I. Plastic Part Manufacturing: Injection Molding or 3D Printing?

Production Volume Determines Direction

Design Maturity Considerations

II. Customization Process Differences

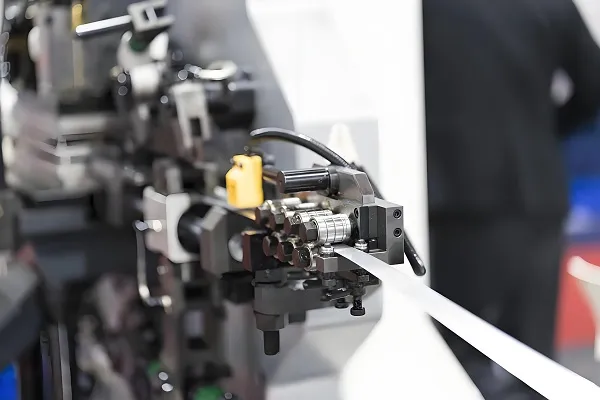

Injection Molding Customization Process

- Design & Engineering – CAD modeling and mold design

- Mold Fabrication – CNC machining of metal molds

- Tooling Validation – Test runs and adjustments

- Production – Mass manufacturing

- Quality Control – Inspection and packaging

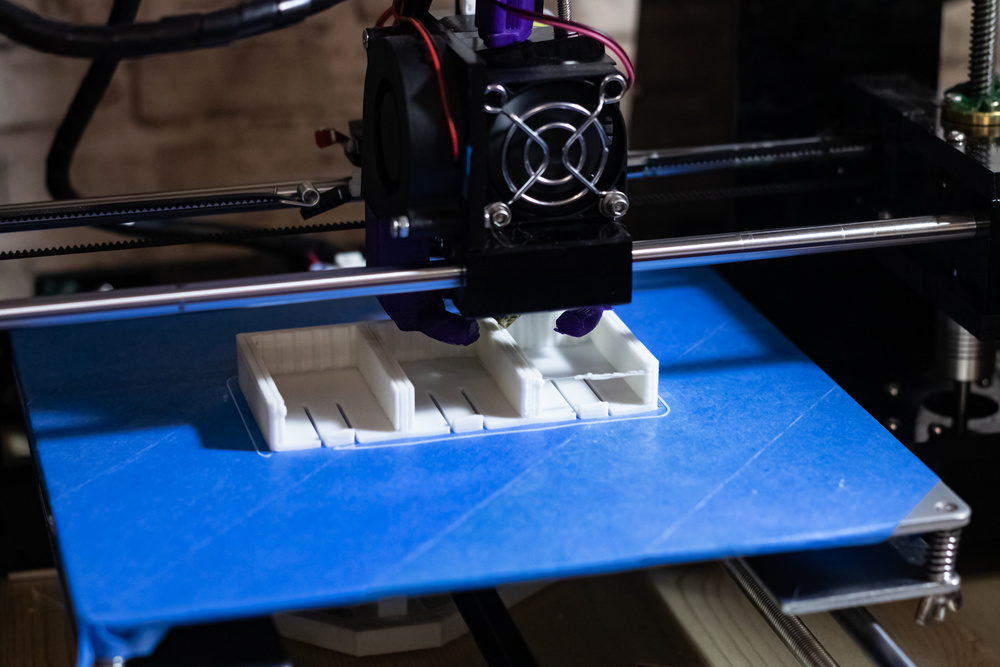

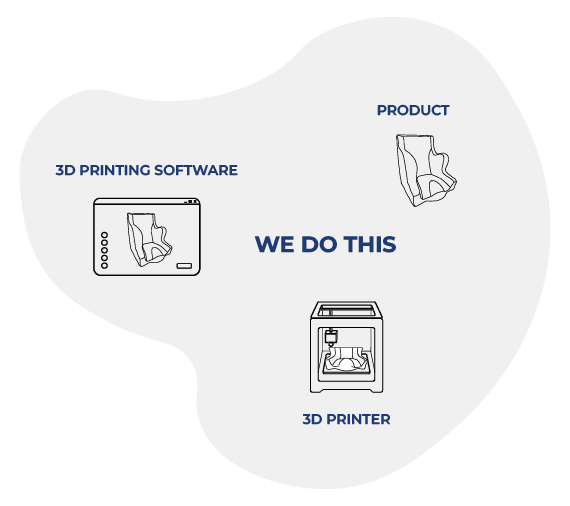

3D Printing Customization Process

- Digital Design – 3D modeling (CAD)

