In the fields of large – scale equipment manufacturing such as automotive, aerospace, and home appliances, large – scale injection – molded parts, with their characteristics of integral molding and complex structures, have become crucial for enhancing product performance and production efficiency. The large – scale component injection – molding service achieves the leap from “extensive processing” to “precision intelligent manufacturing” through innovative mold technologies, intelligent molding processes, and full – process quality control.

I. Why Can’t Traditional Injection Molding Meet the Processing Requirements of Large – scale Components?

Q&A: What are the core advantages of the large – scale component injection – molding service?

Traditional injection – molding processing has three core pain points when dealing with large – scale components (size ≥ 500mm, weight ≥ 5kg):

Loss of dimensional accuracy control: Large – scale molds are prone to deformation (displacement deviation ±1 – 2mm) during the mold – opening and – closing process. Uneven cooling and shrinkage of the plastic melt result in a warpage deformation rate of the components exceeding 3%, and the key – dimension tolerance often reaching ±0.5mm, which cannot meet the requirements of precise assembly.

Frequent molding defects: The long melt flow path (over 2m) and long filling time make problems such as weld lines, air entrapment, and sink marks likely to occur. Under traditional processes, the defect rate is as high as 15% – 20%, and the qualification rate of large – scale automotive bumpers is even less than 70%.

Low production efficiency: The clamping force of conventional injection – molding machines is insufficient (< 2000T), and the mold cooling time is long (single – piece cycle > 3 minutes), making it difficult to achieve high – efficiency mass production and resulting in a 40% – 60% increase in costs.

However, the large – scale component injection – molding service takes “high precision, high efficiency, and high stability” as the core:

Full – process precise control:

Dimensional accuracy assurance: Use a high – precision five – axis machining center to manufacture molds (accuracy ±0.02mm), combined with intelligent mold – temperature control and dynamic packing technology, to control the component dimensional tolerance within ±0.15mm and reduce the warpage deformation rate to less than 0.8%.

Defect prevention system: Optimize the gate layout and runner design through CAE mold – flow analysis, and cooperate with vacuum – assisted molding and sequential valve control. The strength of weld lines is increased by 50%, and defects such as air entrapment and sink marks are reduced by 90%.

Data – driven efficient production: Use an intelligent injection – molding system to optimize process parameters in real – time, shortening the single – piece molding cycle by 25% – 35% and increasing the overall equipment effectiveness (OEE) to 85%, helping enterprises deliver orders quickly.

II. How Does the Core Process of Large – scale Component Injection Molding Achieve Breakthroughs?

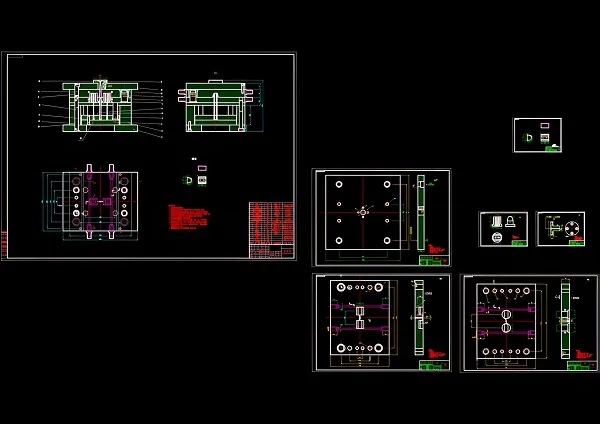

Innovative technologies for extra – large molds

Modular spliced molds: For extra – large components (such as body panels), adopt a segmented mold design. Splice through high – precision dowel pins (fit tolerance ±0.01mm) and high – strength bolts, reducing the weight of a single mold by 30%, lowering processing difficulty and costs. At the same time, it is convenient for mold maintenance and local replacement.

Conformal cooling molds: Use 3D – printing technology to manufacture the mold cooling water channels, which are designed to fit the complex surfaces of the components. The mold temperature uniformity is increased by 60%, the cooling time is shortened by 40%, and the single – piece molding cycle is reduced from 3 minutes to 1.8 minutes.

High – strength mold materials: Select modified H13 steel (hardness HRC48 – 52), and the surface is treated with TD coating (thickness 3 – 5μm). The wear resistance is increased by 3 times, and the mold life is extended to more than 500,000 times, suitable for long – term mass – production requirements.

Intelligent injection – molding processes

Upgrade of large – scale injection – molding equipment: Equip with extra – large injection – molding machines (clamping force 5000 – 12000T, injection volume 50 – 200kg), and use a servo – hydraulic system (response time < 0.1s) to ensure high – speed, high – pressure, and high – precision injection, meeting the rapid filling requirements of large – scale components.

Multi – stage injection control: Real – time monitor the melt flow through pressure sensors (accuracy ±0.5MPa) and displacement sensors (accuracy ±0.05mm), and control the injection speed (0.1 – 1m/s) and pressure (80 – 180MPa) in stages to avoid problems such as jetting and short – shot. The filling success rate is over 99%.

