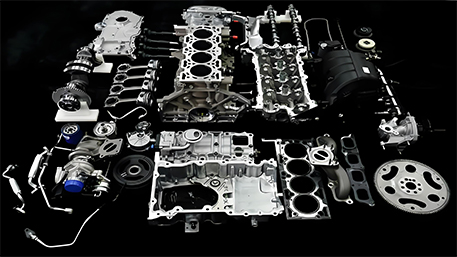

The automotive engine, serving as the “heart” of a vehicle, relies heavily on the precision and performance of its internal parts. From the cylinder block to the piston, from the connecting rod to the crankcase, each component plays an indispensable role. This article will briefly introduce the basic purposes and advantages of automotive engine parts, delve into Xiamen Goldcattle’s unique strengths in customized automotive engine parts, and provide a comparison table of product performance among multiple companies, specifications and dimensions of parts, the customization process, and common questions regarding product customization.

I. Purposes of Automotive Engine Parts

- Cylinder Block: The cylinder block serves as the foundation of the engine, accommodating the piston and forming a sealed combustion chamber with components like the crankcase and cylinder head.

- Crankshaft: The crankshaft connects the piston, connecting rod, and flywheel, transmitting torque and work, serving as the power output component of the engine.

- Connecting Rod: The connecting rod links the piston and crankshaft, converting the reciprocating motion of the piston into the rotational motion of the crankshaft.

- Piston: The piston moves reciprocally within the cylinder block, working with the cylinder head to form a sealed combustion chamber, completing the processes of gas compression and expansion.

- Camshaft: Controls the opening and closing of valves, ensuring smooth progression through intake, compression, combustion, and exhaust processes.

- Oil Pan: Stores engine oil, providing lubrication and cooling for various engine components.

II. Advantages of Automotive Engine Parts

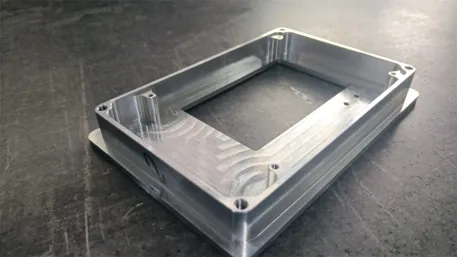

- High Precision: Modern automotive engine parts utilize advanced CNC machining technology, ensuring dimensional and form precision of parts.

- High Strength: Premium materials, such as high-strength alloy steel and aluminum alloy, are employed to ensure stable performance under high loads.

- Long Lifespan: Through rigorous heat treatment, surface treatment processes, and others, parts are enhanced with wear resistance, corrosion resistance, and fatigue resistance.

III. Comparison Table of Product Performance Among Multiple Companies

| Company Name | Cylinder Block Material | Crankshaft Material | Connecting Rod Material | Piston Material | Precision Grade | Lifespan (100,000 km) |

|---|---|---|---|---|---|---|

| Xiamen Goldcattle | Aluminum Alloy | Nodular Iron | Alloy Steel | Aluminum Alloy | IT6 | 100 |

| Company A | Steel | Cast Iron | Cast Iron | Cast Iron | IT7 | 80 |

| Company B | Aluminum Alloy | Cast Aluminum | Aluminum Alloy | Aluminum Alloy | IT6 | 90 |

| Company C | Steel | Nodular Iron | Alloy Steel | Cast Iron | IT7.5 | 75 |

(Note: The above data is for reference only. Specific performance may vary based on product models, processing techniques, and other factors.)

IV. Specifications and Dimensions of Automotive Engine Parts

The specifications and dimensions of automotive engine parts vary depending on vehicle models, engine types, and other factors. For example, a crankshaft’s dimensions may include length, diameter, journal size, and oil hole locations. Specific specifications and dimensions are customized based on customer needs and product design.

V. Customization Process for Automotive Engine Parts

- Needs Communication: Conduct in-depth communication with customers to understand specific needs and expectations.

- Design Proposal: Based on customer needs, design appropriate part drawings and process plans.

- Material Selection: Choose suitable materials according to the operating environment and performance requirements of the parts.

- Processing and Manufacturing: Utilize advanced CNC machining equipment for part processing to ensure precision and quality.

- Quality Inspection: Conduct rigorous quality inspections on parts to ensure compliance with customer requirements.

- Packaging and Shipment: Package qualified parts and deliver them to customers on time.

VI. Common Questions Regarding Product Customization

- Precision Issues: Due to the high requirements for dimensional and form precision of parts, processing errors may occur. Xiamen Goldcattle employs advanced CNC machining technology and rigorous quality control processes to ensure part precision meets customer requirements.

- Material Selection: Different parts have different material requirements, which must be selected based on the operating environment and performance requirements. Xiamen Goldcattle boasts a rich material library and professional material selection experience, providing customers with suitable material recommendations.

- Delivery Time: Since part customization involves design, processing, inspection, and other stages, the delivery time may be relatively long. Xiamen Goldcattle optimizes production processes and improves production efficiency to ensure timely delivery.

In summary, Xiamen Goldcattle possesses unique strengths in customized automotive engine parts. With extensive customization experience, advanced processing technology, and rigorous quality control processes, we provide customers with high-quality, high-precision customized automotive engine parts services.