- File Preparation – Slicing and parameter setting

- Printing – Layer-by-layer fabrication

- Post-Processing – Support removal and finishing

- Quality Check – Inspection and verification

III. Material Differences

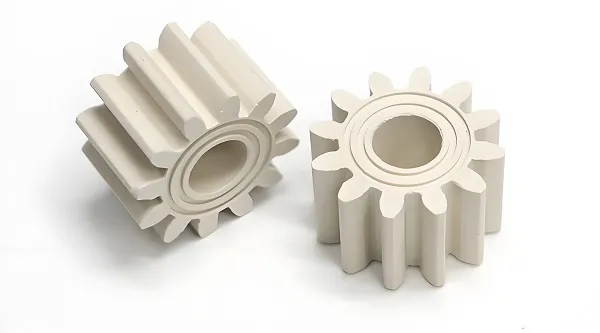

Injection Molding Materials

- Thermoplastics: ABS, PP, PE, PC, PA, POM

- Thermosets: Epoxies, phenolics

- Elastomers: TPU, silicone

- Composites: Glass-filled materials

- Wide material selection

- Consistent material properties

- Higher density and strength

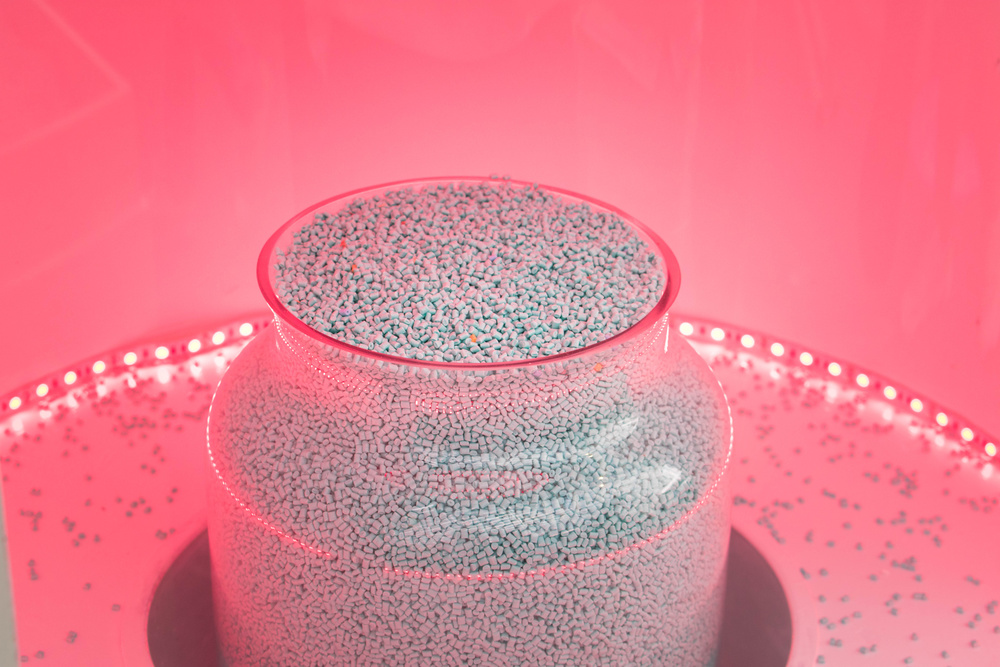

3D Printing Materials

- FDM Materials: PLA, ABS, PETG, TPU

- SLA/DLP Resins: Photopolymers, castable resins

- SLS Materials: Nylon, polyamides

- Specialty Materials: Carbon fiber composites, metal powders

- Rapid material changeover

- Support for functional prototypes

- Unique material combinations

IV. Finished Product Differences

Injection Molded Product Characteristics

- Homogeneous material structure

- Higher tensile strength

- Better impact resistance

- Smooth, consistent finish

- High dimensional accuracy

- Minimal post-processing needed

- Identical parts with tight tolerances

- Excellent repeatability

- Uniform material properties

3D Printed Product Characteristics

- Intricate geometries possible

- Internal channels and hollow structures

- Lattice and topology-optimized designs

- Anisotropic strength (layer direction dependent)

- Potential for layer adhesion issues

- May require post-processing

- Each part can be unique

- Variable properties within single part

- On-demand production capability

V. How to Choose the Right Manufacturing Process

Decision Matrix

|

Factor

|

Injection Molding

|

3D Printing

|

|

Volume

|

High (500+)

|

Low (1-100)

