You might know that injection molding can make plastic products, but did you know there are actually many different types of injection molding technologies?

Just like chefs use different cooking methods – steaming, boiling, frying, grilling – injection molding also has various techniques, each with its own characteristics and applications.

Conventional Injection Molding: The Basic Technology

Conventional injection molding is the most basic and commonly used injection technology.

The principle is simple: heat plastic pellets until melted, then inject them into a mold under high pressure, and remove the product after cooling.

This technology is suitable for manufacturing various daily necessities such as plastic tableware, toys, and home appliance housings. Its advantages are low cost, high efficiency, and suitability for mass production.

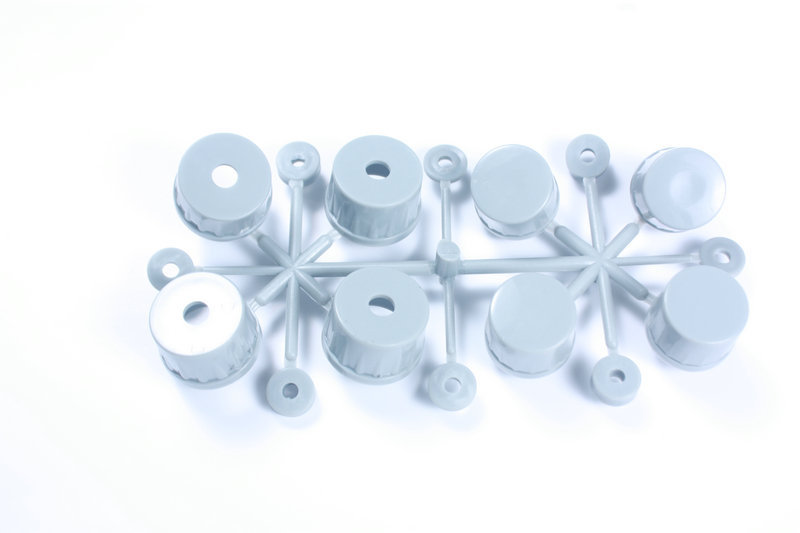

Two-color Injection Molding: Adding Layers to Products

Two-color injection molding can achieve combinations of two different colors or materials in the same product.

Think about your toothbrush: the handle is hard plastic, while the grip part is soft rubber. Products like this are likely made using two-color injection technology.

This technology requires special two-color injection molding machines and complex mold designs. The mold can rotate – first injecting one material, then rotating the mold to inject the second material.

The advantage of two-color injection is that it can make products more functional and aesthetically pleasing without the need for subsequent assembly.

Precision Injection Molding: Pursuing Ultimate Accuracy

Precision injection molding is specifically used for manufacturing products with extremely high precision requirements.

Products like mobile phone camera lenses and electronic connectors have very strict dimensional tolerance requirements, possibly only a few microns.

Precision injection requires high-precision injection molding machines, precision molds, and strict process control. The injection volume control accuracy can reach ±0.1%, and the mold temperature control accuracy can reach ±1°C.

Gas-assisted Injection Molding: Making Products Lighter

Gas-assisted injection molding involves injecting high-pressure nitrogen into the mold during or after plastic injection.

The gas forms a hollow structure inside the product, like a straw. This has several benefits:

- Reduces material usage and costs

- Eliminates surface sink marks

Common applications include automotive door handles, furniture armrests, and home appliance housings that need weight reduction.

Water-assisted Injection Molding: Faster and More Uniform

Water-assisted injection molding is similar to gas-assisted, but uses high-pressure water instead of gas.

Water has much better thermal conductivity than gas, so cooling is faster. At the same time, the incompressibility of water makes the hollow structure more uniform.

This technology is particularly suitable for manufacturing tubular products such as plastic pipes and automotive fuel pipes.

