Answer

The cost to CNC a small part typically ranges from $5 to $200, depending on materials, complexity, precision, and batch size. Simple aluminum parts (e.g., bolts, spacers) in small batches (1–10 units) cost $5–$30 per piece, while ABS plastic parts can be as low as $3–$15 per piece. Titanium small parts with complex curves or high precision (±0.05mm) for medical devices may cost $100–$200 per piece. Hourly rates generally fall between $50–$150, with 5-axis machining for intricate structures costing more ($100–$200/hour). Small batches incur 30%–50% higher costs due to frequent setup adjustments, and surface treatments (e.g., gold plating, black oxide) add $5–$50 per piece.

Technical Analysis: Key Factors Influencing Small Part CNC Costs and Optimization Strategies

1. Material Selection: The Foundation of Cost-Performance Balance

- Metals:

- Aluminum (e.g., 6061) is low-cost ($2.5–$3.5/kg) and easy to machine, suitable for prototypes and general components, with small parts often costing <$20 per piece.

- Titanium (e.g., TC4) offers high strength but is difficult to machine (rapid tool wear), costing $35–$55/kg—5–8 times more than aluminum for similar parts.

- Stainless steel (316L) is corrosion-resistant but has high cutting resistance, increasing machining costs by 20%–30% compared to aluminum.

- Non-Metals:

- Plastics like ABS and nylon cost only $3–$6/kg, ideal for lightweight small parts (e.g., gears, clips) with unit costs often <$10.

- High-performance plastics (e.g., PEEK) resist high temperatures but cost >$100/kg, driving medical small part costs above $50 per piece.

- Cost Optimization: Substitute aluminum for steel, use standard stock to minimize waste, and secure 10%–20% material discounts through bulk purchasing.

2. Geometric Complexity and Precision: Core Drivers of Machining Time

- Structural Features:

- Simple geometries (e.g., cylinders, plates): Processed via 3-axis milling or turning in <0.5 hours, costing $10–$30 per piece.

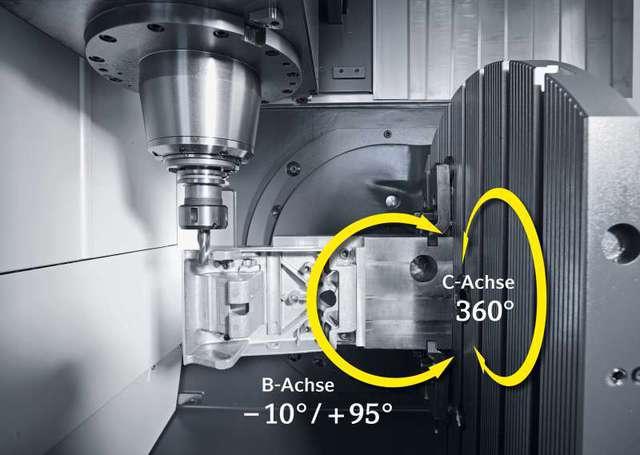

- Complex features (deep slots, thin walls, undercuts): Require multi-axis machining or multiple setups. For example, a 0.5mm thin-walled part needs 5-axis processing, increasing time by 2–3x and costs to $50–$100 per piece.

- Tolerance & Surface Roughness:

- Standard precision (±0.1mm): Achievable with general machines, low cost; high precision (±0.01mm) requires precision grinders or slow wire EDM, making medical needle fittings 40% costlier than standard parts.

- Mirror surfaces (Ra<0.8μm): Require polishing/grinding, adding $10–$30 per piece.

- Process Examples:

- Turning a 5mm aluminum pin: 0.1 hours/unit, cost $8–$15 (including material).

- Milling a stainless steel bracket with 0.2mm slots: 1.5 hours/unit, cost $80–$120.

3. Batch Size: The Core Logic of Scale Cost Reduction

- Small Batches (1–10 units):

- High setup time (1–2 hours for tool changes and fixture calibration) adds $30–$50 in fixed costs per piece, making total costs 30%–50% higher than medium batches.

- Case: 10 aluminum parts (0.5 hours/unit) cost $25–$35 per piece (including $20 setup fees).

- Medium Batches (50–500 units):

- Spreading setup costs reduces unit machining time (e.g., batch clamping minimizes part changes), cutting costs by 20%–40%.

- Case: 50 parts lower unit cost to $15–$25, saving ~$100 vs. small batches.

