Tool life is the total cutting time or number of good parts a tool can produce before it must be replaced or reground. Accurate prediction prevents unplanned downtime and controls cost.

1. Core Definitions

Tool life (T): minutes of actual cutting until a defined wear limit is reached.

Tool durability: cutting time between two successive regrinds.

Total tool life: durability × (number of regrinds + 1).

2. Classic Calculation Models

A. Taylor’s Equation (VTm = C)

V = cutting speed (m/min)

T = tool life (min)

m, C = material & tool constants from supplier tables

B. Practical Shop-Floor Formulas

|

Method

|

Formula

|

Units

|

|

By cutting time

|

N = 19100·V·f / (D·h)

|

parts

|

|

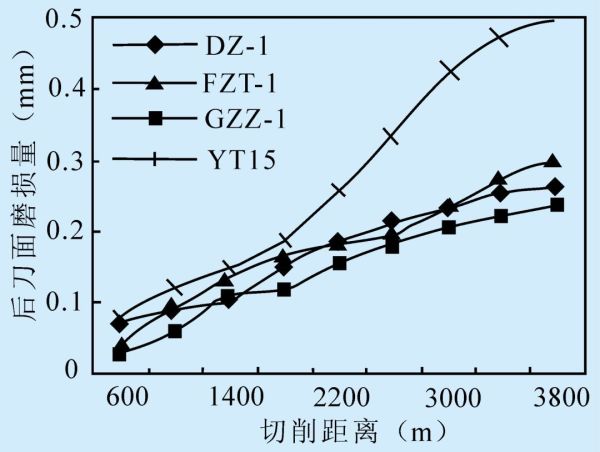

By cutting distance

|

N = 318300·L·f / (D·h)

|

parts

|

V = m/min, f = mm/rev, D = mm, h = mm, L = km

3. Data-Driven & AI Approaches

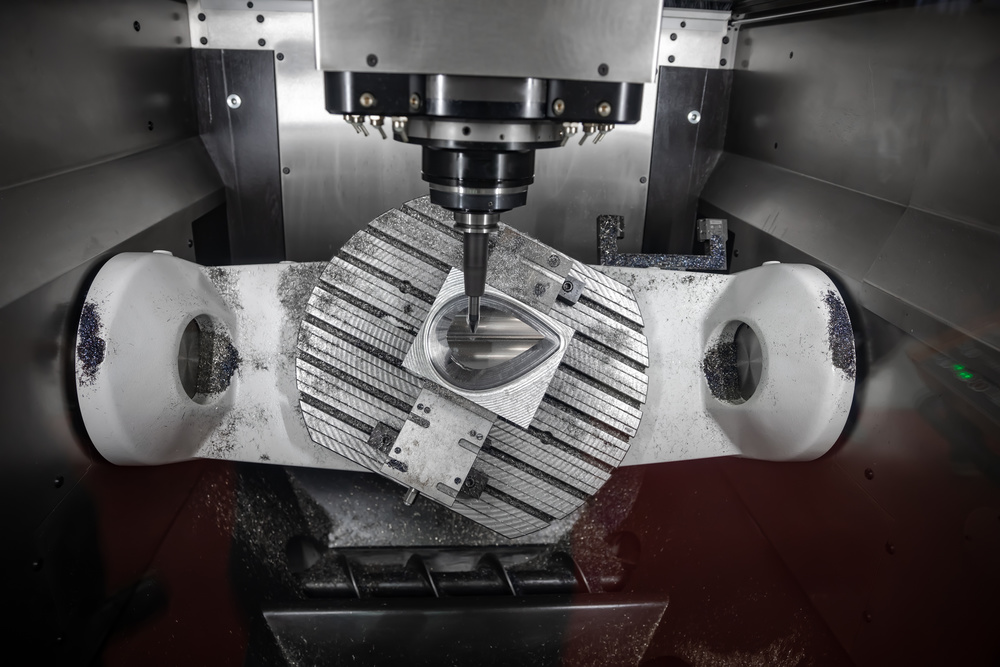

Modern CNC controllers collect spindle-load, vibration and temperature data in real time. Edge AI models (e.g., AT-LSTM networks) convert these signals into remaining-useful-life predictions with ±5 % accuracy.

4. Step-by-Step Planning Workflow

Collect baseline data: record tool, material, speed, feed and actual failure time.

Choose a model: start with Taylor for quick estimates, then refine with shop-floor formulas.

Set a safety factor: 75 % of calculated life is common industrial practice.

Implement condition monitoring: add spindle-load sensors and AI prediction for dynamic updates.

Automate alerts: program the CNC to lock the spindle and prompt change when the preset count or predicted life is reached.

5. Replacement Decision Matrix

|

Indicator

|

Action

|

|

Flank wear ≥ 0.2 mm

|

Immediate change

|

|

Surface roughness ↑ 20 %

|

Schedule change

|

|

Spindle load ↑ 15 %

|

AI flag → change soon

|

Disclaimer

All experimental data presented in this paper are derived from controlled production environments and standardized test procedures. However, due to differences in equipment models, material batches, and on-site operating conditions, readers are advised to verify and adjust technical parameters according to their specific application scenarios before practical implementation.