Vacuum – assisted molding: Evacuate the mold cavity to – 95kPa to eliminate the risk of air entrapment, reduce bubbles and surface air streaks. At the same time, the melt flow resistance is reduced by 30%, improving the molding ability of thin – wall (2 – 3mm) large – scale components.

Digital production control system

Mold – flow analysis pre – research: Use Moldflow software to simulate the flow state of the melt in the large – scale mold, optimize the number of gates (usually 3 – 8), the runner diameter (12 – 25mm), and the cooling – loop layout, and predict and solve more than 85% of the molding defects in advance.

Intelligent process control: Real – time collect more than 60 parameters such as mold temperature (accuracy ±1℃), melt pressure, and screw speed. The AI algorithm automatically adjusts the process curve to compensate for material batch differences and environmental temperature changes, increasing the qualified rate from 75% to 93%.

Digital – twin monitoring: Create a digital – twin model for each set of large – scale molds, simulate the production process in real – time, predict the trends of mold wear and component deformation, and carry out maintenance and process optimization in advance, reducing unplanned downtime by 40%.

III. Quality Control: Stringent Verification throughout the Chain from Mold to Finished Product

Multi – dimensional performance testing system

Dimensional inspection: Use a laser tracker (accuracy ±0.05mm) and an articulated arm measuring machine to detect the overall dimensions and geometric tolerances (flatness ≤ 0.2mm) of large – scale components, and generate a three – dimensional deviation report.

Mechanical properties: Use a universal material testing machine to detect tensile strength and flexural modulus. For automotive components, conduct collision simulation tests to ensure compliance with safety standards.

Appearance inspection: The AI vision inspection system (resolution 20 million pixels) completes the surface inspection in 0.8 seconds, identifying 0.1mm – level scratches and depressions below 1mm², with a missed – detection rate of less than 0.003%.

Coordinate measuring machine inspection: Precision – measure the key dimensions of the mold (such as cavity depth, slider fit clearance) (accuracy ±0.01mm) to ensure the mold manufacturing accuracy.

Flaw detection: Use ultrasonic flaw detection (UT) and magnetic particle flaw detection (MT) to detect internal cracks and surface defects of the mold, ensuring the mold strength and reliability.

Mold – level inspection:

Product – level testing:

Intelligent defect – prevention technologies

First – piece twelve – inspection system: The engineering team strictly inspects 45 indicators of the first – piece product, such as mold status, material batch, and process parameters, intercepting potential defects.

Real – time process monitoring: Through pressure sensors and temperature sensors embedded in the mold, real – time monitor the melt filling and cooling processes. In case of abnormalities, automatically alarm and trigger shutdown to prevent batch non – conformities.

IV. How to Balance Efficiency and Cost in the Production of Large – scale Components?

Q&A: Does large – scale injection molding mean high cost and low efficiency?

Through three innovative models, large – scale component injection molding achieves a 30% – 40% cost reduction and a 50% increase in production efficiency:

Mold optimization strategy: Adopt modular mold design and quick – mold – change technology (mold – change time < 20 minutes), reducing the mold development cost by 35% and meeting the production requirements of multi – variety and small – batch production at the same time.

Energy management system: Intelligently control the servo – motor power of the injection – molding machine and the cooling water temperature of the mold. Combined with waste – heat recovery technology, energy consumption is reduced by 25%, and the unit production cost is decreased by 18%.

Shared manufacturing platform: Integrate the large – scale component order demands of multiple customers, schedule production centrally, and share the resources of extra – large injection – molding equipment. The equipment utilization rate is increased from 50% to 80%, further reducing costs.

V. Core Considerations for Choosing Large – scale Component Injection – Molding Services

Equipment and technical strength: The supplier should have large – scale injection – molding machines above 5000T, high – precision five – axis processing equipment, and core technologies such as modular mold design and vacuum – assisted molding.

Digitalization ability: Have mold – flow analysis, intelligent production management systems, and digital – twin technologies to achieve full – process data – driven and ensure efficient and controllable production.

Quality – assurance system: Provide ISO 9001 certification, third – party test reports, and a complete after – sales quality – traceability service to ensure that products meet industry standards.

Conclusion

The large – scale component injection – molding service, driven by innovative technologies and intelligent management, overcomes the technical bottlenecks of traditional injection – molding processing and provides enterprises with high – precision and high – efficiency large – scale injection – molding solutions. In the trend of the development of the manufacturing industry towards intelligence and integration, the large – scale component injection – molding service with “advanced mold technologies + intelligent molding processes + full – chain quality control” is becoming the key support for enhancing product competitiveness in fields such as automotive and aerospace. From integrated automotive body components to large – scale home – appliance shells, the large – scale component injection – molding service will continue to help enterprises achieve efficient production and innovative development with excellent precision and efficiency.

(Contact us immediately to obtain a customized large – scale component injection – molding solution and a free mold – flow analysis service)