|

|

Lead Time

|

Longer

|

Shorter

|

|

Cost

|

Lower at scale

|

Lower for small batches

|

|

Design Flexibility

|

Limited

|

High

|

|

Material Options

|

Extensive

|

Growing

|

|

Part Strength

|

Higher

|

Good for prototypes

|

Recommended Selection Scenarios

- Production volume exceeds 500 units

- Design is finalized and stable

- Material strength and durability are critical

- Surface finish requirements are high

- Need rapid prototyping or small batches

- Design is still evolving

- Complex geometries are required

- Customization is essential

VI. Surface Finishing

Injection Molding Surface Treatments

- SPI-A1: Mirror polish

- SPI-B1: Semi-gloss

- SPI-C1: Matte finish

- Textured surfaces: Various patterns available

- Painting and coating

- Pad printing

- Hot stamping

- Laser engraving

3D Printing Surface Treatments

- Support removal

- Sanding and polishing

- Chemical smoothing

- Priming and painting

- Vapor smoothing for SLS parts

- Acetone smoothing for ABS

- UV curing for resin parts

- Powder coating for metal parts

VII. Product Characteristics Comparison

Injection Molded Product Characteristics

- Higher tensile strength

- Better impact resistance

- Uniform material distribution

- Higher heat deflection temperature

- Tighter tolerances (±0.02mm)

- Better repeatability

- Minimal warping

- Wide range of engineering plastics

- Food-grade and medical-grade materials

- High-temperature resistant materials

3D Printed Product Characteristics

- Complex internal structures

- Overhangs without supports

- Variable density structures

- Multi-material capabilities

- Rapid design validation

- Fit and form testing

- Functional prototypes

- Concept visualization

- Composite materials

- Conductive filaments

- Biodegradable options

- Metal-infused materials

VIII. Processing Advantages

Injection Molding Advantages

- High production speed

- Low labor requirements

- Minimal material waste

- 24/7 operation capability

- Low per-unit cost at scale

- Long mold lifespan

- High material efficiency

- Reduced post-processing

- Consistent part quality

- Automated inspection possible

- Traceability throughout production

- Process optimization opportunities

3D Printing Advantages

- Instant design-to-part capability

- No tooling required

- Quick design iterations

- Early-stage validation

- Mass customization possible

- Personalized products

- On-demand manufacturing

- Geographical flexibility

- Complex geometries

- Topology optimization

- Lightweight structures

- Product innovation acceleration

IX. Cost-Benefit Analysis

Injection Molding Cost Structure

- Mold design: (2,000-)10,000

- Mold fabrication: (5,000-)50,000

- Equipment setup: (1,000-)5,000

- Material: (0.10-)2.00

- Labor: (0.05-)0.50

- Energy: (0.01-)0.10

- Tooling depreciation: (0.05-)0.50

- Typically around 500-1,000 units

- Lower unit costs as volume increases

- Long-term cost savings for sustained production

3D Printing Cost Structure

- 3D printer: (1,000-)100,000

- Software: (500-)5,000

- Training: (1,000-)5,000

- Material: (0.50-)50.00

- Labor: (0.50-)5.00

- Energy: (0.10-)1.00

- Post-processing: (0.50-)10.00

- No mold costs

- Lower setup costs

- Minimal material waste

- Faster time-to-market

X. Common Processing Issues and Solutions

Injection Molding Common Issues

- Causes: Uneven cooling, material selection

- Solutions: Mold temperature control, material additives, part design optimization

- Causes: Insufficient packing pressure, gate location

- Solutions: Process parameter adjustment, gate redesign, material selection

- Causes: Mold parting line issues, clamping force

- Solutions: Mold maintenance, parameter optimization, secondary trimming

3D Printing Common Issues

- Causes: Temperature settings, material quality

- Solutions: Print temperature adjustment, material drying, print speed optimization

- Causes: Bed adhesion, cooling rates

- Solutions: Heated bed, adhesion promoters, enclosure use

- Causes: Overhang angles, part orientation

- Solutions: Support generation optimization, part reorientation, soluble supports

XI. Xiamen Goldcattle Custom Injection Molding Services

Core Service Offerings

- High-precision plastic components

- Tight tolerance control (±0.005mm)

- Complex geometry manufacturing

- Multi-cavity mold design

- Product design and engineering

- Mold design and fabrication

- Injection molding production

- Assembly and finishing

- International certifications (SGS, RoHS, CE)

- Advanced inspection equipment

- Strict quality control processes

- Reliable supply chain management

Technical Advantages

- 100+ processing machines

- Multi-axis CNC machining centers

- Automated production lines

- Robotic handling systems

- Wide range of engineering plastics

- Custom material formulation

- Color matching capabilities

- Material testing and validation

- Automotive components

- Electronic enclosures

- Medical devices

- Consumer products

XII. How to Choose the Right Manufacturing Solution for You

- What is your production volume? – Small batches favor 3D printing, large volumes favor injection molding

- How stable is your design? – Evolving designs benefit from 3D printing flexibility

- What are your material requirements? – Specialized materials may dictate the process

- What is your timeline? – Urgent projects often use 3D printing for speed

XIII. Call to Action: Contact Us for Professional Advice

- Free manufacturing consultation

- Cost estimation and analysis

- Design for manufacturability review

- Production timeline planning

- Product type and application

- Expected production quantity

- Material requirements

- Delivery time requirements