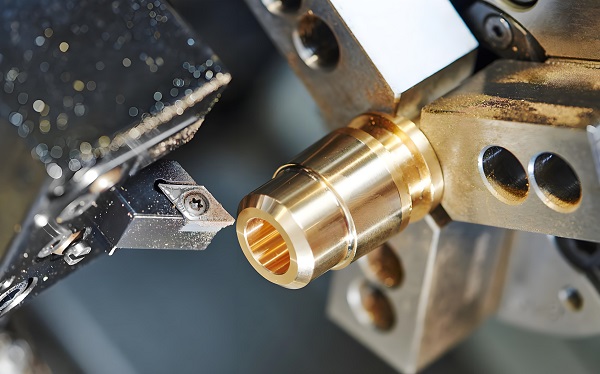

CNC machining technology is the basis of modern manufacturing technology, which controls machine tools for automatic processing through computer programs, so that ordinary machinery is replaced by CNC machinery, greatly enhancing the productivity and processing accuracy of the manufacturing industry. The level and popularity of CNC machining technology has become one of the important symbols to measure a country’s comprehensive national strength and industrial modernization level.

Technical characteristics:

High degree of automation: CNC machining through pre-set programs for automated processing, reducing manual operation and improving production efficiency.

High machining accuracy: CNC machine tools are equipped with high-precision control systems and detection devices, capable of machining high-precision parts.

Strong adaptability: by modifying the machining program, parts of different shapes and sizes can be conveniently processed, which is suitable for multi-species and small batch production.

Reduce the number of fixtures: CNC machining technology reduces the number of fixtures a lot, making the processing of parts with complex shapes do not need complex fixtures.

1.CNC machining system

CNC machining system mainly includes the following aspects of the process:

Practical training of basic skills knowledge: including design analysis, process planning, CNC programming, CNC operation and related principles of learning and practice.

Direct control of local CNC equipment: directly control CNC machine tools for processing through the network or local computer.

Control of remote CNC equipment: receive CNC processing requests and processing codes from remote users, carry out local CNC equipment control, and realize remote control of off-site users.

Networking CNC technology:

With the development of networked technology, CNC machining system has been realized through the network of CNC equipment for direct control and remote monitoring, improving production efficiency and processing accuracy.

2. Reliability of CNC machining

The reliability of CNC machining is mainly affected by the following two factors:

Reliability of CNC machine tools: the performance and quality of CNC machine tools themselves directly affect the reliability of processing.

Whether the combination of machining processes is reasonable: a reasonable combination of machining processes can improve the efficiency and quality of machining and reduce machining errors.

In addition, by strengthening the training and management of operators, it can reduce operational errors and improve the reliability of processing.

3. Market share:

According to a research report by QYResearch, the global CNC machining services market is expected to grow at a CAGR of 8.5% over the next few years, and the market size is projected to reach USD 2.6 billion by 2029. Global CNC machining services manufacturers mainly include Rensselaer, Toolcraft, Xometry, Mechanical Power, etc.

4. Shipment cycle time advantage:

CNC machining has the ability to respond quickly and efficient production, can greatly reduce the product development and manufacturing cycle. Through networked CNC technology, problems in the processing can be found and solved in a timely manner, reducing debugging time and improving production efficiency.

5. After-sales service guarantee

Quality after-sales service is an important part of CNC machining services, mainly including the following aspects:

Telephone consultation and on-site maintenance: provide timely telephone consultation and on-site maintenance services to ensure the normal operation of the equipment.

Professional maintenance team: with experienced technicians, can quickly respond to the user’s maintenance needs, and provide comprehensive maintenance solutions.

Spare parts supply: provide original spare parts to ensure the stability and safety of the equipment.

Warranty service: provide users with comprehensive warranty services to protect the normal use of equipment.

Frequently Asked Questions:

What should I do if the machine tool processing is not accurate?

A: Firstly, check whether the machining program and tool of the machine tool are correct, meanwhile, check whether the motion system of the machine tool is in normal state, if there is any problem, please contact the after-sales service team in time.

How to deal with control system failure?

A: Control system failure is generally caused by system battery failure, electromagnetic interference or system software problems, which need professional technicians to deal with, users can contact the after-sales service team for help.

What should I do if the machining quality is not good?

A: Check whether the position of the tool and fixture is correct, and also check whether the machining program meets the requirements, if there is any problem, please contact the after-sales service team in time.

Conclusion

CNC machining technology plays an increasingly important role in the modern manufacturing industry with its high precision, high efficiency and strong adaptability. Through continuous technological innovation and service optimization, we will provide customers with more high-quality CNC machining services and help the transformation and upgrading of the manufacturing industry.