Injection molding is one of the most widely used plastic processing methods in modern manufacturing. From everyday plastic cups to complex automotive components, many of the plastic products around us are manufactured through this process.

Basic Principles

The core idea of injection molding is actually quite simple: solid plastic materials are heated and melted into a liquid state, then injected into a specially shaped mold under high pressure. After the plastic cools and solidifies, a product that exactly matches the mold’s shape is obtained.

This process is somewhat like making ice cubes – pour water into an ice tray mold, put it in the refrigerator to cool, then take it out to get ice cubes of fixed shapes. The difference is that injection molding deals with plastic and requires higher temperatures and pressures.

**

Main Equipment

Injection Molding Machine

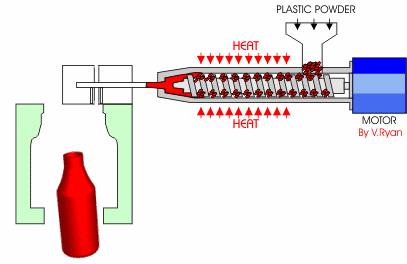

The injection molding machine is the core equipment for injection molding, mainly composed of three parts:

Injection System

This part is responsible for heating and melting plastic materials and injecting them into the mold. It includes a hopper (for storing plastic pellets), a heating barrel (for melting plastic), and a screw (for pushing molten plastic).

Clamping System

Used to fix the mold and keep it closed during the injection process. This part needs to provide sufficient clamping force to prevent the mold from opening during high-pressure injection.

Control System

Includes temperature control, pressure control, time control, etc., ensuring the entire molding process is carried out precisely according to set parameters.

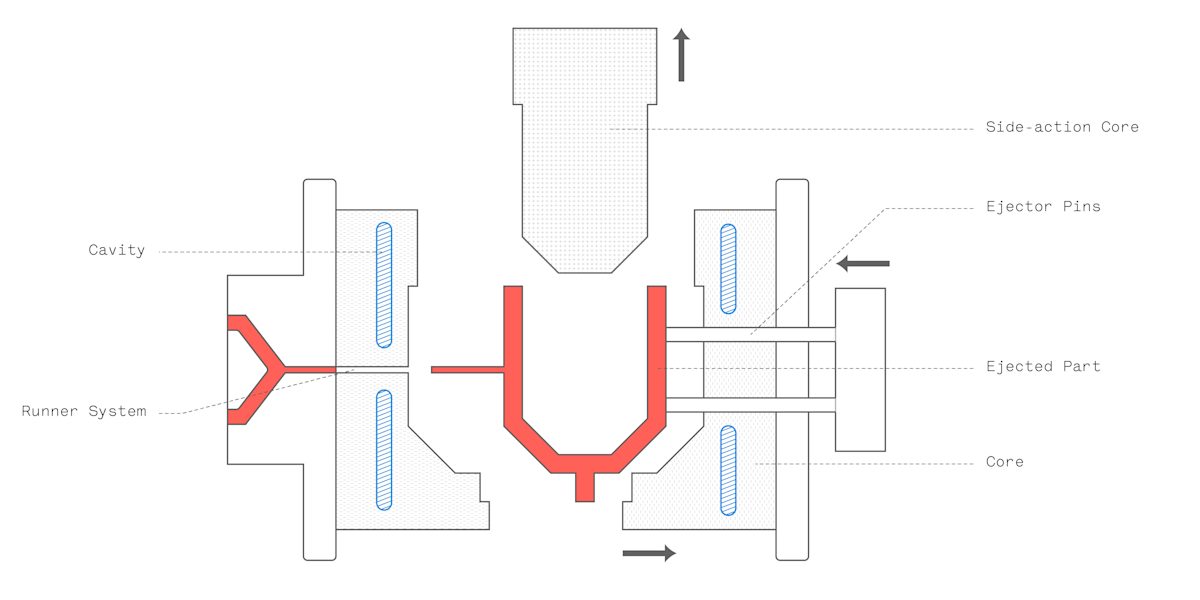

Injection Mold

The mold is a key component that determines the final product shape, usually consisting of two parts: moving mold and fixed mold. The cavity inside the mold is called the mold cavity. After molten plastic is injected into the cavity and cooled, it takes shape.

The manufacturing precision of the mold directly affects product quality, usually made of steel or aluminum with precision machining. Complex molds also include cooling systems, ejection mechanisms, gating systems, etc.