- Large Batches (1,000+ units):

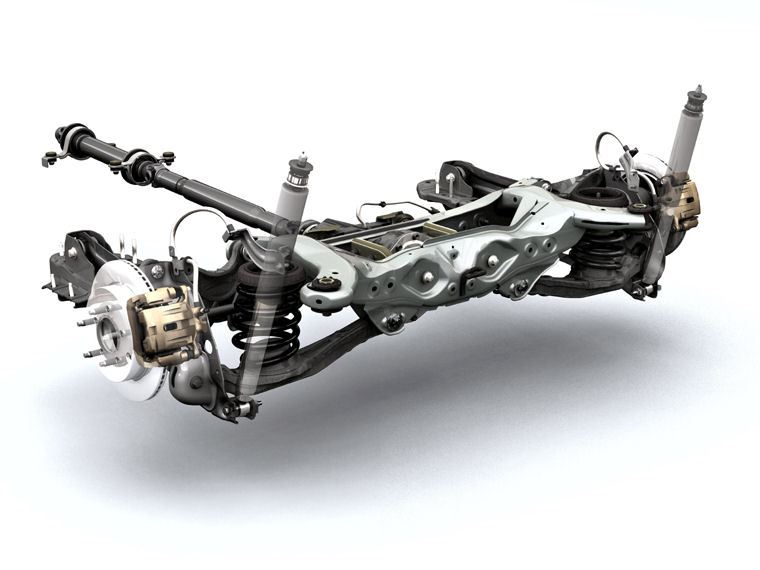

- Dedicated tooling and automated loading boost efficiency by 50%, driving costs as low as $5–$10 per piece for automotive small parts.

4. Surface Finishing: The superimpose Effect of Function and Cost

- Protective Treatments:

- Anodizing (aluminum): $0.5–$2 per piece (batch pricing for small parts), enhances corrosion resistance.

- Black oxide (steel): $1–$5 per piece, low-cost but limited rust protection.

- Decorative & Functional Treatments:

- Nickel/chrome plating: $3–$10 per piece, improves wear resistance and aesthetics; gold plating (medical) costs $20–$50 per piece due to material expense.

- PVD coatings (e.g., TiN): $5–$15 per piece, increase hardness for precision parts.

- Cost Control: Choose cost-effective solutions, such as spray painting ($2–$5/unit) over plating for indoor parts, or zinc-nickel plating ($8–$12/unit) instead of stainless steel for outdoor use.

5. Design Optimization: Reducing Machining Difficulty at the Source

- Simplify Features:

- Avoid blind holes with depth-to-diameter ratios >5 (e.g., 1mm diameter × 6mm depth), which risk tool breakage and increase costs by 30%; converting to through-holes saves 20% machining time.

- Eliminate unnecessary chamfers and fillets (e.g., <0.5mm fillets require special tools, increasing tool change frequency).

- Standardize Design:

- Use standard threads (e.g., M2, M3) and hole diameters (φ3, φ5) to avoid custom tools (cost +$50–$100 per tool).

- Use parametric design software (e.g., SolidWorks) to quickly modify dimensions for standard stock, reducing waste.

- DFM (Design for Manufacturability) Tips:

- Maintain wall thickness ≥0.8mm (aluminum)/1.2mm (stainless steel) to prevent machining deformation.

- Ensure slot widths ≥ tool diameters (e.g., 3mm slot with 3mm end mill) to avoid multiple passes.

6. Equipment & Process Selection: Balancing Efficiency and Precision

- Equipment Types:

