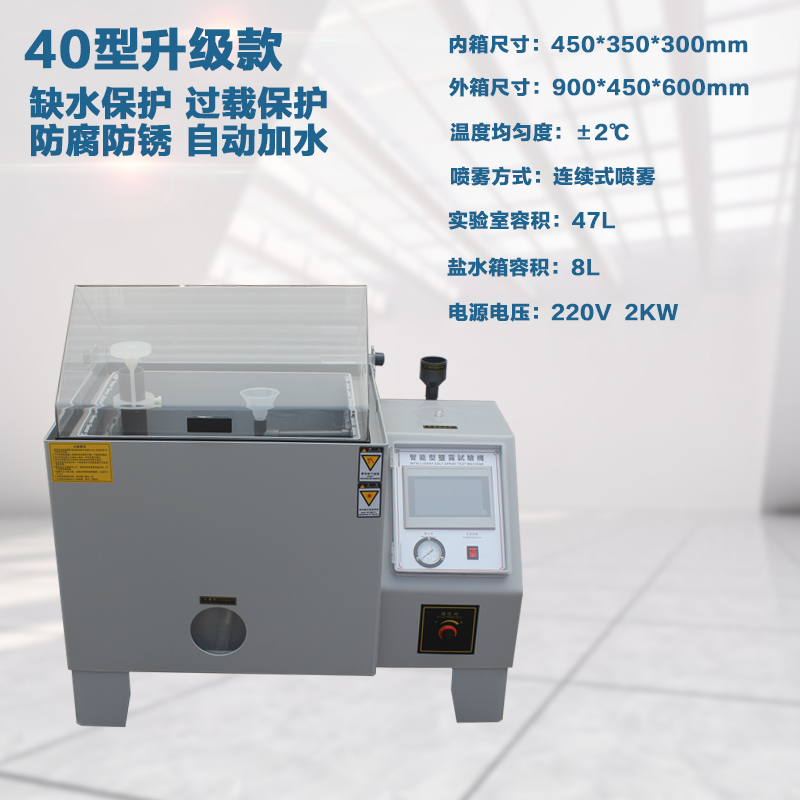

Testing & Quality Control Costs (2026 Data)

| Test Method | Cost per Part | Accuracy | Time per Part |

|---|---|---|---|

| Visual Inspection | $0.50–$2.00 | ±0.1mm | 1–2 min |

| CMM Measurement | $5–$20 | ±0.001mm | 5–15 min |

| Surface Roughness Test | $2–$8 | Ra 0.01μm | 2–5 min |

| Salt Spray Test | $10–$30 | Corrosion resistance | 24–72 hours |

Disclaimer: These are average costs based on 2026 industry data. Actual costs may vary by supplier and location.

2026 Sustainability Trends: Green CNC = Lower Costs?

Here’s a shocker: Sustainable CNC machining isn’t just good for the planet – it can save you money!

In 2026, more customers are asking for carbon footprint data, and smart shops are turning this into a competitive advantage.

Green Practices That Actually Reduce Costs

Dry Cutting / MQL

Cost savings: 15–30% on coolant costs

Minimum Quantity Lubrication uses 95% less coolant than flood cooling

Material Recycling

Cost savings: $500–$5,000 per month in scrap value

Properly sorted aluminum chips can fetch $0.50–$1.00 per pound

Energy-Efficient Machines

Cost savings: 20–40% on electricity bills

Newer machines use regenerative braking and smart idle modes

2026 Sustainability Requirements

- ISO 14001 certification for most OEMs

- Carbon footprint reporting per part

- Recycled content minimums (10–30%)

- Zero hazardous waste to landfill

Dude, this isn’t optional anymore. Get on board or lose business!

Carbon Footprint Data (2026 Average)

| Material | kg CO2 per kg material | kg CO2 per machining hour | Total per 1kg part |

|---|---|---|---|

| Aluminum 6061 | 12.5 | 0.8 | 13.3 |

| Stainless Steel 304 | 2.9 | 1.2 | 4.1 |

| Titanium Grade 5 | 40.0 | 2.0 | 42.0 |

| Recycled Aluminum | 0.5 | 0.8 | 1.3 |

Disclaimer: These are average values based on 2026 industry data. Actual emissions may vary by production method.

2026 CNC Machining Standards You Need to Know

Let’s get real: If you don’t know these standards, you’re gonna get burned.

I’ve seen parts rejected because they didn’t meet ISO 2768 tolerances.

Here’s what you need for 2026.