Process Flow

Material Preparation

The raw materials used in injection molding are usually plastic pellets or powder. Different types of plastics have different characteristics, so suitable materials need to be selected according to product requirements.

Some plastic materials need to be dried before use, especially hygroscopic materials like nylon, to remove moisture from the raw materials and avoid bubbles or silver streaks during the molding process.

Injection Molding Process

Plasticization Stage

Plastic pellets enter the heating barrel from the hopper and are heated to a molten state inside the barrel. The screw inside the barrel continuously rotates, pushing the plastic forward while uniformly melting it through shearing and heating.

Injection Stage

When molten plastic accumulates to a certain amount, the screw moves forward, injecting the molten plastic into the mold cavity through the nozzle at high pressure and speed. Injection pressure is usually between tens to hundreds of megapascals.

Packing Stage

After plastic is injected into the mold, the screw continues to maintain a certain pressure, supplementing the amount of plastic reduced due to cooling shrinkage into the mold to ensure stable product dimensions.

Cooling Stage

The cooling system inside the mold starts working, removing heat from the mold and plastic through circulating cooling water. The plastic gradually cools and solidifies inside the mold, forming a shape consistent with the mold cavity.

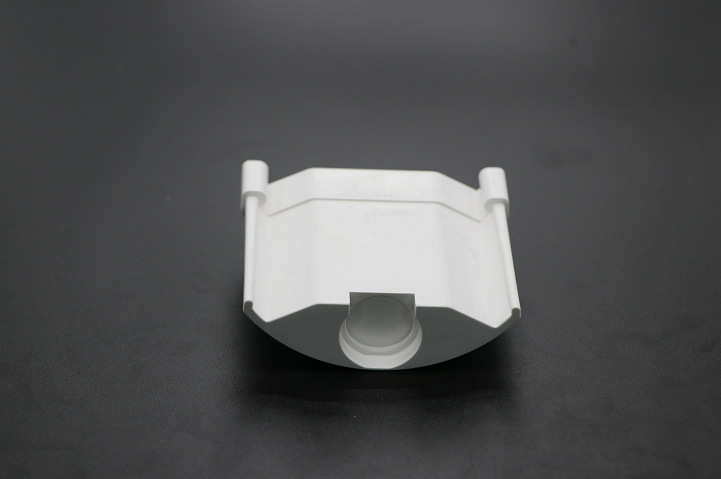

Ejection Stage

When the plastic is completely cooled and solidified, the mold opens, and the ejection mechanism pushes the molded plastic product out of the mold.

Common Materials

Thermoplastics

Polyethylene (PE)

Has good chemical stability and toughness, impact resistance, and low price. Commonly used for making packaging materials, containers, toys, etc.

Polypropylene (PP)

Low density, high strength, chemical corrosion resistance, and good heat resistance. Widely used in automotive parts, home appliance housings, medical devices and other fields.

Polyvinyl Chloride (PVC)

Adjustable hardness, chemical corrosion resistance, and good insulation. Used for pipes, wires and cables, building materials, etc.

Polystyrene (PS)

High transparency, easy processing, and low price. Commonly used for packaging materials, disposable tableware, toys, etc.

Acrylonitrile Butadiene Styrene (ABS)

Excellent comprehensive performance, high strength, good toughness, and easy processing. Widely used in home appliances, automobiles, electronics and other industries.

Polycarbonate (PC)

High transparency, good impact strength, and excellent heat resistance. Used for making optical discs, safety glass, electronic and electrical housings, etc.

Thermosetting Plastics

Thermosetting plastics undergo chemical reactions during the molding process, forming irreversible cross-linked structures. Common ones include phenolic plastics, epoxy resins, etc., mainly used for making electrical insulation parts, automotive brake pads, etc.

Application Fields

Daily Necessities

From plastic tableware, toys, cosmetic packaging to home appliance housings, injection molding covers almost all kinds of plastic products in our lives. These products usually require good appearance, accurate dimensions, and reasonable cost.

Automotive Industry

Many parts on automobiles are made by injection molding, including instrument panels, door panels, bumpers, radiator grilles, etc. Automotive plastics require high strength, heat resistance, and weather resistance.

Electronics and Electrical Appliances

Mobile phone housings, computer keyboards, connectors, switches and other electronic and electrical products widely use injection molding processes. These products usually require high dimensional accuracy, good appearance quality, and some need to have conductive or insulating properties.

Medical Devices

Syringes, infusion sets, surgical instruments, medical equipment housings and other medical devices widely use injection molding. Medical plastics require non-toxicity, odorlessness, sterilization resistance, and usually use medical-grade materials.