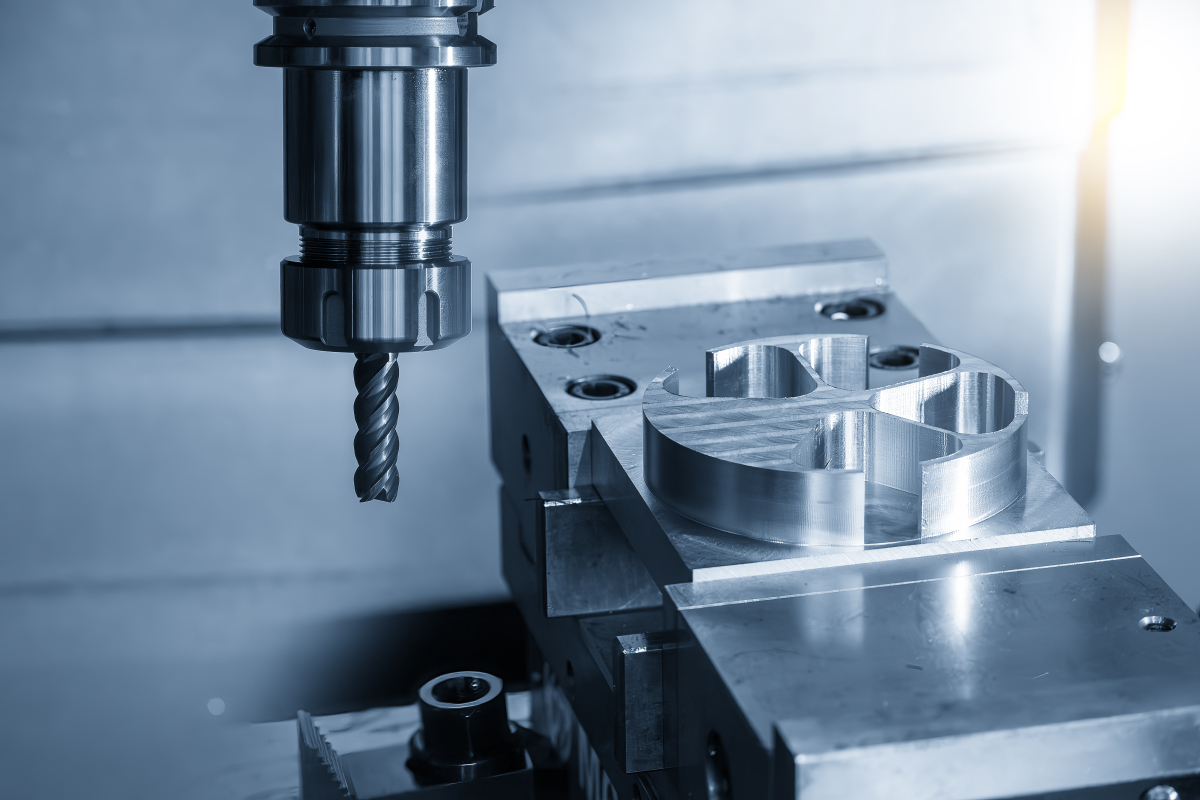

- 3-axis CNC mills: Suit planar and simple contour machining, with hourly rates $50–$80 for basic parts.

- 5-axis machining centers: Complete multi-sided processing in one setup for complex surfaces (e.g., impellers, molds), at $100–$200/hour, but reduce setup costs.

- Cutting Processes:

- High-speed milling (HSM): Ideal for aluminum parts, 30% faster than conventional milling with better surface quality.

- Electrical discharge machining (EDM): Suits hard alloys (e.g., tungsten steel punches) but is slow ($80–$120/hour) and costly.

- Automation Solutions:

- Robotic loading (initial investment $50,000+) is suitable for large batches, reducing labor costs by 40%.

7. Supply Chain & Regional Factors: Balancing Cost and Responsiveness

- Overseas Machining (e.g., China):

- Quotes are 30%–60% lower than Europe/North America, with small part costs as low as $3–$15 per piece, but factor in shipping ($5–$20/batch) and lead times (1–4 weeks).

- Case: 100 aluminum parts cost ~$800 from China vs. $1,200–$1,500 in the West.

- Local Machining (Emergency Needs):

- Ideal for rapid prototyping (3–7-day delivery) but costs 20%–50% more, with small batches possibly incurring $50–$100 expedite fees.

Cost Estimation Case Comparisons

| Small Part Type | Material | Complexity | Batch | Surface Finishing | Unit Cost Range |

|---|---|---|---|---|---|

| Aluminum Spacer | 6061 | Circular Plate | 10 units | Natural Anodizing | $8–$15 |

| Titanium Medical Screw | TC4 | Thread + Head | 5 units | Polishing + Sterilization | $120–$180 |

| ABS Plastic Gear | ABS | Involute Teeth | 50 units | Natural Finish | $5–$10 |

| Stainless Steel Micro Bracket | 316L | 0.3mm Hole Array | 20 units | Electropolishing | $40–$60 |

| Brass Electrical Connector | H62 Brass | Multi-Pin Structure | 100 units | Gold Plating (0.1μm) | $15–$25 |

Cost Reduction Strategies

- Consolidate Operations: Process multi-step parts (e.g., milling + drilling) on a single complex machine (e.g., mill-turn center) to reduce setup frequency (each setup costs $10–$30).

- Optimize Programming: Use CAM software for efficient toolpaths (e.g., helical ramping vs. vertical plunging), reducing air cutting time by 15%–20%.

- Share Fixtures: Negotiate with suppliers to use standard fixtures (e.g., vises, magnetic tables) to avoid custom fixtures (cost $200–$500 per set).

- Scrap Recycling: Recycle waste from precious materials (e.g., brass, titanium) to offset 5%–10% of material costs.

CNC machining cost control for small parts is fundamentally a systematic optimization of “materials-processes-batch-design”. By precisely matching requirements to cost factors, maximum cost-performance can be achieved while ensuring functionality.