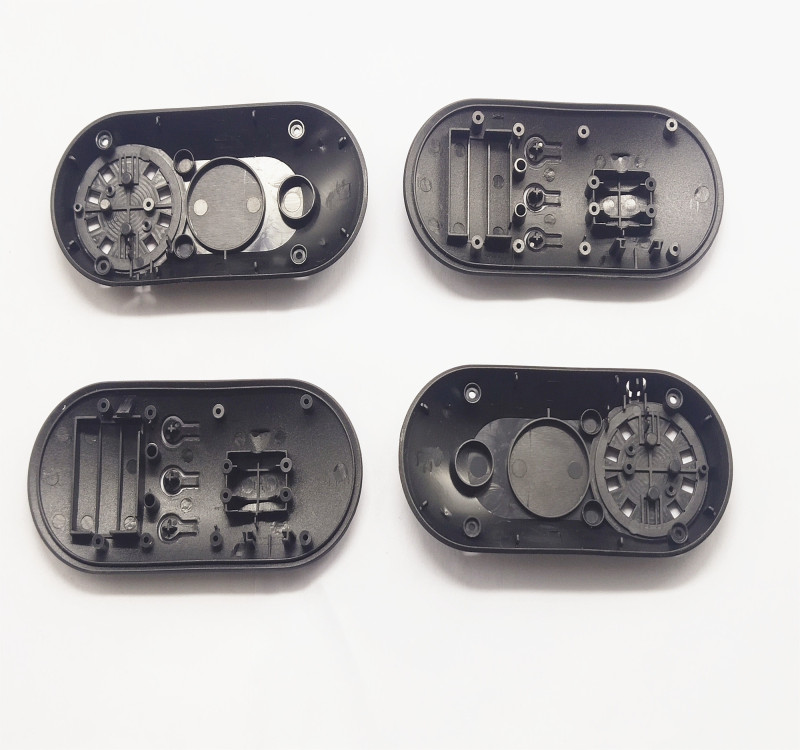

Insert Injection Molding: Strength in Combination

Insert injection molding involves placing inserts made of metal, ceramic, etc., into the mold first, then injecting plastic to encapsulate them.

Products made this way combine the advantages of different materials: plastic provides insulation and protection, while metal provides strength and conductivity.

Common applications include plastic parts with threads (with metal nuts embedded inside) and electronic connectors (with metal terminals embedded in plastic housings).

Microcellular Injection Molding: Internal Mysteries

Microcellular injection molding involves injecting supercritical fluids (carbon dioxide or nitrogen) into the molten plastic.

These fluids form countless tiny bubbles in the plastic, with diameters of only 10-100 microns.

The advantages of this technology are:

- Significantly reduced internal stress

- Reduced warpage and deformation

Hot Runner Injection Molding: Reducing Waste

Traditional injection molding produces gate waste that requires subsequent processing.

Hot runner injection molding maintains the plastic in a molten state in the runner system through heating. This eliminates gate waste and greatly improves material utilization.

This technology is suitable for mass production. Although the initial mold cost is higher, it is more economical in the long run.

Low-pressure Injection Molding: Gentle Care

Low-pressure injection molding uses relatively low injection pressure (usually 1-5MPa).

This technology is particularly suitable for encapsulating electronic components because low pressure will not damage sensitive electronic devices.

The materials used in low-pressure injection are usually hot melt adhesives, which have good sealing and protective properties, providing waterproof, dustproof, and shockproof effects.

High-gloss Injection Molding: Mirror-like Finish

High-gloss injection molding achieves a mirror-like surface finish on products through precise control of mold temperature.

The process is: first rapidly heat the mold above the glass transition temperature of the plastic, then inject the plastic, maintain the high temperature for a period of time, and finally cool rapidly.

Products made this way have extremely smooth surfaces without the need for subsequent painting, saving costs and being more environmentally friendly.

How to Choose the Right Technology

Choosing which injection technology to use mainly considers the following factors:

Product Requirements: Precision, appearance, strength, weight, etc.

Material Properties: Different materials are suitable for different processes

Production Volume: Mass production and small-batch production may require different technologies

Cost Budget: Different technologies have different equipment and mold costs

Delivery Time: Some technologies have longer development cycles

Technology Development Trends

With technological development, injection molding technology is constantly advancing:

Intelligentization: Using AI technology to automatically optimize process parameters

Green Environmental Protection: Developing more environmentally friendly materials and processes

Precision: Continuously improving product precision and quality

Compound: Combined application of different technologies

Personalization: Small-batch customized production technology

The diversified development of injection molding technology provides more possibilities for product design. From simple daily necessities to complex high-tech products, suitable injection technologies can be found for manufacturing.

Understanding these different injection technologies helps us better understand how plastic products around us are made, and also provides more ideas for product design and manufacturing.