Key ISO Standards

ISO 2768

General tolerances for linear and angular dimensions

Classes: Fine (f), Medium (m), Coarse (c), Very Coarse (v)

ISO 230-4

Circular tests for CNC machine tools

Tests contouring performance of simultaneous axis movements

ISO 13041

Test conditions for turning centers

Establishes tolerances for turning machines

Industry-Specific Standards

Aerospace: AS9100

Tolerances down to ±0.005mm

Requires full traceability and documentation

Medical: ISO 13485

Biocompatible materials required

Strict cleanliness and sterilization standards

Automotive: IATF 16949

Process capability (Cpk > 1.33)

Continuous improvement requirements

Pro Tip from the Shop Floor

Dude, always specify the tolerance class! If you just say “precision machining”,

shops will charge you for the tightest tolerances by default.

Use ISO 2768-m for most applications – it’s the sweet spot.

2026 Real-World Case Studies

Drone Bracket Project

Material: Aluminum 6061

Batch: 50 units

Complexity: Medium (3 operations)

Finish: Anodized

Actual Cost: $85 per unit

Lessons Learned: Combining operations reduced setup time by 40%

Medical Implant

Material: Titanium Grade 5

Batch: 5 units

Complexity: Very Complex (5-axis)

Finish: Polished + Sterilized

Actual Cost: $2,200 per unit

Lessons Learned: Tight tolerances (±0.005mm) doubled machining time

Automotive Sensor Housing

Material: PEEK Plastic

Batch: 500 units

Complexity: Medium (4 operations)

Finish: As-machined

Actual Cost: $45 per unit

Lessons Learned: Large batch size reduced unit cost by 60% vs small batch

2026 Cost Reduction Hacks That Actually Work

Design for Manufacturing (DFM) Tips

- Simplify geometry: Remove unnecessary features. Every extra hole or slot adds time.

- Use standard tolerances: ISO 2768-m is good enough for 90% of applications.

- Avoid deep cavities: They require special tools and slow machining.

- Combine features: Can that hole and slot be made in one operation?

- Use common materials: Aluminum is cheaper and faster to machine than exotic metals.

Supply Chain Strategies

- Consolidate orders: Batch similar parts to reduce setup time.

- Long-term partnerships: Annual contracts get 10-20% discounts.

- Local vs offshore: Balance cost with lead time and quality control.

- Material substitution: Can you use aluminum instead of titanium?

- Design standardization: Use common features across multiple products.

The #1 Cost Reduction Tip for 2026

Get a DFM review BEFORE you start production!

A good DFM review can reduce costs by 30-50% and eliminate 90% of potential defects.

I’ve saved clients $100k+ on single projects just by simplifying designs.

2026 CNC Machining FAQ

How accurate is CNC machining in 2026?

Modern CNC machines can hold tolerances down to ±0.002mm (2 microns) with proper calibration.

Most shops work to ±0.01mm as standard, and ±0.005mm for precision applications.

What’s the lead time for custom CNC parts?

Small batches (1-10 units): 3-7 days

Medium batches (10-100 units): 7-14 days

Large batches (100+ units): 14-30 days

Pro tip: Emergency rush orders cost 20-50% more but can be done in 24-48 hours.

How do I choose between 3-axis, 4-axis, and 5-axis machining?

3-axis: Simple 2D and basic 3D parts – cheapest option

4-axis: Parts that need rotation around one axis – good for cylindrical features

5-axis: Complex 3D parts with features on multiple sides – most expensive but most capable

Dude, don’t overbuy! 90% of parts can be done on 3-axis machines.

What’s the most cost-effective material for CNC machining?

Aluminum 6061 is the best all-around choice for most applications.

It’s cheap, easy to machine, and has good strength-to-weight ratio.

If you need corrosion resistance, consider stainless steel 304, but it’s 2-3x more expensive to machine.

How much does CNC programming cost?

Programming costs are usually included in the machining quote, but expect to pay $50-150 per hour for complex parts.

Simple parts can be programmed in 1-2 hours, while complex 5-axis parts may take 10-20 hours.

What’s the difference between CNC machining and 3D printing?

CNC: Subtractive manufacturing – removes material from a solid block. Better for metals, tighter tolerances, higher strength.

3D Printing: Additive manufacturing – builds parts layer by layer. Better for complex geometries, small batches, plastics.

Rule of thumb: Use CNC for metals and functional parts, 3D printing for prototypes and complex plastic parts.

Ready to Get a 2026 CNC Machining Quote?

Send us your CAD files and we’ll provide a detailed quote with DFM analysis within 24 hours.

All quotes include 2026 sustainability metrics and defect risk assessment.

© 2026 CNC Machining Cost Guide | Updated January 2026 | All data based on 2026 industry averages

Disclaimer: This guide is for informational purposes only. Actual costs may vary by supplier, location, and specific project requirements.