Packaging Industry

Various plastic bottles, bottle caps, containers, films and other packaging materials are mainly produced through injection or blow molding. Packaging plastics require good sealing, transparency, and printing performance.

Process Characteristics

Advantages

High Production Efficiency

Injection molding can achieve automated continuous production. A production cycle usually takes only tens of seconds to several minutes, suitable for mass production.

High Product Precision

Injection molding can produce products with high dimensional accuracy and good surface quality, with tolerance levels reaching IT5-IT7.

Great Design Freedom

Molds can produce complex geometric shapes, including internal cavities, threads, ribs, etc., reducing subsequent processing procedures.

Wide Material Selection

Various plastic materials can be used to meet different performance requirements.

Disadvantages

Large Equipment Investment

The cost of injection molding machines and molds is relatively high, especially the manufacturing cost of complex molds is expensive.

Long Production Cycle

The entire process from product design to mold manufacturing to trial production takes a long time.

Not Suitable for Small Batch Production

Due to high equipment and mold costs, injection molding is usually suitable for mass production, and the unit cost is relatively high for small batch production.

Quality Control

Common Defects and Causes

Bubbles

Moisture or volatile substances in raw materials, poor mold venting, and excessive injection speed may cause bubbles in products.

Warpage and Deformation

Uneven cooling, improper mold temperature control, and unreasonable product design can cause product warpage and deformation.

Flash

Insufficient clamping force, insufficient mold manufacturing precision, and excessive injection pressure can cause flash on products.

Short Shot

Insufficient injection volume, insufficient injection pressure, poor mold venting, and poor material flowability can cause short shots in products.

Testing Methods

Dimensional Inspection

Using calipers, micrometers, projectors, coordinate measuring machines and other equipment to inspect product dimensional accuracy.

Appearance Inspection

Visually inspecting product surfaces for bubbles, scratches, flash and other defects.

Performance Testing

Conducting strength tests, impact tests, heat resistance tests, chemical resistance tests, etc. according to product requirements.

Safety Precautions

Equipment Safety

Injection molding machines are heavy machinery and equipment. Operators must strictly follow safety operating procedures. Operators should wear appropriate protective equipment, such as safety helmets, safety glasses, protective gloves, etc.

During equipment operation, it is strictly forbidden to put hands into the mold area or touch moving parts. When equipment malfunctions, it should be shut down immediately and the power cut off, with maintenance performed by professional personnel.

Material Safety

Some plastics may release harmful gases during heating, such as polyvinyl chloride releasing hydrogen chloride gas when heated. Therefore, injection molding workshops should maintain good ventilation, and install exhaust systems if necessary.

Operators should understand the safety characteristics of the materials used and avoid direct contact with harmful raw materials. Waste plastic scraps should be disposed of according to environmental protection requirements to avoid environmental pollution.

Mold Safety

Molds will wear during use and need regular inspection and maintenance. Special tools should be used when installing and disassembling molds to avoid mold collision or damage.

High-temperature molds should be handled carefully to prevent burns during operation. Mold surface temperatures are usually between tens to hundreds of degrees Celsius.

Technology Development

Precision Injection Molding

With the increasing precision requirements for products in electronics, medical and other industries, precision injection molding technology has developed rapidly. By precisely controlling temperature, pressure, speed and other parameters, high-precision molding with product dimensional tolerances at the micron level is achieved.

Gas-Assisted Injection Molding

High-pressure gas is injected into the plastic melt during the injection process, using gas pressure to push the plastic to fill the mold cavity. This technology can reduce product wall thickness, reduce weight, and shorten cooling time.

Two-Color Injection Molding

Using two or more injection units, different colors or different materials of plastic are injected into the mold simultaneously or sequentially, forming two-color or multi-color products in one molding process. This technology can simplify the production process and increase product added value.

Micro-Injection Molding

Injection molding technology specifically used for producing micro-sized products, with product weights usually between a few milligrams to a few grams. Mainly used in medical devices, electronic components, precision machinery and other fields.

Reaction Injection Molding

A molding method where two or more liquid raw materials are mixed in a mold and undergo chemical reactions to form solid products. Mainly used for producing polyurethane foam, epoxy resin and other products.

After decades of development, injection molding technology has become a mature and efficient manufacturing process. It has not only changed our lifestyle but also promoted the development of modern manufacturing. From simple daily necessities to complex high-tech products, injection molding plays an important role in various fields.

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.